Will rust fail an MOT?

- Lloyd Saunders

- Dec 16, 2025

- 5 min read

The simple answer is: yes, rust can fail an MOT, but not all rust will result in a failed test. The critical distinction lies in whether the corrosion affects your vehicle's structural integrity and safety systems. Understanding exactly when rust becomes an MOT concern can save you from unexpected failures and potentially dangerous driving conditions.

As automotive rust protection specialists, we regularly encounter vehicle owners who are surprised by rust-related MOT failures. The key is knowing the difference between cosmetic surface rust and the structural corrosion that poses genuine safety risks.

The Difference Between Cosmetic and Structural Rust

Cosmetic rust will not fail your MOT. Minor surface corrosion on visible panels, door frames, or non-structural components is not a concern during the annual test. MOT examiners understand that vehicles, particularly those over three years old, will naturally develop some surface oxidation, especially in the UK's challenging climate.

However, rust becomes a serious MOT issue when it affects specific critical areas of your vehicle. The examination focuses on structural components that are essential for vehicle safety, steering control, braking performance, and occupant protection.

When Rust Causes MOT Failure

According to official MOT inspection guidelines, rust or corrosion will result in test failure when it:

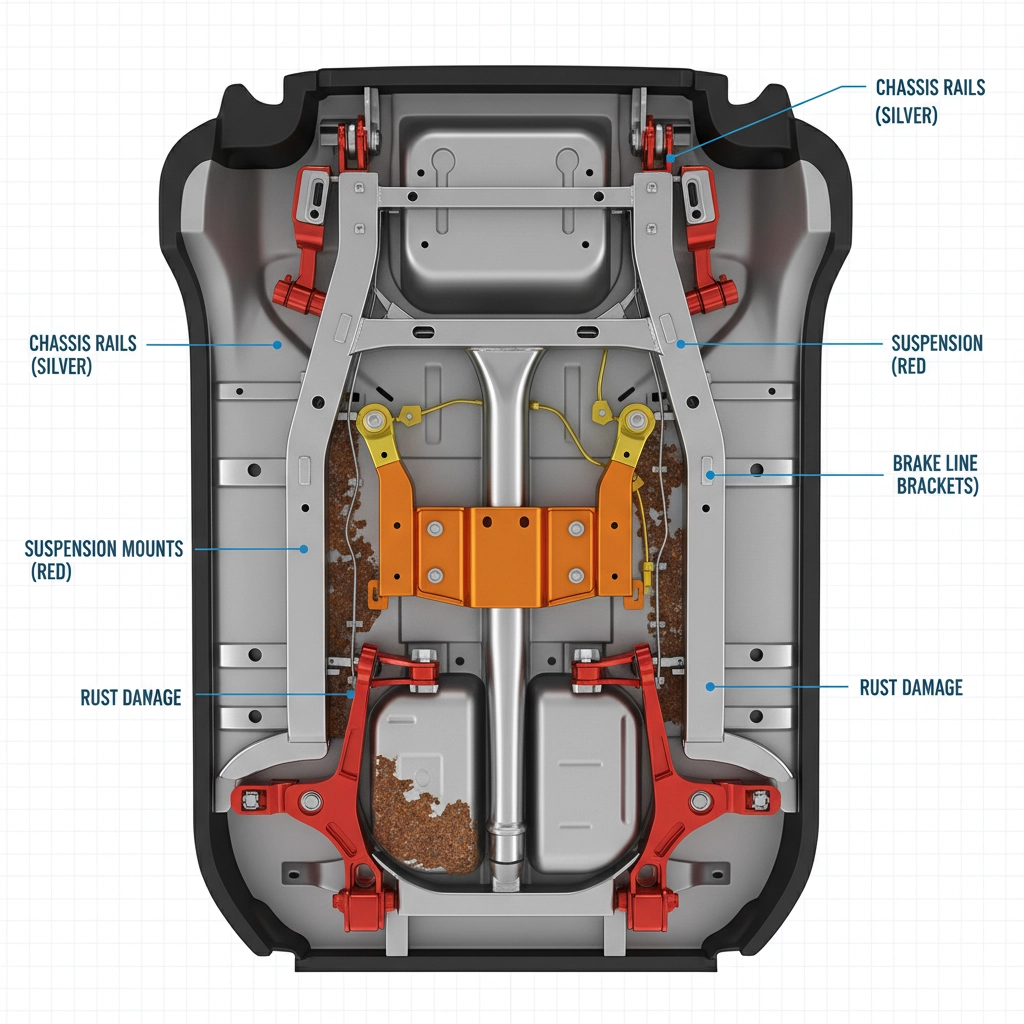

Affects load-bearing or structural components - This includes the chassis, sills, suspension mounting points, subframes, and any component that supports the vehicle's weight or structural integrity.

Weakens prescribed areas - These are sections within 30 centimetres of critical safety components such as brake systems, steering mechanisms, or seat belt anchor points.

Reduces structural rigidity - Corrosion that compromises the vehicle's ability to maintain proper steering geometry or braking stability will result in immediate failure.

Creates sharp edges or projections - Rust that has eaten through metal to create dangerous protrusions poses a risk to pedestrians and other road users.

Compromises safety-critical mounting points - Any corrosion affecting suspension components, steering systems, or braking mechanisms is treated as a major safety defect.

Critical Areas Examined During MOT Testing

MOT examiners pay particular attention to these rust-prone areas:

Chassis and Subframe

The vehicle's main structural framework must remain sound. Significant rust penetration in load-bearing sections of the chassis or subframe will result in failure. Examiners look for holes, excessive thinning, or areas where the metal has lost structural integrity.

Suspension and Steering Mounts

All mounting points for suspension components, shock absorbers, springs, and steering mechanisms are thoroughly inspected. Rust that affects these connections can compromise vehicle handling and safety.

Seat Belt Anchor Points

The mounting points for seat belts must remain structurally sound. Any corrosion that could affect the integrity of seat belt fixings results in immediate failure, as this directly impacts occupant safety in an accident.

Brake System Components

All brake line mounting brackets, brake calliper mounting points, and related hardware are examined for corrosion. Rust affecting braking components is treated as a dangerous defect.

Body Mounts and Structural Joints

Points where the body connects to the chassis, structural joints, and load-bearing connections are inspected for rust penetration that could affect overall vehicle integrity.

Sills and Jacking Points

Door sills and designated jacking points must remain structurally sound. These areas are particularly prone to rust due to their exposure to road spray and water ingress.

MOT Failure Categories for Rust

Rust-related defects are categorised based on their severity:

Dangerous Defects

Rust that poses an immediate safety risk, such as structural failure in critical areas or compromised brake system mounting points. Driving with a dangerous defect is illegal and can result in fines up to £2,500, penalty points, or driving bans.

Major Defects

Significant corrosion that affects safety, environmental standards, or roadworthiness. This includes substantial rust in structural areas that haven't yet reached dangerous levels.

Minor Defects

Rust issues that don't directly affect safety but should be monitored. These don't result in MOT failure but serve as early warnings for future problems.

Advisory Notes

Early-stage corrosion that should be addressed to prevent future deterioration. While not causing failure, advisories highlight areas requiring attention.

Vehicle Age and Rust Expectations

MOT examiners adjust their expectations based on vehicle age and type. A five-year-old family car will be held to different standards than a fifteen-year-old commercial vehicle. However, age never excuses dangerous structural defects.

Older vehicles often receive advisory notes for minor rust issues, but this doesn't mean they're failing the test. These advisories serve as early warnings, allowing owners to address problems before they become serious safety concerns.

Common Rust-Related MOT Failures

Based on our experience with thousands of rust protection treatments, these are the most frequent rust-related failure points:

Rear axle mounting points - Particularly common on older 4x4 vehicles and commercial vans where mounting brackets corrode due to exposure and loading stresses.

Front subframe corrosion - Often affects vehicles that regularly encounter road salt, especially around suspension mounting points and steering rack fixings.

Sill deterioration - Door sills are prone to water ingress and subsequent rust, particularly where drain holes become blocked or damaged.

Brake line mounting brackets - Corrosion of brackets securing brake lines can compromise braking system integrity and always results in failure.

Exhaust mounting points - While not always structural, severely corroded exhaust mountings can create safety hazards and emission control issues.

Preventing Rust-Related MOT Failures

Professional rust prevention is the most effective approach to avoiding MOT failures. Regular application of premium cavity waxes and structural protection treatments significantly extends component life and maintains structural integrity.

Annual inspections allow early identification of problem areas before they develop into MOT failures. Our comprehensive inspection service identifies vulnerable areas and provides targeted protection.

Prompt attention to minor issues prevents small rust spots from developing into structural problems. Early intervention is always more cost-effective than major repairs.

Quality rust protection treatments using products like Dinitrol provide long-term protection for critical structural areas. Our Life Long Dinitrol® treatments offer comprehensive coverage with our Rustec Guarantee.

Regular maintenance including cleaning drainage points, repairing paint damage, and maintaining protective treatments keeps vehicles in optimal condition.

Professional Assessment and Treatment

If your vehicle has failed its MOT due to rust, professional assessment is essential. Our qualified technicians can evaluate the extent of corrosion, determine repair requirements, and implement comprehensive protection strategies.

We provide detailed inspection reports with photographic documentation, allowing you to understand exactly what needs attention and why. This transparency helps you make informed decisions about repairs and future protection.

The Cost of Prevention vs Repair

Preventing rust-related MOT failures is significantly more cost-effective than addressing structural repairs. Professional rustproofing treatments represent excellent value when compared to welding work, component replacement, or vehicle depreciation due to corrosion damage.

Our comprehensive treatment packages include thorough undercarriage cleaning, professional application of premium protection products, and ongoing maintenance support. This proactive approach ensures your vehicle maintains its structural integrity and passes MOT tests year after year.

When to Seek Professional Help

If you've received an MOT advisory for rust, or if you're concerned about corrosion on your vehicle, professional assessment is recommended. Early intervention prevents minor issues from developing into expensive structural problems.

Our expert team provides honest assessments and practical solutions. We'll explain exactly what's needed, why it's important, and how our treatments protect your investment long-term.

For vehicles approaching MOT due dates, particularly those over five years old or regularly used in challenging conditions, preventive rust protection offers excellent peace of mind. Our treatments ensure your vehicle remains roadworthy and maintains its structural integrity.

Contact Rustec today for expert rust assessment and professional protection treatments. Don't let preventable corrosion compromise your vehicle's safety or roadworthiness – invest in proven rust prevention that works.

Comments