Why your van is rusting underneath after 3 years

- Lloyd Saunders

- Nov 19, 2025

- 5 min read

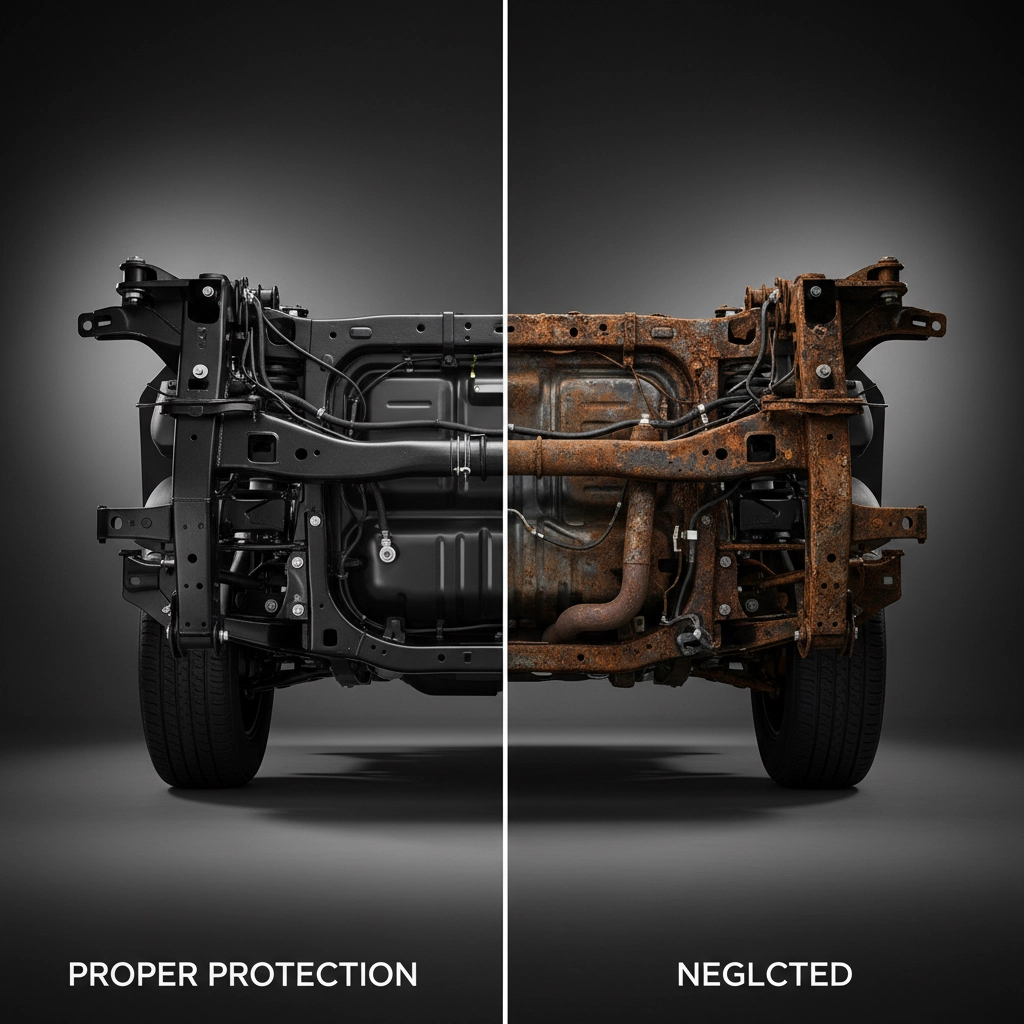

Discovering rust underneath your three-year-old van can be both shocking and frustrating. After all, you've invested significantly in what should be a reliable workhorse, yet here you are facing corrosion that threatens both safety and resale value. Unfortunately, this scenario is far more common than manufacturers would have you believe, particularly in the UK's challenging climate conditions.

The Reality of Modern Van Construction

Today's commercial vans are built to different standards than their predecessors. While manufacturers focus heavily on fuel efficiency, payload capacity, and competitive pricing, underbody rust protection often receives minimal attention. Most factory-applied coatings are designed to meet basic warranty requirements rather than provide comprehensive long-term protection against the UK's harsh road conditions.

The thin layer of wax-based protection applied at the factory typically begins deteriorating within the first 18-24 months of regular use. This leaves your van's critical structural components exposed to the elements precisely when you need reliable transportation the most.

Why UK Roads Are Particularly Destructive

British road conditions create the perfect storm for accelerated rust formation. During winter months, local authorities apply approximately 2.3 million tonnes of rock salt across UK roads – a necessary measure for safety, but devastating for vehicle longevity. This salt doesn't simply wash away after winter; it accumulates in crevices, joints, and hollow sections of your van's chassis.

Road grit compounds the problem by creating thousands of tiny chips and scratches in protective coatings. Each microscopic breach becomes an entry point for moisture and salt, initiating the oxidation process that transforms steel into rust. Even during summer months, frequent rainfall keeps these corrosive elements active rather than allowing them to dry out completely.

The UK's high humidity levels mean that even when it's not actively raining, your van's undercarriage remains damp for extended periods. This persistent moisture, combined with temperature fluctuations, creates ideal conditions for rust to establish and spread rapidly through interconnected metal sections.

Critical Vulnerability Points on Three-Year-Old Vans

Professional underbody inspections reveal consistent patterns of rust development across different van models. The rear leaf spring mounting points and chassis crossmembers typically show the first signs of significant corrosion. These areas trap moisture and debris while being constantly flexed during normal operation, accelerating the breakdown of factory protection.

Door frames and sill sections represent another major concern. Water enters through worn door seals and drainage holes, pooling in enclosed spaces where it cannot evaporate. Without proper cavity protection, these areas develop serious structural rust that can compromise safety and lead to MOT failures.

The fuel tank mounting area deserves particular attention. Salt spray and road debris accumulate around mounting brackets and straps, leading to corrosion that can result in expensive repairs and potential safety hazards. Many van owners overlook this area until damage becomes severe enough to affect fuel system integrity.

Manufacturer Protection Gaps

Major van manufacturers apply basic protection primarily to visible areas and known problem zones identified through warranty claims. However, this reactive approach leaves many critical areas under-protected. Hollow chassis sections, for example, typically receive minimal internal coating despite being impossible to inspect or treat once corrosion begins.

The quality of factory-applied protection varies significantly between production batches and facilities. Cost-cutting measures often result in thinner coating applications or the use of lower-grade materials that provide adequate short-term protection but fail prematurely under real-world conditions.

Additionally, manufacturer warranties typically exclude corrosion damage caused by environmental factors – precisely the conditions your van encounters daily on UK roads. This means that even if rust develops within the warranty period, you're likely responsible for repair costs.

The Compounding Effect of Commercial Use

Commercial vans face significantly more challenging conditions than private vehicles. Daily loading and unloading creates chassis flex that accelerates coating failure. Frequent stop-start driving in urban environments exposes the undercarriage to repeated thermal cycling, causing protective materials to crack and separate from metal surfaces.

Many commercial operators focus primarily on mechanical maintenance while overlooking rust prevention. This short-sighted approach often results in vehicles that run well mechanically but face early retirement due to structural corrosion – a costly oversight that affects both operational efficiency and resale value.

Environmental Factors Beyond Road Salt

Coastal areas present additional challenges through salt-laden air that accelerates corrosion even when vehicles aren't driven on treated roads. Urban pollution creates acid rain conditions that gradually neutralise alkaline protective coatings, leaving metal surfaces vulnerable to oxidation.

Industrial areas expose vans to airborne chemicals and particulates that can interact with moisture to create particularly aggressive corrosive conditions. Even seemingly benign environments like construction sites generate dust and debris that can trap moisture against protective coatings, creating localised corrosion cells.

Early Warning Signs to Monitor

Regular inspection of your van's undercarriage can identify developing problems before they become serious safety concerns. Surface rust appearing on crossmembers, mounting brackets, or exhaust components indicates that protective coatings have failed and active corrosion is underway.

Rust staining around bolt holes or joints suggests that moisture is penetrating into structural connections. These areas require immediate attention to prevent spread into inaccessible hollow sections where repair becomes impossible without major disassembly.

Pay particular attention to any areas where different metals meet, as galvanic corrosion can occur rapidly when dissimilar metals are connected in the presence of moisture and salt. These joints often show rust damage earlier than surrounding areas.

Professional Assessment and Solutions

A comprehensive underbody inspection by rust prevention specialists can identify current damage extent and recommend appropriate treatment strategies. Professional assessment includes cavity probing to detect hidden corrosion and evaluation of remaining factory protection effectiveness.

Modern rust prevention systems like Dinitrol provide superior long-term protection compared to factory coatings. These professional-grade treatments penetrate existing rust to halt further progression while providing comprehensive coverage of vulnerable areas often missed during manufacturing.

Long-Term Protection Strategy

Effective rust prevention requires a systematic approach that addresses both current corrosion and future protection needs. Professional cavity wax treatment provides internal protection for hollow chassis sections while external coatings shield exposed surfaces from road salt and moisture.

Annual inspection and maintenance of rust prevention systems ensures continued effectiveness throughout your van's working life. This proactive approach typically costs significantly less than reactive repairs while maintaining vehicle reliability and resale value.

Taking Action Before It's Too Late

If your three-year-old van is showing signs of undercarriage rust, immediate professional assessment is essential. Early intervention can halt corrosion progression and provide effective long-term protection, while delayed action often results in expensive structural repairs or premature vehicle replacement.

At Rustec, our comprehensive underbody inspection service provides detailed documentation of current corrosion status along with tailored treatment recommendations. Our experienced technicians use professional-grade Dinitrol products to deliver lasting protection backed by our comprehensive guarantee.

Don't let preventable rust damage compromise your van's safety, reliability, or value. Contact Rustec today for your free underbody inspection and discover how professional rust prevention can protect your investment for years to come. Our expert team will assess your van's specific needs and provide a detailed treatment plan designed to halt existing corrosion while preventing future damage.

Your van represents a significant investment in your business operations. Protect that investment with proven rust prevention solutions from the UK's leading specialists in automotive corrosion control.

Comments