Why new cars still need rustproofing in the UK

- Lloyd Saunders

- Nov 1, 2025

- 5 min read

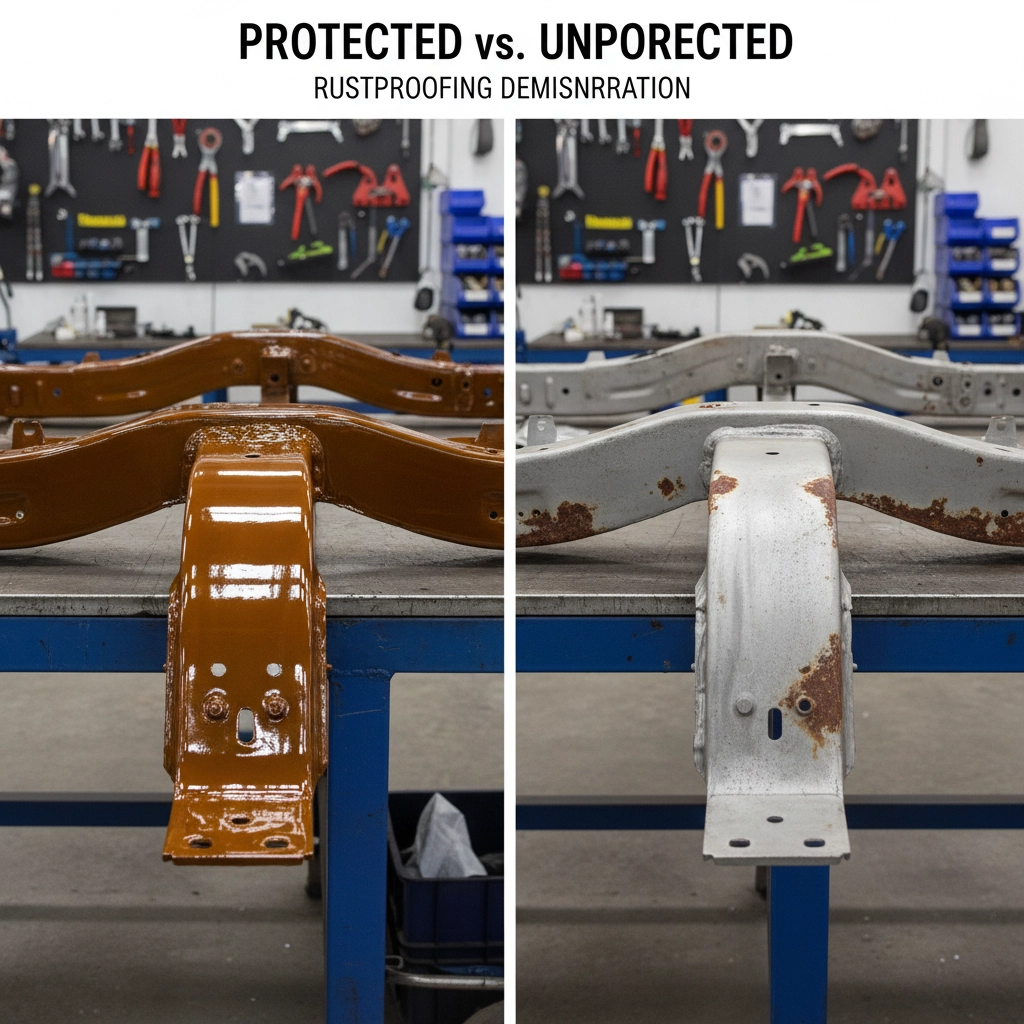

Many new car owners believe their vehicle is immune to rust thanks to modern manufacturing techniques and factory coatings. This misconception costs thousands of drivers significant money in repairs and dramatically reduces their vehicle's lifespan and resale value. The reality is that new cars in the UK face unique challenges that make professional rustproofing not just beneficial, but essential for long-term protection.

The UK's Aggressive Corrosive Environment

The United Kingdom presents one of the most challenging environments for vehicle corrosion in Europe. Our climate combines three of rust's most powerful accelerators: persistent moisture, freezing temperatures, and extensive use of road salt during winter months.

Salt: The Silent Destroyer

During winter, UK roads receive millions of tonnes of salt designed to improve driving safety. However, this same salt creates an aggressive corrosive environment that attacks even the most modern vehicle protection systems. Salt doesn't simply wash away after winter: it accumulates in hidden areas, continuing its destructive work throughout the year.

Year-Round Moisture Exposure

Britain's famously damp climate means vehicles rarely experience extended dry periods that allow moisture to fully evaporate from vulnerable areas. This constant dampness accelerates corrosion processes, particularly in areas where water can become trapped behind trim pieces or in structural cavities.

Why Modern Manufacturing Isn't Enough

While contemporary vehicles benefit from improved paint systems, better sealing techniques, and advanced materials, these improvements haven't eliminated rust vulnerability: they've simply delayed its onset and changed where it occurs.

Factory Protection Limitations

Manufacturers focus their corrosion protection efforts on visible areas and structural components covered by warranty obligations. However, comprehensive coverage of all vulnerable areas would significantly increase production costs, making vehicles less competitively priced. Factory rustproofing typically covers major structural elements but leaves many susceptible areas with minimal protection.

Design Compromises

Modern vehicle design prioritises aerodynamics, weight reduction, and manufacturing efficiency. These requirements often create areas where water, salt, and debris can accumulate. Complex underbody panels, increased use of dissimilar metals, and extensive electrical systems all create new vulnerability points that didn't exist in simpler vehicle designs.

Critical Vulnerability Areas on New Vehicles

Even the newest vehicles have specific areas where corrosion protection is inadequate for UK conditions. Understanding these vulnerable zones explains why additional protection is essential.

Chassis and Subframes

The vehicle's chassis and subframes face constant exposure to road spray containing salt, moisture, and abrasive particles. While factory coatings provide initial protection, they're designed for moderate conditions, not the aggressive UK environment. Chassis rails, suspension mounting points, and structural joints are particularly susceptible to corrosion initiation.

Wheel Arches and Inner Wings

Wheel arches create natural collection points for salt-laden water, mud, and debris thrown up by tyres. The constant bombardment from road materials gradually damages factory coatings, exposing metal to aggressive corrosive elements. Inner wing areas are particularly vulnerable as they're difficult to inspect and clean regularly.

Hidden Structural Cavities

Modern vehicles contain numerous hollow sections, door frames, and structural cavities where moisture can enter but struggle to escape. These areas often receive minimal factory protection as they're considered "sealed" systems. However, water ingress through drainage holes, trim attachments, or microscopic gaps creates perfect conditions for concealed corrosion.

The Hidden Threat: Water Penetration

Contemporary vehicle design uses extensive plastic trim, underbody panels, and aerodynamic covers. While these components improve efficiency and appearance, they can trap moisture and debris against metal surfaces, creating localised corrosion environments that remain hidden until significant damage occurs.

Water infiltration behind plastic trim pieces is particularly problematic as it creates persistent dampness that prevents natural drying. This trapped moisture, combined with salt residue and organic debris, accelerates corrosion processes in areas that appear protected from external view.

Imported Vehicle Challenges

Many popular vehicles sold in the UK, particularly Japanese models renowned for reliability, are designed for their home market's milder climate conditions. These vehicles often arrive with rustproofing specifications unsuitable for UK conditions, making additional protection particularly crucial.

Vehicles manufactured for markets with minimal winter salt use or consistently dry climates lack the comprehensive undercarriage protection needed for UK roads. This explains why certain models develop premature rust problems despite excellent mechanical reliability records.

The Economics of Prevention

Professional rustproofing represents exceptional value when compared to the cost of addressing established corrosion. Rust damage rapidly escalates from surface staining to structural problems requiring extensive welding, panel replacement, or component renewal.

Repair Costs vs Prevention Investment

A comprehensive rustproofing treatment costs significantly less than repairing even minor structural rust damage. Welding repairs, replacement panels, and associated labour costs quickly exceed the investment in quality prevention. Additionally, vehicles with rust damage suffer dramatically reduced resale values, making rustproofing a sound financial investment.

Warranty Limitations

Vehicle manufacturers typically warrant against "perforation" rust: complete holes through metal panels. However, this warranty doesn't cover surface corrosion, structural weakening, or aesthetic damage that occurs before perforation develops. Professional rustproofing protects against all forms of corrosion, not just the specific conditions covered by manufacturer warranties.

When Prevention Becomes Critical

The optimal time for rustproofing is immediately after purchase, while factory coatings remain intact and no corrosion has initiated. Once rust begins, treatment becomes remediation rather than prevention, requiring additional preparation work and potentially compromising long-term effectiveness.

New vehicle rustproofing allows comprehensive coverage of all vulnerable areas using the most effective products and application techniques. This proactive approach ensures maximum protection throughout the vehicle's service life.

Professional Application Advantages

Quality rustproofing requires specialist knowledge, equipment, and products unavailable to general automotive services. Professional application ensures complete coverage, appropriate product selection for specific applications, and proper preparation of surfaces.

Comprehensive Coverage System

Professional rustproofing treatments address all vulnerability points through systematic application of specialised products. Cavity waxes protect internal structures, underseal guards exposed surfaces, and penetrating treatments reach areas inaccessible to standard application methods.

Premium Product Selection

Leading rustproofing systems like Dinitrol represent decades of research and development specifically focused on corrosion prevention. These products offer superior adhesion, flexibility, and longevity compared to generic treatments, providing genuine long-term protection rather than temporary coverage.

Take Action Today

Your new vehicle represents a significant investment that deserves comprehensive protection. Every day of UK driving without adequate rustproofing exposes your vehicle to cumulative damage that becomes increasingly expensive to address.

Rustec's comprehensive new vehicle rustproofing service provides lifetime protection using premium Dinitrol products applied by certified specialists. Our systematic approach ensures complete coverage of all vulnerable areas, backed by our exclusive guarantee.

Don't wait for the first signs of corrosion to appear. Contact Rustec today to schedule your new vehicle rustproofing appointment and secure your investment against the UK's aggressive corrosive environment. Professional protection applied now prevents costly repairs later and maintains your vehicle's value throughout its service life.

Book your rustproofing consultation today( your future self will thank you.)

Comments