Why do Defenders rust so badly?

- Lloyd Saunders

- Nov 25, 2025

- 5 min read

Land Rover Defenders have earned a legendary reputation for their off-road capabilities and rugged durability. However, these iconic vehicles are equally notorious for their susceptibility to rust and corrosion. Understanding why Defenders rust so badly is crucial for current and prospective owners who want to protect their investment and maintain their vehicle's structural integrity for years to come.

The rust problem with Defenders isn't simply due to age or neglect: it's a fundamental issue rooted in design flaws, manufacturing processes, and construction methods that create ideal conditions for corrosion to develop and spread rapidly throughout the vehicle's structure.

Design and Construction Vulnerabilities

The primary reason Defenders rust so extensively lies in their fundamental construction methodology. Unlike modern vehicles that benefit from advanced corrosion-resistant materials and improved manufacturing techniques, Defenders were built using traditional methods that prioritise functionality over long-term corrosion resistance.

The chassis and bodywork feature numerous cavities, layers, and joints where moisture, salt, and debris can accumulate. These hidden spaces create perfect microenvironments for rust to develop, often remaining undetected until significant structural damage has occurred. The firewall, described by experts as the "backbone" of the vehicle, consists of multiple steel layers that trap moisture and road salt, accelerating the corrosion process.

Additionally, Defenders utilise dissimilar metals in their construction: primarily aluminium body panels mounted on steel chassis components. Where these different metals meet, galvanic corrosion occurs at an accelerated rate. This electrochemical reaction between aluminium and steel creates weak points throughout the vehicle's structure, making these junction areas particularly vulnerable to rapid deterioration.

Critical Rust-Prone Areas

Several specific locations on Defenders are notoriously susceptible to rust development, often requiring attention within the first few years of ownership.

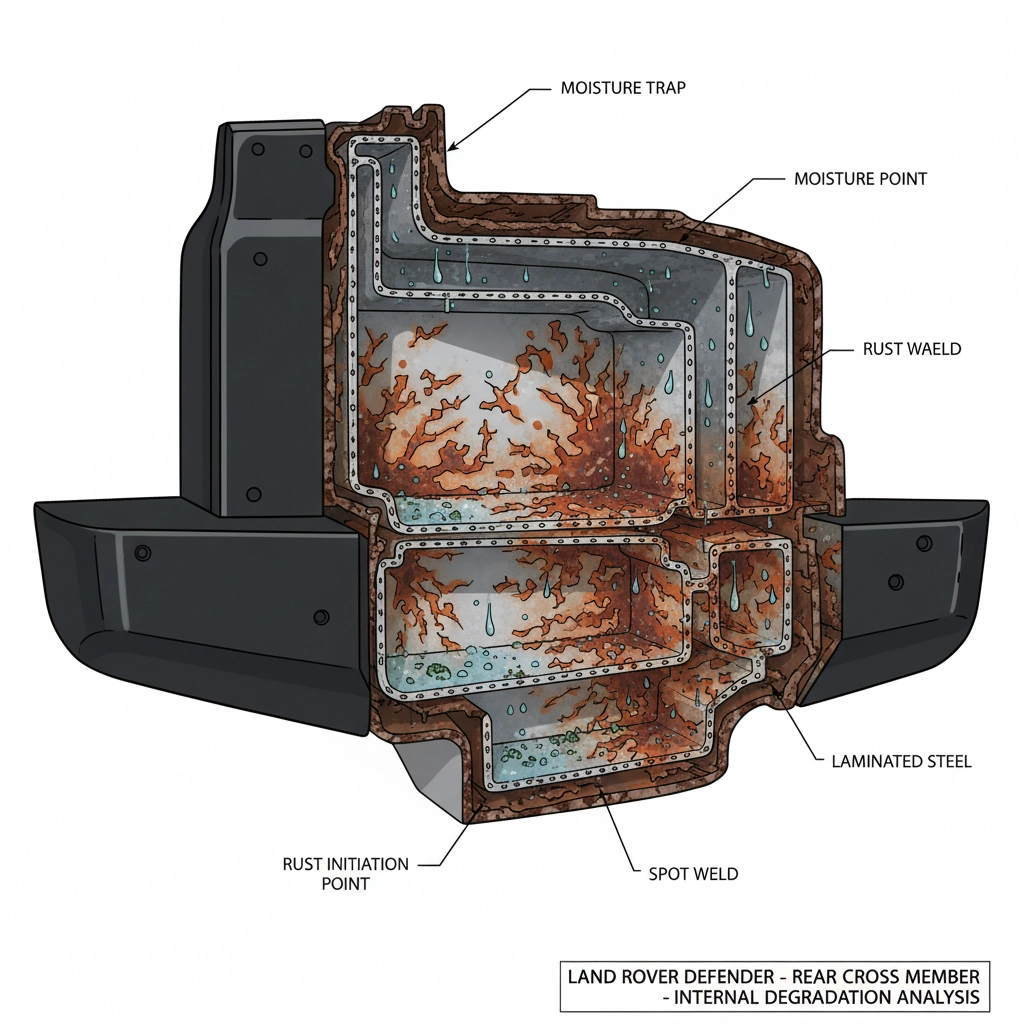

Rear Cross Member The rear x member is typically the first area to show significant rust damage. This component features a complex shape constructed from multiple layers of metal that are spot-welded or plug-welded together. When moisture, road salt, dirt, and debris penetrate between these layers: where no protective paint exists: corrosion begins rapidly and spreads throughout the structure.

Foot Wells and Floor Sections The foot wells present another critical vulnerability. Each corner consists of double-layer steel sections that are spot-welded together during manufacture. Rust initiates inside these sandwiched layers where protective coatings cannot reach, then progresses outward as the external paint develops cracks and deteriorates, allowing further moisture penetration.

Bulkhead and Chassis Rails The bulkhead area, where the engine bay meets the passenger compartment, experiences significant stress and is exposed to heat, moisture, and road contaminants. The chassis rails that run along the vehicle's length contain numerous brackets, mounting points, and structural reinforcements that create moisture traps and corrosion initiation sites.

Outriggers and Cross Members The removable gearbox cross member mounting areas are particularly problematic, as moisture becomes trapped between metal layers during assembly. The mid cross member, where the rear A-frame mounts, features numerous gussets and flanges that collect dirt, salt, and moisture over time.

Manufacturing and Assembly Issues

The manufacturing processes used during Defender production contribute significantly to their rust susceptibility. Understanding these factory-level deficiencies helps explain why even low-mileage, well-maintained examples can develop serious corrosion issues.

Inadequate Protective Coatings Defender chassis receive only a thin layer of primer before being assembled and bonded to the body structure. This minimal protection is insufficient for long-term corrosion resistance, particularly given the harsh conditions these vehicles often encounter. No additional seam sealing or moisture barriers are applied during manufacturing, leaving joints and seams vulnerable to water ingress.

Aluminium Panel Defects The aluminium body panels, while theoretically more corrosion-resistant than steel, develop pinholes during the manufacturing process. These microscopic defects allow moisture to penetrate behind the panels, causing corrosion from the inside out. As this hidden corrosion progresses, paint begins to bubble and crack, revealing the extent of the internal damage.

Welding and Assembly Practices Factory welding procedures apparently did not include proper sand blasting of weld areas, leaving welding flux residue that actively accelerates corrosion. These chemical residues create acidic conditions that promote rapid rust development around weld joints: critical structural areas of the vehicle.

Environmental Factors and Accelerated Corrosion

The UK's challenging driving environment significantly accelerates Defender rust development. Road salt applications during winter months, combined with frequent rainfall and high humidity, create ideal conditions for corrosion.

Coastal areas present additional challenges, with salt-laden air providing constant exposure to corrosive elements. Off-road usage, while the intended purpose for many Defenders, exposes the vehicle to mud, standing water, and debris that can damage protective coatings and create new moisture retention areas.

The combination of these environmental factors with the vehicle's inherent design vulnerabilities creates a perfect storm for rust development that can compromise structural integrity within just a few years of ownership.

Professional Rustproofing: The Comprehensive Solution

Given the extensive rust vulnerabilities inherent in Defender construction, professional rustproofing treatment represents the most effective method for protecting these vehicles long-term. Our comprehensive rustproofing process addresses the fundamental design flaws that make Defenders so susceptible to corrosion.

Advanced Cavity Wax Treatment Professional cavity wax application penetrates into the hidden spaces and cavities where factory protection is inadequate or non-existent. Using specialised application equipment, we ensure complete coverage of internal surfaces, creating a moisture barrier that prevents corrosion initiation in these critical areas.

Comprehensive Undercarriage Protection Our thorough undercarriage treatment begins with meticulous cleaning to remove existing contaminants and assess the current condition. We then apply premium-grade protective coatings that provide superior adhesion and long-term durability compared to factory applications.

Targeted Problem Area Treatment We pay particular attention to known problem areas such as cross members, outriggers, and bulkhead sections, ensuring these vulnerable locations receive enhanced protection. Our treatment methodology addresses the specific design flaws that make these areas so susceptible to corrosion.

Long-Term Protection and Maintenance

Professional rustproofing provides comprehensive protection, but ongoing maintenance ensures optimal performance throughout the vehicle's life. Regular inspection of treated areas, particularly after extended off-road use or winter driving, helps identify any areas requiring attention before significant damage occurs.

Our rustproofing treatments are designed to provide long-lasting protection, with many formulations offering multi-year effectiveness. However, the harsh conditions Defenders often encounter may require periodic reapplication in high-stress areas to maintain optimal protection levels.

Investment Protection Proper rustproofing treatment significantly extends vehicle life and maintains resale value. Given the rising values of good-condition Defenders, particularly early models, professional corrosion protection represents a sound financial investment that pays dividends throughout ownership.

Conclusion

Land Rover Defenders rust badly due to fundamental design flaws, manufacturing deficiencies, and construction methods that create ideal conditions for corrosion development. The combination of dissimilar metals, inadequate factory protection, trapped moisture areas, and exposure to harsh environmental conditions makes professional rustproofing essential for long-term vehicle preservation.

Understanding these vulnerabilities empowers Defender owners to take proactive steps to protect their vehicles. Professional rustproofing treatment addresses the root causes of Defender corrosion, providing comprehensive protection that extends vehicle life and maintains structural integrity for years to come.

For expert rustproofing treatment that protects your Defender against its inherent corrosion vulnerabilities, contact our specialists to discuss the most appropriate protection strategy for your specific vehicle and usage requirements.

Comments