What is the difference between Dinitrol ML and 4941?

- Lloyd Saunders

- Nov 15, 2025

- 5 min read

When selecting premium rust prevention products for your vehicle, understanding the specific roles of Dinitrol ML and Dinitrol 4941 is essential for achieving comprehensive, long-lasting corrosion protection. These two industry-leading products work synergistically but serve distinctly different purposes in a professional rustproofing system.

Both products represent the pinnacle of German engineering excellence, yet their formulations, application methods, and protective mechanisms differ significantly. This detailed comparison will equip you with the technical knowledge needed to make informed decisions about your vehicle's rust prevention strategy.

Understanding Dinitrol ML: The Penetrating Foundation

Dinitrol ML functions as a thin, low-viscosity cavity wax specifically engineered for deep penetration and comprehensive coverage. This all-season product requires no pre-heating, making it exceptionally practical for professional application across varying temperature conditions.

The ML formulation's exceptional creeping properties allow it to migrate into the smallest crevices, seams, and cavity spaces where moisture typically accumulates. Its ultra-thin consistency enables thorough saturation of complex geometric areas that thicker products cannot reach effectively.

Key Characteristics of Dinitrol ML

Viscosity and Flow Properties: The low-viscosity formulation ensures ML penetrates deeply into existing corrosion and displaces moisture from metal surfaces. This characteristic makes it particularly effective for treating areas with established surface oxidation.

Adhesion Promotion: ML serves as a critical adhesion promoter when used beneath heavier protective coatings. The product chemically bonds to metal surfaces and provides an optimal foundation for subsequent coating applications.

All-Weather Application: Unlike temperature-sensitive alternatives, ML maintains consistent application properties across a wide temperature range, ensuring reliable performance regardless of seasonal conditions.

Corrosion Inhibition: The formulation includes advanced corrosion inhibitors that actively neutralise existing rust and prevent further oxidation processes at the molecular level.

Dinitrol 4941: The Robust Protective Barrier

Dinitrol 4941 represents a fundamentally different approach to corrosion protection, functioning as a heavy-duty, solvent-based underbody coating with a sophisticated bitumen base. This thixotropic formulation creates a tough, elastic, and waxy protective film designed to withstand mechanical abrasion and environmental assault.

The black, durable coating provides exceptional resistance against stone chip damage, road salt exposure, and moisture ingress while maintaining flexibility to accommodate normal chassis movement and thermal expansion.

Advanced Properties of Dinitrol 4941

Thixotropic Behaviour: The unique thixotropic properties mean 4941 flows easily during application but quickly develops structural integrity once applied, preventing unwanted dripping or migration.

Self-Healing Technology: A remarkable feature of 4941 is its self-healing capability. The coating maintains a slightly wet underlayer that allows minor chips or scratches to seal automatically, preserving protective integrity over time.

Abrasion Resistance: The robust formulation withstands mechanical damage from road debris, providing long-term protection for high-wear underbody components.

Chemical Resistance: The bitumen-based chemistry offers superior resistance to road chemicals, including de-icing salts and automotive fluids that commonly cause corrosion.

Critical Differences: ML vs 4941 Comparison

Viscosity and Application Characteristics

The most fundamental difference lies in viscosity. ML operates at extremely low viscosity, flowing like water to penetrate microscopic spaces, while 4941 maintains high viscosity for substantial film thickness and robust barrier protection.

Protective Mechanisms

Dinitrol ML works through penetration and displacement, driving out moisture and creating a thin protective barrier within confined spaces. Dinitrol 4941 functions as a sacrificial barrier coating, absorbing impact and chemical attack before it reaches the underlying metal.

Temperature Requirements

ML requires no heating for application, maintaining consistent flow properties across temperature ranges. Traditional heavy-duty products may require warming, but 4941's advanced formulation allows room-temperature application while maintaining optimal protective properties.

Colour and Appearance

ML dries to a thin, relatively clear film that preserves the natural appearance of treated surfaces. 4941 creates a distinctive black coating that clearly indicates treated areas and provides visual confirmation of coverage quality.

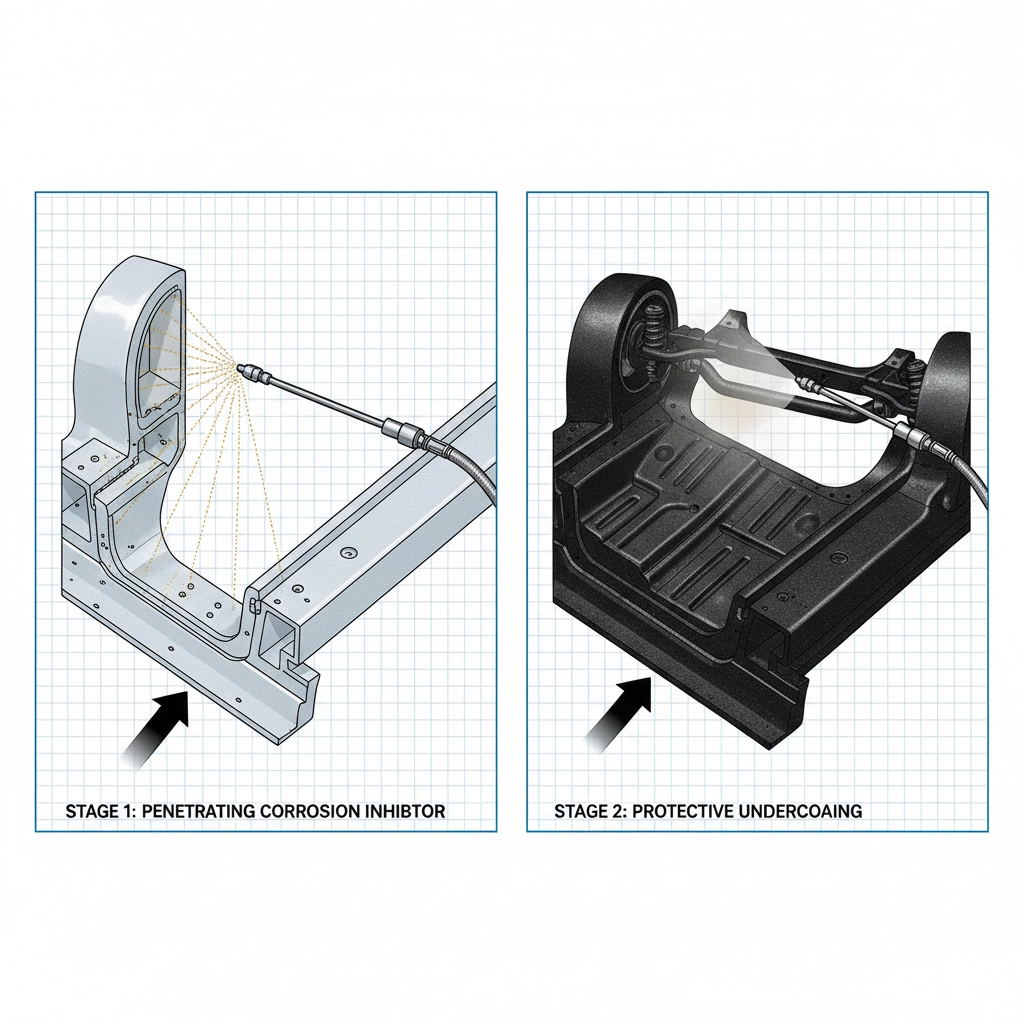

Strategic Application: The Two-Stage System

Professional rustproofing achieves optimal results through strategic product layering, utilising each formulation's specific strengths for comprehensive protection.

Stage One: ML Penetration Treatment

The initial application focuses on Dinitrol ML penetration into all accessible cavities, seams, and crevice areas. This stage addresses existing corrosion, displaces moisture, and prepares surfaces for the protective barrier coating.

Professional technicians apply ML using specialised spray equipment designed for thin-film application, ensuring thorough coverage without waste or oversaturation.

Stage Two: 4941 Barrier Protection

Following ML curing, Dinitrol 4941 application creates the primary protective barrier across exposed underbody surfaces. This heavy-duty coating provides the mechanical protection and chemical resistance necessary for long-term durability.

The two-coat 4941 system ensures adequate film thickness while maintaining the self-healing properties that distinguish this premium product from conventional alternatives.

Application Scenarios: Choosing the Right Product

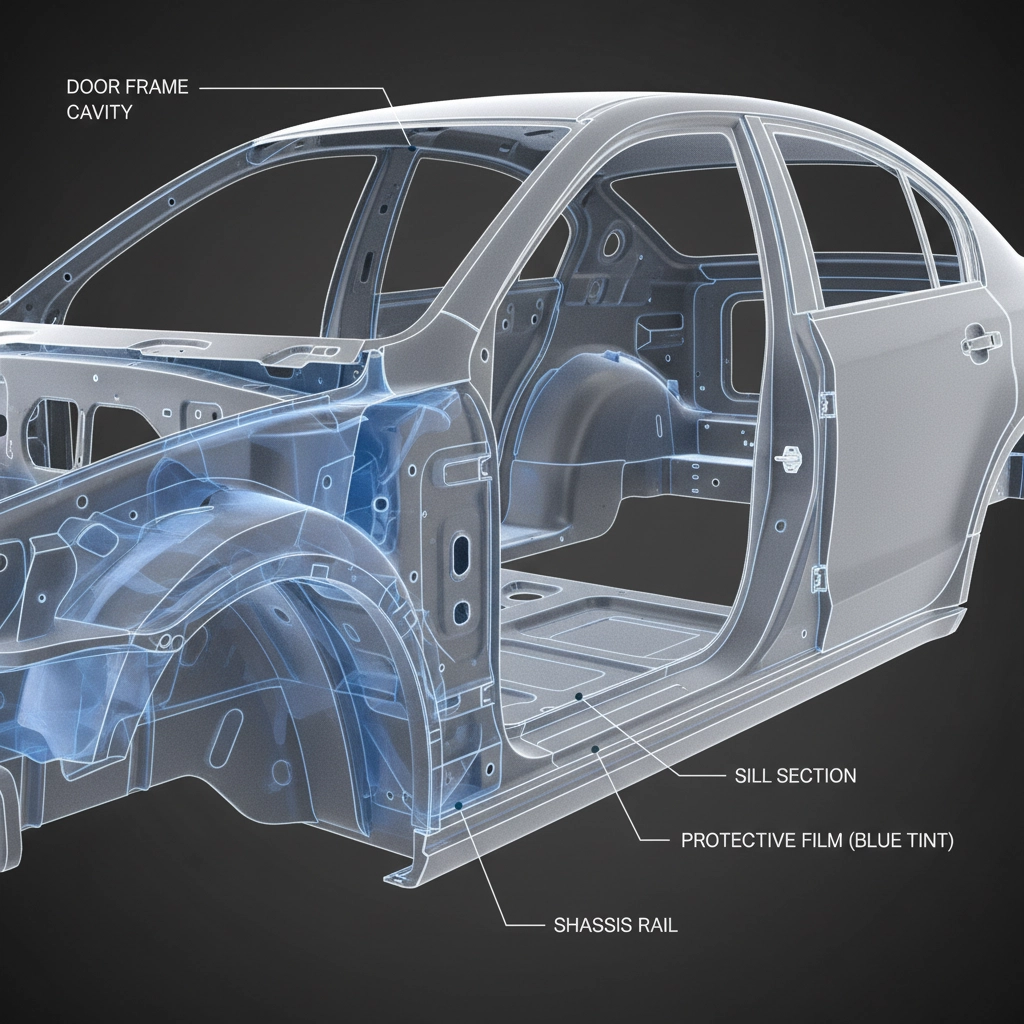

Cavity and Hidden Area Treatment

Dinitrol ML excels in confined spaces where penetration is critical: door frames, sill sections, chassis rails, and complex mechanical assemblies. The product's ability to reach and treat areas inaccessible to thicker coatings makes it indispensable for comprehensive rust prevention.

Exposed Underbody Protection

Dinitrol 4941 dominates exposed underbody applications where mechanical protection and chemical resistance are paramount. Suspension components, chassis rails, fuel tanks, and exhaust systems benefit from the robust protection only heavy-duty barrier coatings can provide.

Combined Treatment Strategy

The most effective approach utilises both products systematically: ML for penetration and preparation, followed by 4941 for barrier protection. This comprehensive strategy addresses every aspect of corrosion prevention through scientifically proven product synergy.

Professional Application Advantages

While both products accommodate skilled DIY application, professional installation through certified technicians ensures optimal results through proper surface preparation, precise application techniques, and comprehensive coverage verification.

Professional facilities provide controlled environmental conditions, specialised spray equipment, and thorough surface preparation that maximises product performance and longevity.

Certified technicians understand the critical timing between ML and 4941 applications, ensuring proper adhesion and optimal protective film development.

Quality Assurance and Longevity

Both Dinitrol ML and 4941 represent premium-quality formulations backed by extensive testing and real-world performance validation. When applied correctly as part of a comprehensive system, these products deliver measurable rust prevention for years of reliable service.

The combination approach provides redundant protection: if mechanical damage compromises the 4941 barrier, the underlying ML treatment continues providing corrosion inhibition while the 4941's self-healing properties work to restore barrier integrity.

Making the Right Choice for Your Vehicle

Understanding the distinct roles of Dinitrol ML and 4941 enables informed decision-making about your vehicle's rust prevention requirements. Whether addressing a specific corrosion concern or implementing comprehensive preventive protection, selecting the appropriate product combination ensures optimal results.

For vehicles requiring maximum protection: particularly those exposed to harsh operating conditions or aggressive environmental factors: the combined ML and 4941 system provides unmatched corrosion resistance through scientifically proven product synergy.

Ready to protect your investment with premium Dinitrol products? Our certified technicians at Rustec specialise in professional-grade rust prevention using the complete range of Dinitrol formulations. Contact us today for expert consultation on the optimal protection strategy for your specific vehicle and operating conditions. We'll ensure your rust prevention investment delivers maximum protection and long-term value through proper product selection and professional application techniques.

Comments