What's the difference between rustproofing and undersealing?

- Lloyd Saunders

- Nov 8, 2025

- 4 min read

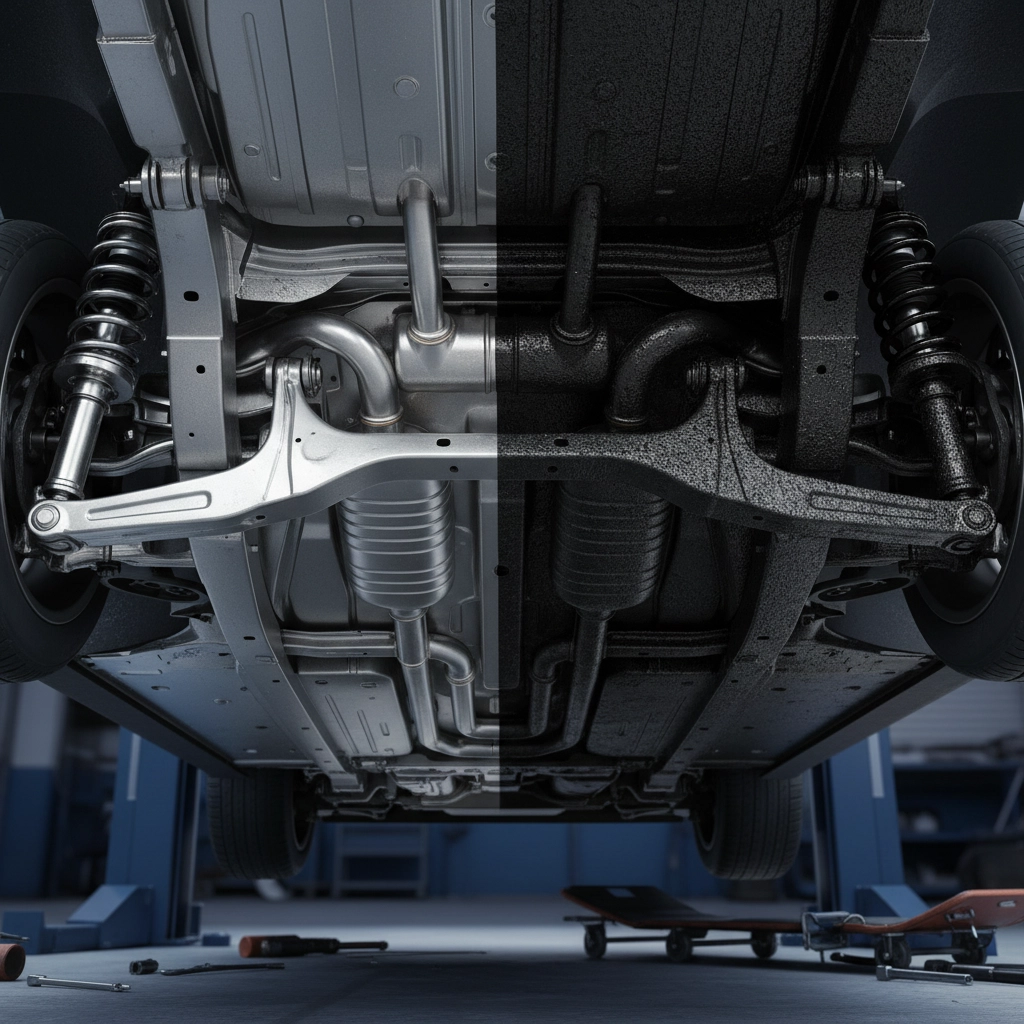

When researching vehicle protection services, many car owners encounter the terms "rustproofing" and "undersealing" and wonder whether they're the same thing. While both treatments prevent corrosion and extend your vehicle's lifespan, they target different areas of your car and use distinct application methods. Understanding these differences is crucial for making an informed decision about your vehicle's long-term protection.

Defining Rustproofing and Undersealing

Undersealing (also called undercoating) involves applying a protective coating to the entire underside of your vehicle, including the chassis, floorboards, wheel wells, and frame components. This comprehensive treatment creates a barrier between your vehicle's undercarriage and the harsh elements encountered on UK roads.

Rustproofing, by contrast, focuses on treating specific hard-to-reach areas throughout your vehicle where rust is most likely to develop. These include door frames, sills, wheel arches, tailgates, bonnets, and other cavity areas where moisture can accumulate and cause corrosion from the inside out.

Primary Areas of Protection

The fundamental difference lies in coverage areas. Undersealing provides blanket protection for everything visible beneath your vehicle - essentially creating a protective shield across the entire undercarriage. This treatment is particularly effective against road debris, salt spray, mud, and moisture that gets kicked up during driving.

Rustproofing takes a more targeted approach, addressing the hidden cavities and vulnerable spots where rust typically begins. These areas are often inaccessible during regular maintenance and cleaning, making them prime locations for corrosion to take hold unnoticed.

Application Methods and Materials

Undersealing Applications:

Tar-based or rubber-based compounds sprayed across the undercarriage

Wax-based treatments for comprehensive coverage

Applied externally to visible undercarriage components

Creates a thick, durable barrier against environmental elements

Rustproofing Applications:

Thin, penetrating oils and waxes injected into cavities

Protective treatments applied through existing drainage holes

Specialised equipment needed to reach internal spaces

Focus on displacing existing moisture while providing long-term protection

The application methods reflect their different purposes: undersealing requires coverage of large surface areas, while rustproofing demands precision to reach confined internal spaces.

When to Choose Undersealing

Undersealing proves most beneficial for vehicles regularly exposed to harsh driving conditions. Consider this treatment if your vehicle frequently encounters:

Heavy road salt during winter months

Off-road driving through mud, gravel, and debris

Coastal environments with salt air exposure

Commercial use with high mileage accumulation

Towing operations that stress undercarriage components

Undersealing Benefits:

Comprehensive undercarriage protection

Visible barrier against road debris impact

Easier to inspect and maintain

Immediate protection against environmental elements

Cost-effective for large surface area coverage

When to Choose Rustproofing

Rustproofing addresses the hidden corrosion that often causes the most expensive repair bills. This treatment becomes essential for:

Vehicles approaching or exceeding three years of age

Cars with known rust-prone designs or materials

Classic or heritage vehicles requiring long-term preservation

High-value vehicles where maintaining condition is paramount

Any vehicle showing early signs of cavity corrosion

Rustproofing Benefits:

Targets the most vulnerable corrosion areas

Penetrates existing rust to halt progression

Provides internal protection that external treatments cannot reach

Maintains structural integrity of critical components

Essential for comprehensive corrosion prevention

The Combined Approach: Maximum Protection

Leading automotive protection specialists, including Rustec, typically recommend combining both treatments for optimal results. This comprehensive approach addresses corrosion threats from multiple angles:

Complete Coverage: Undersealing protects visible surfaces while rustproofing safeguards hidden cavities Complementary Action: External barriers work alongside internal protection for comprehensive coverage Long-term Value: Combined treatments provide superior protection compared to either method alone Cost Efficiency: Addressing both areas simultaneously often proves more economical than separate treatments

Professional vs DIY Considerations

While some car owners attempt DIY applications, professional treatment offers significant advantages for both undersealing and rustproofing:

Professional Equipment:

Proper lifting facilities for complete undercarriage access

Specialised spray equipment for even application

Cavity injection tools for precision rustproofing

Steam cleaning capabilities for surface preparation

Expertise and Experience:

Knowledge of vehicle-specific vulnerable areas

Understanding of product compatibility and application techniques

Ability to identify existing corrosion and recommend appropriate treatments

Quality assurance through systematic application procedures

Product Quality:

Access to professional-grade treatments like Dinitrol systems

Products with proven track records in harsh UK conditions

Warranties and guarantees backing the application quality

Long-term performance superior to consumer-grade alternatives

Cost Considerations and Value

Investment in professional rustproofing and undersealing varies based on vehicle size, condition, and treatment scope. However, consider the long-term financial benefits:

Preservation of Vehicle Value: Rust-free vehicles maintain significantly higher resale values Reduced Repair Costs: Prevention costs far less than structural rust repairs or component replacement Extended Service Life: Protected vehicles often exceed their expected operational lifespan Peace of Mind: Comprehensive protection eliminates concerns about hidden corrosion development

Timing and Maintenance

Optimal Treatment Timing:

New vehicles: Within the first year for maximum protection

Used vehicles: Before visible rust appears, ideally during dry weather

Seasonal considerations: Spring or autumn applications allow proper curing time

Maintenance Requirements:

Annual inspections to assess treatment condition

Periodic top-up applications for high-wear areas

Documentation of treatment dates and products used

Integration with regular vehicle servicing schedules

Rustec's Professional Approach

At Rustec, we understand that effective corrosion protection requires both undersealing and rustproofing working in harmony. Our comprehensive treatment programmes combine these approaches using premium Dinitrol products specifically formulated for UK driving conditions.

Our systematic process includes:

Thorough undercarriage cleaning and preparation

Complete cavity injection rustproofing using specialised equipment

Professional-grade undersealing application where appropriate

Detailed documentation and treatment guarantees

Follow-up inspection services to ensure long-term effectiveness

We recognise that every vehicle has unique protection requirements based on age, usage patterns, and environmental exposure. Our experienced technicians assess each car individually to recommend the most appropriate combination of treatments for optimal protection and value.

Making the Right Choice for Your Vehicle

The question isn't whether to choose rustproofing or undersealing - it's understanding how both treatments work together to provide comprehensive protection. Modern vehicles face increasingly aggressive corrosion challenges from road treatments, environmental conditions, and intensive usage patterns.

Professional assessment helps determine the most appropriate treatment combination for your specific vehicle and circumstances. Factors including vehicle age, condition, intended usage, and budget all influence the optimal protection strategy.

Ready to protect your vehicle with professional rustproofing and undersealing services? Contact Rustec today for a comprehensive consultation and quote. Our expert team will assess your vehicle's specific requirements and recommend the most effective protection strategy to keep your car rust-free for years to come.

[Get your free consultation and quote today - contact Rustec at https://www.rustec.co.uk or call to discuss your vehicle's protection needs with our specialists.]

Comments