What's the best rustproofing for a daily driver?

- Lloyd Saunders

- 6 days ago

- 5 min read

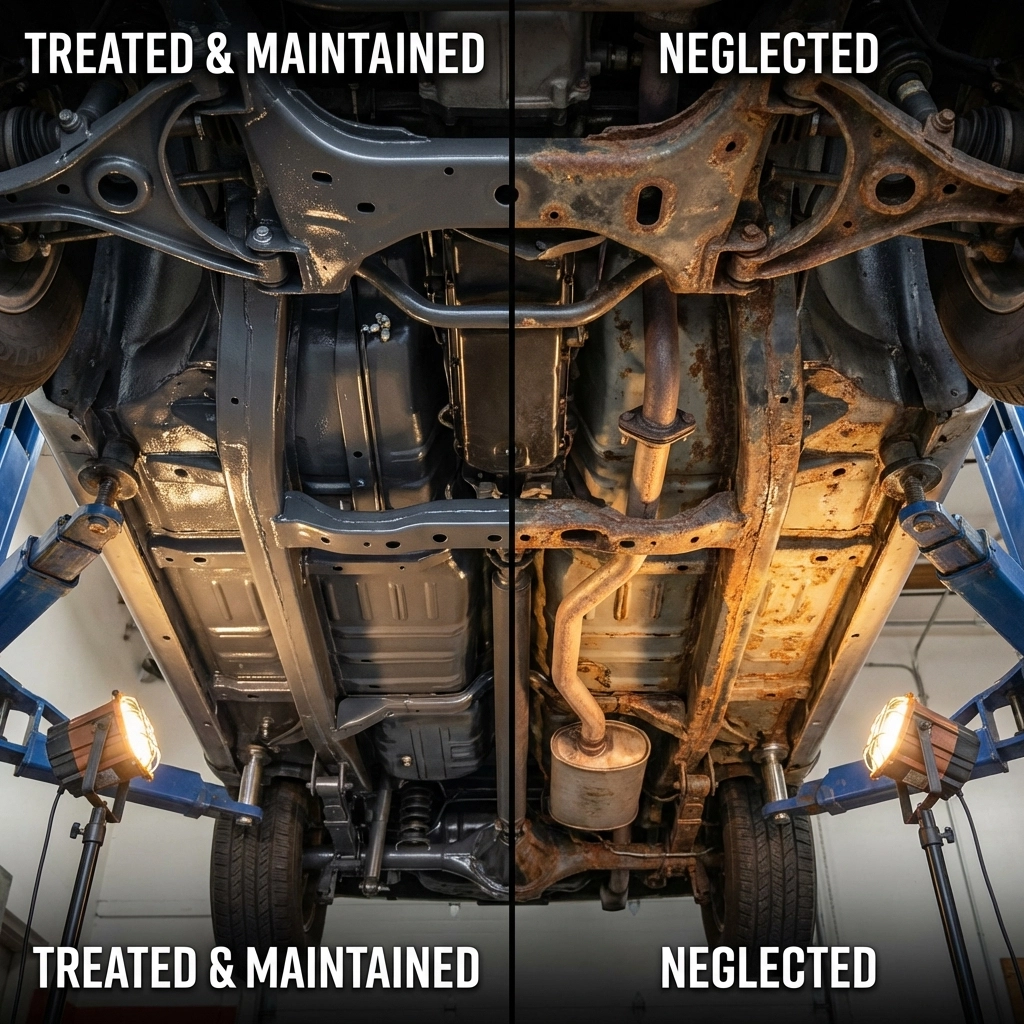

Your daily driver faces unique challenges that weekend vehicles simply don't encounter. From the relentless exposure to road salt during winter commutes to the constant moisture and debris kicked up from busy motorways, your everyday vehicle requires a rustproofing solution that can withstand the rigours of continuous use whilst maintaining optimal performance and longevity.

Understanding Daily Driver Requirements

Daily drivers demand a fundamentally different approach to rust protection compared to classic cars, weekend vehicles, or seasonal transport. These vehicles accumulate thousands of miles annually, experience frequent temperature fluctuations, and face continuous exposure to corrosive elements that accelerate rust formation.

The primary challenges facing daily drivers include:

Constant exposure to road salt, particularly during UK winter months

Regular contact with moisture from rain, puddles, and car washes

Temperature cycling from cold mornings to heated driving conditions

Debris impact from stones, grit, and road surface materials

Limited downtime for maintenance and reapplication procedures

These factors create an environment where rust can develop rapidly, making the choice of rustproofing system critical for long-term vehicle preservation. The ideal solution must provide comprehensive protection whilst remaining practical for ongoing maintenance schedules.

The Gold Standard: Drip Oil Spray Systems

For daily drivers, drip oil spray emerges as the most recommended rustproofing method amongst automotive protection specialists. This system delivers superior penetration capabilities, reaching into the smallest crevices and internal cavities where moisture typically accumulates and initiates corrosion processes.

Drip oil spray systems work by creating a migrating film that continuously spreads and self-heals minor damage. This characteristic proves invaluable for daily drivers that experience regular stone chips and surface abrasion. The oil-based formulation displaces moisture effectively whilst providing ongoing lubrication to moving components.

Key advantages of drip oil systems include:

Exceptional penetration into cavity areas and seam joints

Self-healing properties that maintain protection integrity

Compatibility with existing factory coatings and treatments

Long-lasting performance with proper application techniques

Cost-effective maintenance through annual reapplication

Wax-Based Systems: The Practical Choice

For vehicle owners seeking a balance between protection effectiveness and practical application, annual wax-based underseal combined with cavity wax represents the optimal approach. This methodology offers superior durability compared to traditional methods whilst maintaining ease of reapplication during routine maintenance intervals.

Wax-based systems provide several distinct advantages over older tar-based alternatives. The formulation remains flexible across temperature variations, preventing the cracking and separation issues commonly associated with brittle coatings. This flexibility proves essential for daily drivers experiencing constant thermal cycling.

Professional wax-based treatment typically includes:

Comprehensive chassis rail protection using specialised wax formulations

Targeted cavity wax application to door frames, sills, and internal seams

Wheel arch treatment to combat salt and debris accumulation

Floor pan sealing to prevent moisture penetration from road surfaces

The Layered Protection Strategy

The most effective rustproofing approach for daily drivers employs a comprehensive layered strategy that addresses different types of corrosion threats through multiple protective barriers. This methodology ensures optimal coverage across all vulnerable areas whilst providing redundancy should any single layer experience compromise.

The recommended layered approach follows this sequence:

Stage 1: Surface Preparation and Rust Conversion Begin with thorough surface preparation, including steam cleaning to remove existing contaminants. Apply rust converter to any areas showing early signs of corrosion, chemically neutralising active rust before applying protective coatings.

Stage 2: Primary Wax-Based Underseal Application Apply wax-based underbody seal to chassis rails, suspension mounting points, and floor pans. These areas receive the highest exposure to road salt and require robust protection against moisture infiltration.

Stage 3: Cavity Wax Treatment Utilise specialised cavity wax to penetrate doors, sills, box sections, and internal seams where moisture accumulates. This step proves critical for preventing hidden corrosion that often goes undetected until significant damage occurs.

Stage 4: Protective Film Application Complete the system with appropriate protective films or coatings that provide additional barrier protection whilst maintaining the underlying treatments.

Premium Product Selection for Daily Drivers

Professional-grade rustproofing requires carefully selected products that deliver consistent performance under demanding conditions. Trusted formulations for daily driver applications include Dinitrol cavity wax systems, Hammerite Underbody Seal, and Liqui Moly Bitumen Underbody Protection.

These products undergo rigorous testing to ensure compatibility with modern vehicle systems whilst delivering long-term protection effectiveness. The selection process considers factors including:

Chemical compatibility with existing factory coatings

Temperature stability across UK climate variations

Penetration capabilities for comprehensive coverage

Maintenance requirements and reapplication procedures

Environmental impact and safety considerations

Dinitrol systems particularly excel in cavity protection applications, offering superior penetration and displacement properties. The range includes specific formulations for different application areas, ensuring optimal protection characteristics for each vehicle component.

Professional Application vs DIY Considerations

Daily driver rustproofing presents unique challenges that often favour professional application over DIY approaches. The complexity of modern vehicle design, combined with the need for comprehensive coverage, makes professional treatment increasingly valuable for optimal results.

Professional application advantages include:

Access to commercial-grade equipment and products

Comprehensive vehicle preparation including steam cleaning

Expert knowledge of vehicle-specific vulnerable areas

Quality assurance through systematic application procedures

Warranty coverage and ongoing support services

However, motivated vehicle owners can achieve satisfactory results through careful DIY application, particularly for maintenance and touch-up procedures. Success requires proper equipment, quality products, and adherence to recommended application techniques.

Maintenance Requirements and Longevity

Daily driver rustproofing requires ongoing maintenance to ensure continued effectiveness. Annual inspections and touch-up applications prove essential for maintaining protection integrity, with specific frequency depending on operating conditions and climate exposure.

Vehicles operating in coastal environments or areas with intensive winter salt use benefit from reapplication every 2-3 years, whilst those in milder conditions may extend intervals accordingly. Regular inspection allows early identification of areas requiring attention before significant compromise occurs.

Effective maintenance programmes include:

Annual comprehensive undercarriage inspection

Touch-up application to high-wear areas

Cavity wax renewal in critical locations

Documentation of treatment dates and products used

Professional assessment of overall system condition

Climate-Specific Considerations

UK driving conditions present particular challenges for rustproofing systems, with regional variations requiring tailored approaches. Coastal areas experience accelerated corrosion due to salt air exposure, whilst northern regions face extended winter salt seasons that increase protection demands.

Daily drivers in these challenging environments benefit from enhanced protection protocols, including:

Increased application frequency in critical areas

Selection of products specifically formulated for marine or winter conditions

Additional cavity protection in vulnerable locations

Regular professional inspection and maintenance services

Investment Value and Long-Term Benefits

Professional rustproofing represents a significant investment in vehicle longevity and resale value preservation. Quality protection systems typically cost between £300-£800 depending on vehicle size and treatment complexity, delivering substantial returns through extended vehicle life and maintained market value.

The investment becomes particularly attractive when considering the alternative costs of rust repair, which can easily exceed several thousand pounds for comprehensive chassis restoration. Prevention through proper rustproofing proves far more cost-effective than remedial treatment after corrosion establishes.

Making the Right Choice

Selecting optimal rustproofing for your daily driver requires careful consideration of your specific requirements, operating conditions, and maintenance preferences. Professional consultation ensures appropriate product selection and application techniques for your particular circumstances.

At Rustec, our comprehensive rustproofing services employ premium Dinitrol systems and professional application techniques to deliver exceptional protection for daily drivers. Our experienced technicians understand the unique challenges facing everyday vehicles and provide tailored solutions that deliver long-lasting results.

Contact our specialist team to discuss your daily driver rustproofing requirements and discover how professional protection can preserve your investment for years to come. With locations across the UK and comprehensive warranty coverage, we provide the expertise and assurance you need for complete peace of mind.

Your daily driver deserves the highest standard of protection – ensure it receives the comprehensive rustproofing treatment that will keep it performing reliably mile after mile, year after year.

Comments