Should I rustproof a company fleet vehicle?

- Lloyd Saunders

- Dec 16, 2025

- 4 min read

When managing a company fleet, every decision impacts your bottom line. One crucial consideration that many fleet managers overlook is rustproofing - a preventive measure that can deliver substantial returns on investment while maintaining operational efficiency.

The answer is unequivocally yes: rustproofing your company fleet vehicles is not just recommended, it's a strategic business decision that pays dividends across multiple areas of fleet management.

The Financial Case for Fleet Rustproofing

Long-Term Cost Savings

Rustproofing delivers immediate and long-term financial benefits that directly impact your operational budget. By preventing rust and corrosion, you extend the functional lifespan of your fleet vehicles significantly. This means avoiding the substantial capital expense of premature vehicle replacement - a cost that can run into tens of thousands of pounds per vehicle.

The mathematics are compelling: a comprehensive rustproofing treatment typically costs between £400-£800 per vehicle, while early replacement due to corrosion damage can cost £15,000-£50,000+ depending on your fleet composition. The investment pays for itself many times over through extended vehicle life.

Enhanced Resale Value

Fleet vehicles with comprehensive rust protection command significantly higher resale values when it's time to refresh your fleet. Clean, corrosion-free vehicles present better to potential buyers and demonstrate that your company maintains its assets professionally. This reputation for quality maintenance can translate into better trade-in values and faster sales processes.

Reduced Maintenance and Downtime Costs

Rust-related repairs are among the most expensive and time-consuming maintenance issues fleet managers face. By preventing corrosion from taking hold, rustproofing eliminates costly structural repairs, panel replacements, and chassis restoration work. More importantly, it prevents unexpected breakdowns that can sideline vehicles and disrupt operations.

Operational Advantages for Fleet Management

Improved Vehicle Reliability

A properly rustproofed fleet maintains consistent operational reliability. Corrosion compromises critical vehicle systems - from brake lines to suspension components - creating safety risks and unexpected failures. Professional rustproofing creates a barrier that keeps these systems functioning optimally throughout the vehicle's service life.

Reduced Administrative Burden

Managing a fleet plagued by rust issues creates significant administrative overhead. Scheduling repairs, arranging replacement vehicles, managing insurance claims, and coordinating with maintenance providers consumes valuable management time. Rustproofing eliminates much of this administrative burden by preventing problems before they occur.

Compliance and Safety Benefits

Fleet vehicles must pass regular MOT inspections, and rust-related failures are increasingly common as vehicles age. Structural corrosion can render a vehicle unroadworthy, creating compliance issues and potential liability concerns. Rustproofing ensures your fleet maintains the structural integrity required for safe operation and regulatory compliance.

Professional Image and Brand Representation

Your fleet vehicles serve as mobile advertisements for your business. Clean, well-maintained vehicles in good condition project professionalism and success to customers, suppliers, and competitors. Visible rust, corroded panels, and deteriorating underbody components send the opposite message - suggesting poor management and lack of attention to detail.

This perception matters significantly in competitive markets where professional image influences customer decisions. A rustproofed fleet maintains its appearance longer, requiring fewer cosmetic repairs and presenting consistently well throughout its service life.

Environmental Considerations

Modern rustproofing treatments align with corporate sustainability goals. Quality rustproofing products are environmentally responsible, containing no toxic chemicals while significantly extending vehicle lifecycles. This reduces the environmental impact of premature vehicle disposal and the energy-intensive manufacturing processes required for replacement vehicles.

Extended vehicle life directly supports circular economy principles by maximising asset utilisation before disposal. For companies with environmental commitments or sustainability reporting requirements, fleet rustproofing represents a measurable contribution to these objectives.

When Fleet Rustproofing is Essential

Harsh Operating Environments

Fleet vehicles operating in challenging conditions require additional protection. Coastal areas with salt-laden air, regions using winter road salt, and environments with high humidity or industrial pollution accelerate corrosion processes. In these conditions, rustproofing transitions from beneficial to essential for maintaining fleet integrity.

Commercial Vehicle Applications

Vans, trucks, and specialist commercial vehicles face particular corrosion challenges. Their design often includes numerous joints, seams, and mounting points where moisture can accumulate. The loading and unloading processes can damage protective coatings, creating entry points for corrosion. Professional rustproofing addresses these vulnerabilities comprehensively.

Mixed-Use Fleet Considerations

Fleet vehicles serving multiple purposes - from urban delivery to rural operations - encounter varied corrosion threats. This exposure diversity makes comprehensive protection essential, as vehicles may face road salt one day and coastal air the next.

Implementation Strategy for Fleet Rustproofing

Timing Considerations

New vehicle rustproofing delivers optimal results, as treatments can be applied to clean, corrosion-free surfaces. However, vehicles with existing minor surface rust can still benefit significantly from professional treatment that arrests further deterioration.

The ideal timing involves treating vehicles during their first winter preparation, before road salt exposure begins. This proactive approach ensures maximum protection during the most challenging corrosion season.

Treatment Selection

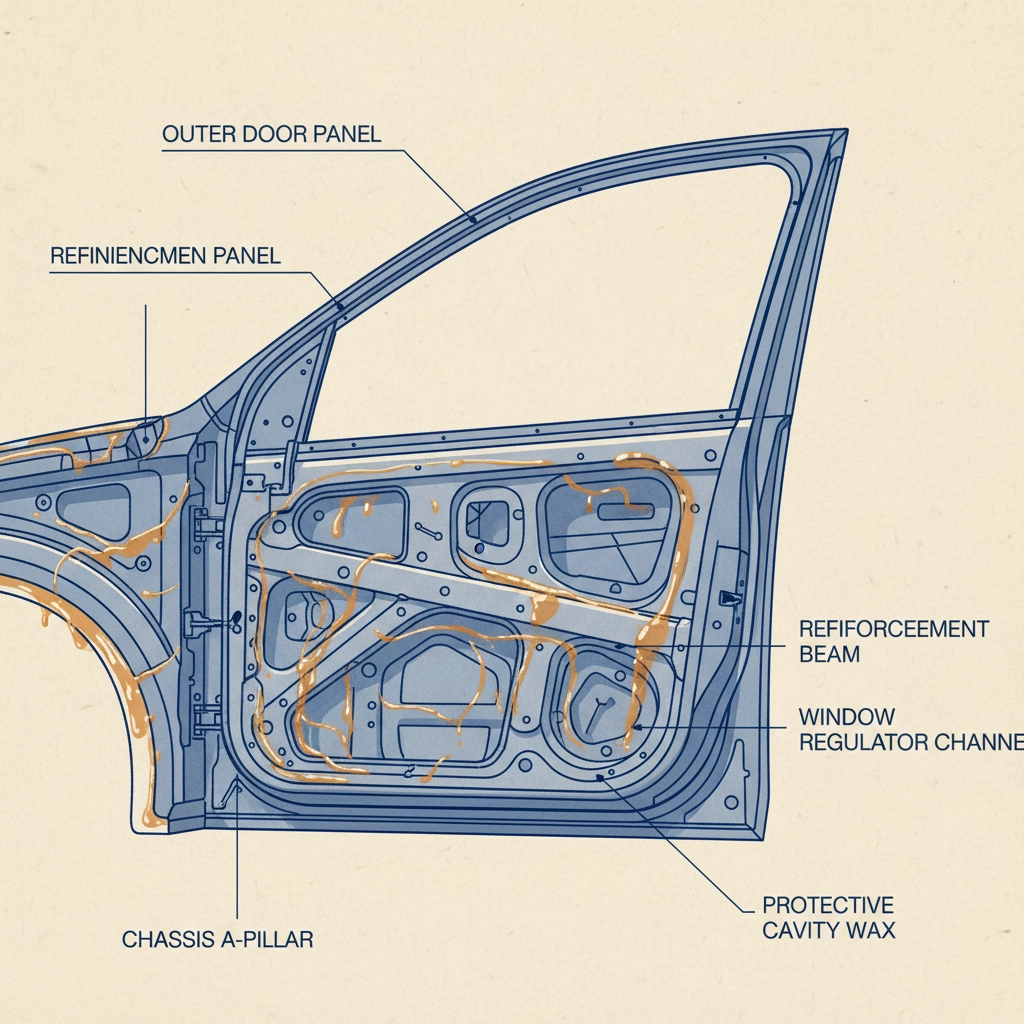

Professional fleet rustproofing typically involves multiple products targeting specific areas:

Cavity wax for internal protection of box sections and door frames

Underseal for chassis and underbody protection

Penetrating treatments for existing corrosion arrest

Quality treatments like Dinitrol provide comprehensive protection with extended warranties, offering additional peace of mind for fleet investments.

Return on Investment Analysis

Fleet rustproofing delivers measurable returns across multiple metrics:

Direct Cost Savings: Reduced repair bills, extended vehicle life, improved resale values Operational Benefits: Decreased downtime, improved reliability, reduced administrative burden Risk Mitigation: Enhanced safety, compliance assurance, liability reduction

Most fleet managers report that rustproofing investments pay for themselves within 18-24 months through reduced maintenance costs alone, with additional benefits continuing throughout the vehicle's extended service life.

Making the Decision

For fleet managers evaluating rustproofing, the question isn't whether vehicles need protection - it's whether you can afford not to protect them. The combination of financial benefits, operational advantages, and risk mitigation makes rustproofing one of the most cost-effective maintenance investments available.

Professional rustproofing transforms vehicle maintenance from reactive crisis management to proactive asset protection. This shift reduces costs, improves operational efficiency, and supports long-term fleet planning objectives.

The evidence is clear: rustproofing company fleet vehicles delivers substantial returns on investment while supporting professional image, operational reliability, and environmental responsibility. For fleet managers committed to optimising total cost of ownership while maintaining operational excellence, rustproofing isn't optional - it's essential.

Contact us today to discuss comprehensive rustproofing solutions tailored to your fleet requirements and operating environment.

Comments