Should I rustproof a brand-new car?

- Lloyd Saunders

- Nov 3, 2025

- 5 min read

The short answer is yes – and here's why your shiny new vehicle needs professional protection from day one.

Many new car owners fall into the dangerous trap of believing their vehicle is completely protected against rust simply because it's fresh from the factory. This costly misconception leaves thousands of UK drivers facing premature corrosion, failed MOTs, and devastating repair bills just a few years down the road.

While modern vehicles do come with factory-applied galvanising and protective coatings, these baseline measures are nowhere near sufficient for the harsh realities of UK road conditions. Professional rustproofing isn't just recommended for new cars – it's essential for maintaining your vehicle's structural integrity, safety, and resale value.

Why Factory Protection Falls Short in UK Conditions

Manufacturers design their standard rust protection for global markets and average conditions – not the aggressive combination of road salt, coastal air, persistent rainfall, and temperature fluctuations that define the UK climate. Your new car's factory coating is a starting point, not a complete solution.

The galvanising process covers major steel components, but it cannot protect every vulnerable area of your vehicle's complex undercarriage. Welded joints, overlapping panels, and cavity spaces remain exposed to moisture penetration – creating the perfect environment for rust to take hold and spread rapidly.

Factory underseal, where applied, is typically a thin, basic coating designed more for noise reduction than comprehensive corrosion protection. It lacks the penetrating properties and long-term durability needed to withstand years of UK winter conditions and road salt exposure.

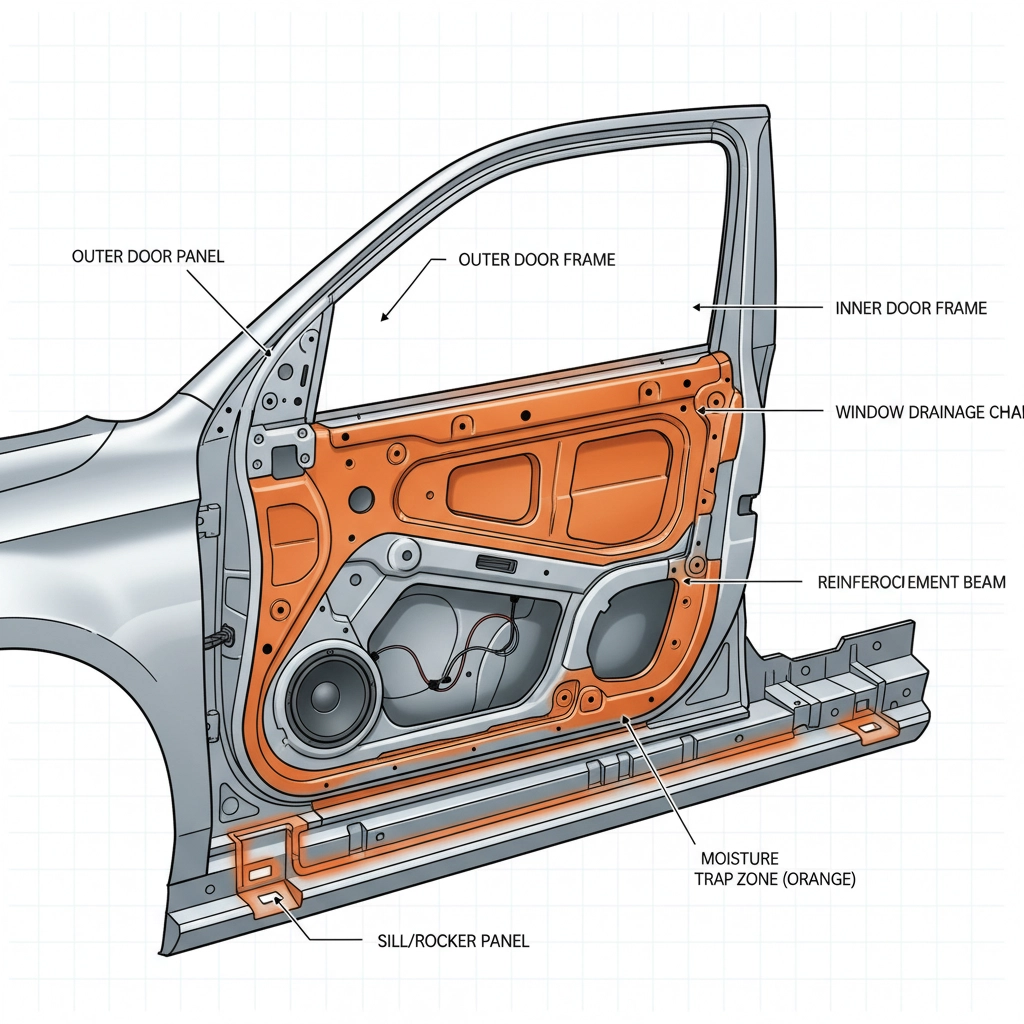

Hidden Vulnerabilities in Your Brand-New Vehicle

Even with pristine paintwork and showroom condition, your new car harbours multiple rust entry points that become active the moment you drive off the forecourt:

Chassis rails and crossmembers feature complex internal geometries where moisture can accumulate without natural drainage points. These areas are impossible to adequately protect during factory assembly.

Door frames, sills, and pillars contain cavity spaces that trap condensation and road spray. Without proper cavity wax treatment, these areas begin corroding from the inside out – often undetected until serious structural damage has occurred.

Suspension mounting points and subframe connections endure constant stress and movement, causing protective coatings to crack and peel, exposing bare metal to aggressive UK road conditions.

Stone chip damage from everyday driving immediately compromises paint protection, creating microscopic entry points where rust can establish and spread beneath seemingly intact surfaces.

The Strategic Advantage of Early Professional Treatment

Rustproofing your vehicle while it's brand new provides maximum protection effectiveness and cost efficiency. Starting with clean, rust-free surfaces allows professional treatments to form optimal bonds and create comprehensive barrier protection.

Complete surface preparation is straightforward on new vehicles – no time-consuming rust removal, grinding, or repair work required. This means more budget allocated to premium protection products rather than corrective treatments.

Preventive treatment penetrates fully into all cavity spaces and vulnerable areas before any corrosion begins. Once rust takes hold, even professional treatments cannot achieve the same level of comprehensive protection.

Warranty compatibility is maintained when professional rustproofing is applied correctly to new vehicles. Many manufacturers explicitly allow aftermarket protection provided it meets industry standards and doesn't interfere with original components.

UK-Specific Corrosion Challenges Your New Car Will Face

The combination of factors that make UK roads particularly aggressive to vehicle undercarriages creates an environment where factory protection alone is insufficient:

Winter road salt contains chloride compounds specifically chosen for their ice-melting effectiveness – the same properties that accelerate metal corrosion. Modern de-icing treatments are more concentrated and persistent than ever before.

Coastal proximity means even inland areas experience salt-laden air that settles on vehicle surfaces. The UK's geography ensures few areas escape this atmospheric corrosion factor entirely.

Temperature cycling between freezing and thawing throughout winter causes protective coatings to expand and contract repeatedly, creating stress fractures that allow moisture penetration.

Persistent moisture from frequent rainfall and high humidity levels means your vehicle's undercarriage rarely gets opportunity to fully dry out – maintaining ideal conditions for rust development year-round.

Pothole damage and debris impact from deteriorating road surfaces causes ongoing mechanical damage to underseal and protective coatings, requiring regular maintenance and reapplication.

Professional Treatment Delivers Comprehensive Protection

Life Long Dinitrol® treatments represent the gold standard in new vehicle protection, offering superior coverage and longevity compared to basic factory applications. Our comprehensive approach addresses every vulnerable area through systematic application of multiple product formulations:

Cavity wax injection reaches internal spaces that factory treatments cannot access, providing long-term protection where rust typically begins. Dinitrol ML penetrates and displaces moisture while forming flexible protective films.

Underbody coating application creates durable barrier protection against stone chip damage, salt spray, and road debris impact. Unlike thin factory underseals, professional treatments build substantial protective thickness.

Joint sealing and vulnerable area treatment ensures welded connections, panel overlaps, and stress points receive specialized attention with appropriate product formulations for each specific application.

Quality assurance through photo documentation provides you with complete records of treatment coverage and baseline condition – essential for warranty claims and insurance purposes.

Timing Is Critical for Maximum Effectiveness

The window for optimal rustproofing results closes rapidly once corrosion begins. Even minor surface rust compromises treatment adhesion and long-term effectiveness, making immediate action essential for new vehicle owners.

First winter exposure without professional protection allows road salt to establish corrosion patterns that become increasingly difficult and expensive to address. Prevention costs a fraction of remedial treatment or structural repairs.

Cavity protection must be completed before moisture intrusion begins internal corrosion processes. Once rust starts inside panel spaces, even professional treatment cannot fully restore protection levels.

Optimal weather conditions for treatment application occur during warmer, drier months when products cure properly and achieve maximum effectiveness. Delaying beyond your first autumn reduces treatment performance.

Why Professional Application Outperforms DIY Attempts

Effective rustproofing requires specialized equipment, industry knowledge, and premium products that amateur treatments cannot match. Professional application ensures comprehensive coverage and optimal product performance:

Pressure spray equipment delivers uniform coating thickness and penetrates complex geometries that brush or aerosol application cannot reach effectively.

Product selection expertise matches appropriate formulations to specific applications – cavity waxes, barrier coatings, and flexible sealers each serve distinct protective functions.

Surface preparation standards ensure optimal adhesion and treatment longevity through proper cleaning, degreasing, and masking procedures that maintain manufacturer warranty compliance.

Comprehensive coverage verification through systematic inspection and documentation prevents missed areas that compromise overall protection effectiveness.

Protect Your Investment with Professional Rustproofing

Your new vehicle represents a significant investment that deserves premium protection from the UK's aggressive road environment. Factory rust protection provides a foundation, but professional treatment is essential for comprehensive, long-term corrosion prevention.

At Rustec, we specialise in Life Long Dinitrol® treatments that keep your pride and joy rust-free throughout its entire service life. Our meticulous application process, premium products, and comprehensive warranty coverage provide the ultimate peace of mind for discerning vehicle owners.

Don't wait until rust becomes visible – by then, the damage is already extensive and expensive to address properly. Book your professional rustproofing treatment today and ensure your new vehicle maintains its structural integrity, safety, and value for years to come.

Contact Rustec now to schedule your comprehensive new vehicle protection treatment. Our expert team will provide detailed consultation and competitive quotation for the premium rustproofing solution your investment deserves.

Comments