Rust inside wheel arches – what to look for

- Lloyd Saunders

- Nov 15, 2025

- 5 min read

Wheel arches represent one of the most vulnerable areas on any vehicle when it comes to rust formation. These critical junction points where your vehicle's suspension meets the bodywork create the perfect storm of conditions for corrosion to take hold and spread rapidly if left unchecked.

Understanding what to look for and when to take action can mean the difference between a simple preventative treatment and expensive structural repairs. The key lies in recognising the early warning signs before they develop into serious problems that could compromise your vehicle's safety and MOT compliance.

Early Warning Signs of Wheel Arch Rust

Bubbling or blistering paint often provides the first indication that rust has begun forming beneath the surface. This occurs when moisture penetrates microscopic gaps in the paintwork and begins oxidising the metal underneath. The expanding rust literally pushes the paint outward, creating distinctive bubble formations that feel soft to the touch.

These bubbles typically appear along the wheel arch lip where the outer panel meets the inner wheelhouse, or around the edges where debris impact has compromised the protective coating. Even small bubbles no larger than a pinhead should be treated seriously, as they indicate active corrosion beneath.

Small rust flakes and discoloured spots represent the next stage of deterioration. These appear as tiny brown or orange particles that can be scraped away with a fingernail, often accompanied by dull or discoloured patches where the paint has lost its original lustre. The affected areas may feel slightly rough or textured compared to surrounding paintwork.

Paint chips and clearcoat damage create direct pathways for moisture and road salt to reach bare metal. Any area where the protective paint layer has been compromised becomes a potential rust initiation point. Look particularly carefully at the wheel arch lip and any raised edges where stone chips are most likely to occur.

Why Wheel Arches Are Particularly Susceptible

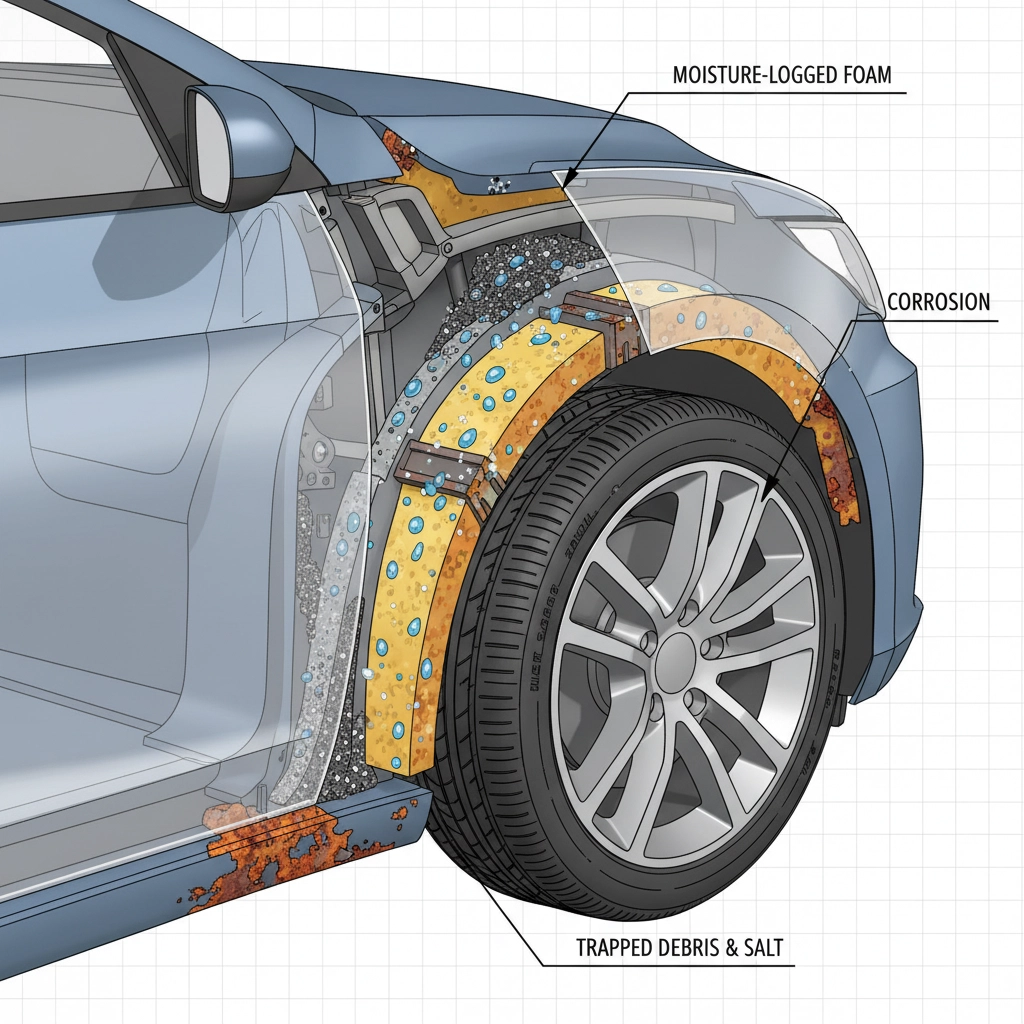

The design of modern wheel arches creates an environment where rust can thrive unchecked. The cavity between the inner wheelhouse and outer arch panel forms a natural collection point for road salt, mud, and moisture. Unlike other areas of the vehicle that benefit from regular washing and air circulation, these hidden spaces often remain damp for extended periods.

Foam insulation compounds the problem. Many modern vehicles include sound-deadening foam inside the wheel arch cavity. While effective at reducing road noise, this foam acts like a sponge, absorbing moisture from road spray and condensation. Once saturated, the foam maintains contact with bare metal surfaces, creating ideal conditions for rust to develop from the inside out.

Water penetration through panel gaps represents another major vulnerability. The junction between inner and outer wheel arch panels relies on sealant to prevent moisture ingress. Over time, vibration and temperature changes cause this sealant to deteriorate, allowing water and salt to penetrate directly to vulnerable steel surfaces.

Limited drainage means that any moisture entering the wheel arch cavity has few escape routes. Blocked drain holes or inadequate drainage design can trap contaminated water in contact with metal surfaces for weeks or months, particularly during winter conditions.

Proper Inspection Technique

Start with a visual inspection of the external wheel arch area. Work systematically around each arch, looking for any paint defects, rust staining, or colour changes. Pay particular attention to the lower edge where the arch meets the sill, as this area frequently shows the first signs of problems.

Use a torch or inspection light to examine the inner wheelhouse areas visible when turning the steering to full lock. Look for rust staining, flaking metal, or areas where the protective coating appears damaged or missing.

Physical inspection involves carefully probing any suspicious areas with a blunt instrument. Seriously corroded areas may feel soft or spongy, while surface rust typically feels rough or granular. Any area that yields to gentle pressure indicates structural deterioration requiring immediate attention.

Check for rust staining patterns that indicate water flow paths. Vertical rust streaks often show where water runs off contaminated surfaces, while horizontal staining may indicate areas where moisture collects and pools.

Prevention Strategies

Regular washing of the wheel arch areas helps remove accumulated salt and debris before it can cause damage. Use a stiff brush to scrub inside the wheel arch cavity, paying particular attention to areas around the suspension mounting points and any visible seams or joints.

Seasonal treatments with appropriate protective products can significantly extend wheel arch life. Quality cavity waxes and rust preventatives create a barrier against moisture penetration while displacing any existing water from vulnerable areas.

Prompt repair of any paint damage prevents small problems from developing into major structural issues. Stone chips and minor scratches should be touched up immediately using appropriate primer and paint systems.

Drain hole maintenance ensures that any water entering the wheel arch cavity can escape freely. These small holes, typically located at the lowest point of each arch, can become blocked with debris and require periodic cleaning.

Professional Assessment Benefits

While basic visual inspection can identify obvious problems, professional assessment using specialist equipment provides a more comprehensive evaluation of wheel arch condition. Professional technicians use endoscopes and digital inspection cameras to examine hidden areas that remain invisible during standard checks.

Comprehensive treatment planning ensures that any issues identified receive appropriate attention using the correct products and application methods. Professional services typically include thorough preparation, appropriate product selection, and proper curing procedures that maximise treatment effectiveness.

Documentation and warranties provide peace of mind and demonstrate due diligence for insurance and resale purposes. Professional treatments typically include photographic evidence of pre-treatment condition and comprehensive warranties covering both materials and workmanship.

When Professional Intervention Becomes Essential

Surface rust and minor paint defects can often be addressed through DIY methods, but certain conditions require professional attention. Structural rust affecting load-bearing areas or safety-critical components demands immediate expert evaluation and appropriate repair procedures.

Extensive corrosion involving multiple areas or complex geometries typically requires specialist tools and techniques beyond the scope of DIY treatments. Professional services can access restricted areas using specialised application equipment and provide comprehensive coverage that ensures long-term effectiveness.

MOT implications make professional assessment particularly valuable. Rust affecting structural integrity or safety systems can result in MOT failure, potentially requiring expensive remedial work. Early professional intervention often prevents minor issues from developing into test failures.

Your vehicle deserves comprehensive protection against the relentless threat of wheel arch corrosion. At Rustec, our specialist technicians provide thorough wheel arch inspection and treatment services using premium Dinitrol products and proven application techniques.

Our comprehensive inspection process identifies potential problems before they become serious issues, while our lifetime treatment options provide long-term protection and peace of mind. Contact us today to arrange a professional wheel arch assessment and discover how our expert services can protect your investment for years to come.

Book your professional wheel arch inspection and benefit from our comprehensive evaluation process, detailed photographic documentation, and industry-leading treatment warranties.

Comments