Lanoguard vs grease-based underseal

- Lloyd Saunders

- Dec 19, 2025

- 4 min read

When choosing underbody protection for your vehicle, the decision between Lanoguard and traditional grease-based underseals represents a choice between modern innovation and established protection methods. Each approach offers distinct advantages, and understanding these differences is crucial for making an informed decision that will protect your investment for years to come.

Understanding the Two Approaches

Lanoguard: The Modern Solution

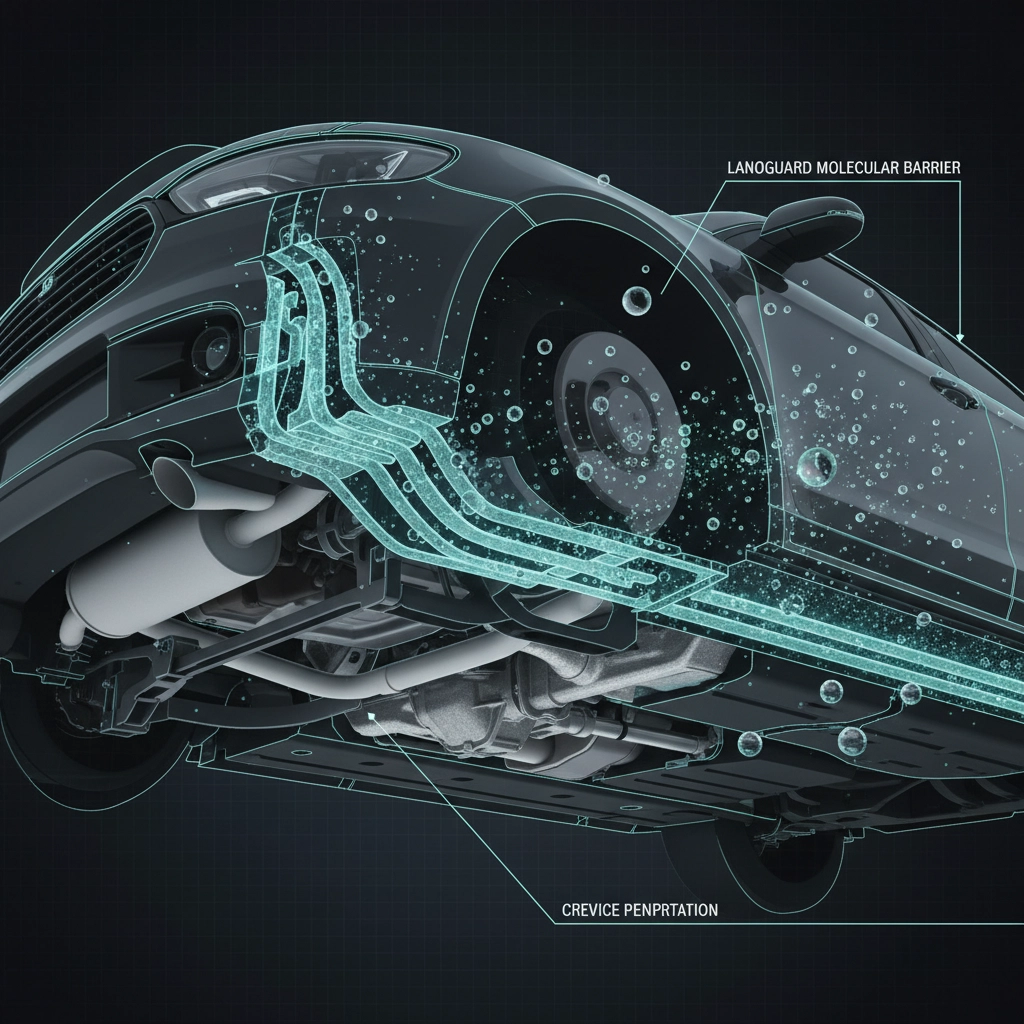

Lanoguard represents a revolutionary approach to underbody protection, utilising lanolin-based technology that transforms traditional thinking about rust prevention. This innovative system combines a liquid spray component with a specialised grease, creating comprehensive protection that adapts to your vehicle's specific needs.

The liquid spray applies as a fine mist that penetrates into the smallest crevices, whilst the grease component targets critical areas such as seams, nuts, bolts, sharp edges, and threads. This dual-system approach ensures every vulnerable area receives appropriate protection tailored to its exposure level.

Grease-Based Underseals: The Traditional Standard

Traditional grease-based underseals, exemplified by products like Waxoyl, have provided reliable underbody protection for decades. These products feature a thick, viscous consistency that creates a substantial physical barrier between your vehicle's metal components and the harsh elements of British roads.

Comprehensive Performance Comparison

Feature | Lanoguard | Grease-Based Underseals |

Application Time | 15-30 minutes | 2-4 hours |

Surface Preparation | Basic wash and wire brushing | Extensive rust removal required |

Rust Compatibility | Can be applied over stable rust | Requires bare metal for optimal adhesion |

Finish Appearance | Clear, wax-like coating | Thick, dark protective layer |

Heat Resistance | Stable to 450°F without evaporation | Variable heat tolerance |

Maintenance | Annual coat-on-coat top-ups | Complete reapplication often required |

Environmental Impact | Non-toxic, eco-friendly formulation | Petroleum-based chemistry |

Component Lubrication | Active lubrication of bushings and joints | Limited lubrication properties |

Application Excellence and Efficiency

The application process reveals significant differences between these protection methods. Lanoguard's innovative formulation eliminates the need for extensive masking, allowing application without concern for overspray on surrounding components. This efficiency translates to reduced labour costs and faster turnaround times whilst maintaining comprehensive protection standards.

Traditional grease-based underseals demand meticulous preparation and careful application to avoid thick accumulations that can trap moisture rather than repel it. The viscous nature of these products requires specific application techniques and often multiple coats to achieve uniform coverage.

Advanced Protection Characteristics

Moisture Management Technology

Lanoguard's self-healing properties continuously work to maintain protective integrity. The formulation actively draws moisture and salt deposits away from metal surfaces during the curing process, creating a dynamic barrier that responds to environmental challenges. This active protection mechanism ensures long-term effectiveness even in the harshest British weather conditions.

Penetration and Coverage

The lanolin-based formulation demonstrates exceptional penetrative capabilities, creeping into areas that traditional thick underseals cannot reach. This comprehensive coverage addresses vulnerable spots that often become rust initiation points, providing protection where it's needed most.

Long-Term Value Assessment

Maintenance Requirements

Lanoguard's clear finish provides a significant diagnostic advantage, allowing visual inspection of the underlying metal condition without removal of the protective coating. This transparency enables proactive maintenance decisions and early intervention before serious corrosion develops.

The annual top-up process requires minimal effort, with new product bonding directly to the existing coating without removal or extensive preparation. This coat-on-coat compatibility reduces long-term maintenance costs whilst maintaining optimal protection levels.

Durability Considerations

Traditional grease-based underseals offer the reassurance of established performance records spanning decades of use. However, their static nature means protection quality depends entirely on initial application thoroughness and may require complete reapplication when maintenance becomes necessary.

Professional Application Standards

Quality Control Benefits

Professional application of Lanoguard allows technicians to complete thorough treatments efficiently whilst maintaining exacting standards. The reduced complexity of application means more time can be dedicated to comprehensive coverage rather than extensive preparation procedures.

Equipment Requirements

Lanoguard application requires standard spray equipment without specialised heating or mixing systems. This simplicity ensures consistent application quality whilst reducing the potential for application errors that can compromise protection effectiveness.

Environmental and Safety Considerations

Eco-Friendly Formulation

Lanoguard's non-toxic, biodegradable formulation aligns with modern environmental standards whilst maintaining superior protective performance. The absence of harmful petroleum-based solvents makes it safe for technicians and environmentally responsible.

Workshop Safety

The reduced toxicity and pleasant application characteristics of Lanoguard create a safer working environment compared to traditional petroleum-based underseals that may require extensive ventilation and safety measures.

Vehicle-Specific Applications

Modern Vehicle Compatibility

Contemporary vehicles with complex underbody components, sensors, and electronic systems benefit from Lanoguard's precision application capabilities. The clear finish allows continued monitoring of critical components whilst providing comprehensive protection.

Classic and Commercial Vehicles

Traditional grease-based underseals may suit applications where maximum coating thickness is prioritised over application convenience, particularly on older vehicles with simpler underbody configurations or commercial applications requiring maximum durability.

Cost-Effectiveness Analysis

Initial Investment Considerations

Whilst Lanoguard may represent a higher initial material cost, the reduced application time and minimal preparation requirements often result in comparable total treatment costs. The superior longevity and easier maintenance typically provide better long-term value.

Long-Term Economic Benefits

The annual maintenance capability of Lanoguard eliminates the need for complete reapplication, distributing protection costs over time rather than requiring substantial reinvestment every few years.

Professional Recommendations

Optimal Choice Criteria

For vehicles requiring efficient, comprehensive protection with minimal ongoing maintenance, Lanoguard represents the superior choice. The combination of easier application, better penetration, and superior maintenance characteristics makes it particularly suitable for modern vehicles and busy lifestyles.

Traditional grease-based underseals remain viable for specific applications where maximum coating thickness is prioritised and regular maintenance schedules accommodate more intensive reapplication requirements.

Expert Guidance

At Rustec, our extensive experience with both protection systems enables us to recommend the optimal solution based on your vehicle's specific requirements, usage patterns, and maintenance preferences. Our comprehensive assessment ensures you receive protection that delivers maximum value whilst meeting your individual needs.

The choice between Lanoguard and grease-based underseals ultimately depends on balancing application convenience, long-term maintenance requirements, and specific vehicle protection needs. Professional consultation ensures optimal protection selection that maintains your vehicle's condition for years to come.

Comments