How to spot hidden rust on a 4x4 or van

- Lloyd Saunders

- Nov 30, 2025

- 6 min read

When it comes to 4x4s and vans, hidden rust represents one of the most serious threats to your vehicle's structural integrity and safety. Unlike surface rust that's immediately visible, hidden corrosion develops silently within enclosed frame cavities, beneath protective coatings, and in areas where moisture and debris accumulate over time. For commercial van operators and off-road enthusiasts, understanding how to identify these concealed problem areas is essential for maintaining vehicle safety and avoiding costly structural repairs down the line.

The challenge with hidden rust lies precisely in its concealed nature – by the time it becomes visible from the outside, significant structural damage may have already occurred. This comprehensive inspection guide will equip you with the knowledge and techniques needed to detect rust before it compromises your vehicle's safety or fails an MOT inspection.

Essential Tools for Professional-Grade Rust Detection

Conducting a thorough rust inspection requires the right equipment to access and examine hard-to-reach areas effectively. A high-quality LED flashlight with good brightness output is absolutely essential for illuminating dark cavities and undercarriage areas where rust commonly develops. The beam should be powerful enough to reveal surface irregularities and discolouration in shadowed spaces.

For physical testing of suspect areas, you'll need a chipping hammer or ball-peen hammer to probe questionable sections and test metal integrity. The sound and feel when tapping will immediately indicate whether the metal beneath is solid or compromised by corrosion.

A borescope or inspection camera represents professional-grade equipment that allows visual inspection inside enclosed frame sections through existing factory holes. This tool proves invaluable for examining the interior condition of chassis rails and detecting previous repairs, scale buildup, or structural damage that would otherwise remain completely hidden.

Additionally, keep a sharp knife or sturdy screwdriver readily available for carefully probing through rubber underseal or protective coatings to test the underlying metal condition. This technique allows you to verify metal integrity in areas where visual inspection alone proves insufficient.

Critical Inspection Zones: Where Hidden Rust Develops

Frame Rails and Chassis Components

Begin your systematic inspection by examining the main frame rails that run underneath the vehicle along each side. These structural components bear the vehicle's weight and represent critical safety elements. Focus particular attention on areas where frame sections join together, as these connection points often trap moisture and debris.

Pay special attention to the exhaust mounting areas and heat shields, as the thermal cycling from exhaust heat creates ideal conditions for accelerated corrosion. The constant heating and cooling process can cause protective coatings to crack and fail, allowing moisture penetration.

Enclosed Frame Cavities and Box Sections

Enclosed frame sections present the greatest challenge for rust detection because they trap road debris, moisture, and corrosive materials while remaining largely invisible during routine inspections. Even vehicles with perfect exterior appearance may harbour extensive internal corrosion within these enclosed areas.

Many manufacturers include small drainage holes in these sections, but inadequate drainage design often allows debris accumulation over time. Use your borescope to examine the interior condition through any accessible openings, looking for scale buildup, previous repair evidence, or structural deterioration.

Wheel Well Areas and Suspension Mounting Points

Wheel wells experience constant exposure to road spray, gravel impact, and trapped debris, making them particularly vulnerable to hidden rust development. Remove inner wheel arch liners where possible to inspect the metal surfaces beneath, as these plastic covers often conceal developing corrosion.

Suspension mounting points deserve careful attention because structural failure in these areas represents serious safety concerns. Look for rust development around shock absorber mounts, spring perches, and control arm attachment points.

Door Frames and Structural Seams

Inspect all door frame areas thoroughly, including the bottom edge of doors where drainage can become blocked. Water accumulation in door frames creates perfect conditions for rust development, particularly in the lower corners where debris settles.

Examine pinch weld seams around the entire vehicle perimeter, as these joining points between body panels frequently develop corrosion. The overlapping metal sections in these seams can trap moisture and accelerate rust formation.

Identifying Visual and Physical Rust Indicators

Surface Paint Defects and Bubbling

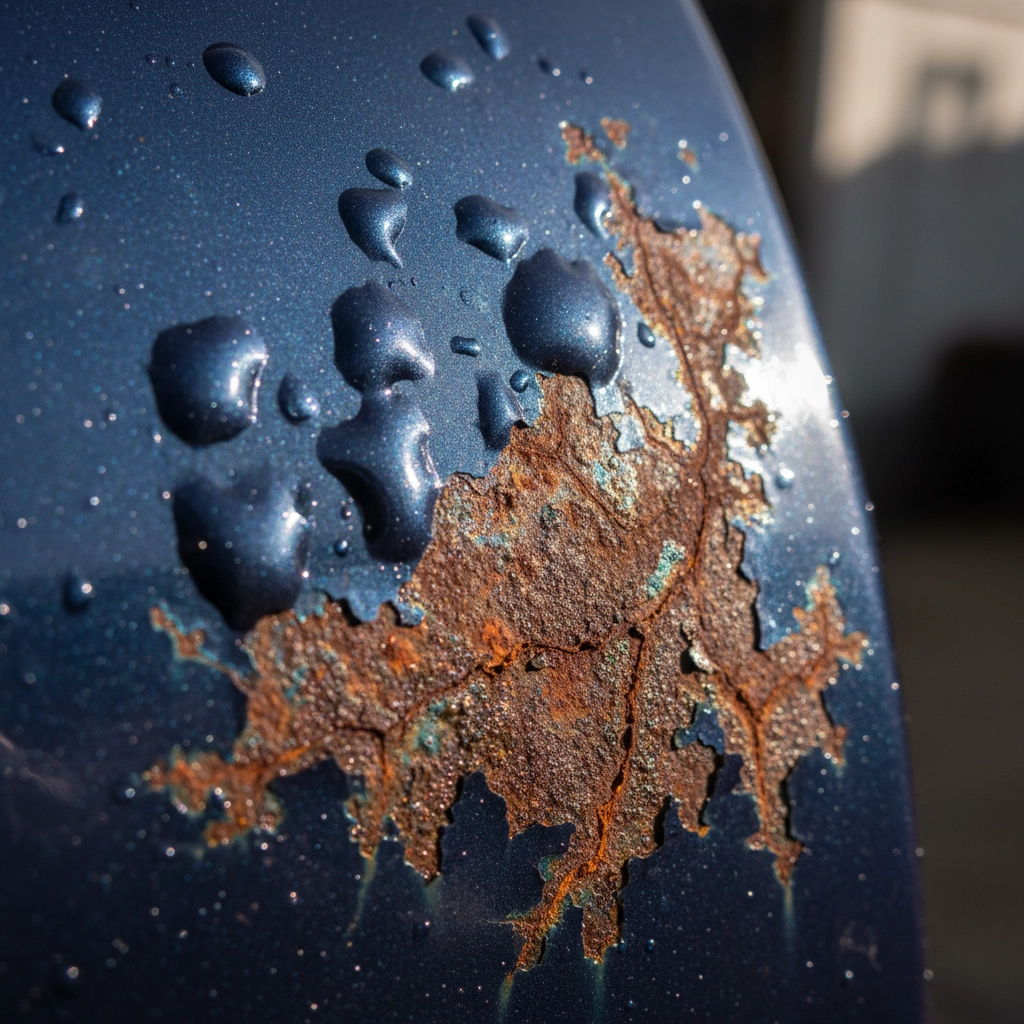

Paint bubbling or blistering represents one of the earliest visible indicators of underlying rust development. These raised areas in the paint surface indicate that corrosion has begun beneath the coating and is pushing upward as rust expands. Even small bubbles warrant immediate investigation, as they often indicate more extensive hidden damage.

Look for subtle colour variations or shadowing in painted surfaces, particularly around repair areas or high-stress zones. These visual cues may indicate previous rust treatment or ongoing corrosion beneath protective coatings.

Physical Testing Techniques

When probing suspect areas with your hammer or screwdriver, pay attention to both sound and resistance. Solid, healthy metal produces a clear ringing sound when tapped, while corroded areas create a dull thud or hollow sound. The physical resistance should feel firm and consistent – soft spots or areas that flex unusually indicate compromised metal integrity.

Press firmly on areas showing discolouration or paint defects to check for hollow sections or unusual flexibility. Healthy structural metal should feel solid and immovable under reasonable pressure.

Hidden Corrosion Behind Protective Elements

Carefully examine areas behind rubber seals, plastic trim pieces, and protective covers. These components often hide developing rust by creating moisture traps while concealing the corrosion from casual observation. Stone chip damage in wheel wells frequently develops into extensive hidden rust when protective underseal coating is compromised but debris accumulation masks the underlying problem.

Professional Inspection Services: When Expert Assessment Becomes Essential

While thorough owner inspection can identify many potential problems, professional assessment using hydraulic lifts and specialized equipment provides access to areas that remain impossible to examine properly from ground level. Professional rustproofing specialists possess the experience to identify subtle indicators that might escape notice during owner inspection.

When purchasing a used 4x4 or van, particularly vehicles with off-road exposure or commercial use history, professional pre-purchase inspection can reveal hidden structural issues before they become your responsibility. This investment in professional assessment often saves thousands in unexpected repair costs.

At Rustec, our comprehensive vehicle inspections include detailed photographic documentation of all findings, allowing you to understand exactly what areas require attention and prioritise any necessary remedial work before applying protective treatments.

Advanced Detection in High-Risk Vehicle Categories

Commercial Van Considerations

Commercial vehicles face accelerated corrosion due to higher mileage, frequent loading stress, and often inadequate maintenance schedules. Focus particular attention on rear door hinge areas, load floor mounting points, and side door tracks where repeated use creates wear points vulnerable to moisture penetration.

Examine cargo area tie-down points and floor-mounted equipment brackets, as these high-stress areas frequently develop fatigue cracks that allow corrosion to begin.

Off-Road Vehicle Specific Concerns

4x4 vehicles used for off-road activities face unique corrosion challenges from mud retention, stone damage, and water crossing exposure. Pay special attention to differential housings, transfer case areas, and underbody protection that may conceal damage from ground contact.

Rock sliders and underbody protection plates can trap debris and moisture against the vehicle structure, creating hidden corrosion environments. Remove these protective elements periodically for thorough inspection of the areas beneath.

Taking Action on Discovery Findings

Once you've identified areas of concern through systematic inspection, prompt action prevents minor issues from developing into major structural problems. Surface rust caught early responds well to treatment and protective coating application, while advanced structural corrosion may require professional repair before effective rust prevention measures can be applied.

Document your findings with photographs and measurements to track progression over time and establish baseline conditions for future reference. This documentation proves valuable for warranty claims, insurance purposes, and resale value preservation.

Professional Treatment Options

For vehicles showing early rust development or those requiring preventive protection, professional rustproofing services provide comprehensive cavity wax application, structural underseal treatment, and protective coating systems designed for long-term corrosion prevention.

Quality rustproofing treatments like our Life Long Dinitrol® system penetrate into existing corrosion, neutralise active rust, and provide ongoing protection against future moisture penetration. Our thorough preparation process includes complete undercarriage cleaning and detailed inspection to ensure all hidden problem areas receive appropriate treatment.

Maintaining Long-Term Structural Integrity

Regular inspection schedules become essential for maintaining awareness of developing corrosion issues before they compromise structural integrity or safety systems. Establish quarterly inspection routines focusing on the critical areas identified in this guide, with particular attention during spring months following winter road salt exposure.

Professional rustproofing treatment provides the foundation for long-term corrosion protection, but ongoing vigilance ensures early detection of any areas where protection may have been compromised through stone damage, wear, or aging.

Your 4x4 or van represents a significant investment in capability and utility. Protecting that investment through systematic rust detection and professional treatment ensures reliable service for years to come while maintaining optimal resale value and safety standards.

For comprehensive rust inspection and professional treatment services, contact Rustec to discuss your specific vehicle requirements and arrange a detailed assessment of your 4x4 or van's current condition.

Comments