How often should I reapply Lanoguard?

- Lloyd Saunders

- Dec 31, 2025

- 5 min read

Lanoguard has established itself as one of the UK's most trusted rust prevention solutions, offering effective protection against the harsh conditions that British vehicles face daily. However, many vehicle owners remain uncertain about the optimal reapplication schedule to maintain continuous protection. Understanding when and how often to reapply Lanoguard is crucial for maximising your investment and ensuring your vehicle remains rust-free throughout its lifetime.

The Standard Reapplication Schedule

Lanoguard should be reapplied at least once a year for standard vehicle applications. This annual schedule represents the minimum frequency required to maintain effective rust protection under typical UK driving conditions. The product has been specifically designed for yearly or seasonal applications, with each treatment providing up to 12 months of reliable protection.

However, the simple application process means there's considerable flexibility in your maintenance schedule. Many professional technicians recommend a bi-annual approach, applying Lanoguard in both autumn and spring. This enhanced schedule provides superior protection during the harshest months when road salt, moisture, and temperature fluctuations pose the greatest threat to your vehicle's undercarriage.

The autumn application prepares your vehicle for winter's aggressive conditions, while the spring reapplication addresses any degradation caused by months of salt exposure and provides fresh protection for the warmer months ahead.

Factors That Influence Reapplication Frequency

Environmental Exposure

UV exposure significantly affects Lanoguard's longevity. Areas of your vehicle exposed to direct sunlight will require more frequent attention than protected interior sections such as chassis rails and enclosed cavities. The outer surfaces of wheel arches, exposed suspension components, and any areas receiving direct solar radiation may need supplementary treatment between annual applications.

Driving Conditions

Your driving habits and environment directly impact how often you should reapply Lanoguard. Vehicles regularly driven on motorways experience greater salt spray exposure, while those frequently used off-road encounter mud, water, and debris that can accelerate product breakdown. Urban driving with frequent stop-start conditions and exposure to industrial pollutants may also necessitate more frequent reapplication.

Commercial vehicles and those used for towing heavy loads experience additional stress that can reduce protection intervals. Fleet managers operating vehicles in demanding conditions often implement quarterly inspection schedules to identify areas requiring early reapplication.

Seasonal Considerations

Winter conditions are particularly demanding on rust protection systems. Road salt, combined with temperature cycling between freezing and thaw conditions, creates an aggressive environment that challenges even the most robust treatments. Reapplying Lanoguard before winter begins is strongly advised, ideally in late autumn when temperatures remain suitable for proper curing.

Application-Specific Reapplication Guidelines

Standard Vehicle Protection

For cars, vans, and commercial vehicles used primarily on sealed roads, annual reapplication provides adequate protection. This schedule aligns with routine maintenance intervals and allows for coordination with MOT inspections or service schedules.

Motorcycle and Outdoor Equipment

Motorcycles require more frequent attention, with reapplication recommended every six months. The exposed nature of motorcycle components, combined with their vulnerability to weather conditions, necessitates this enhanced schedule. Lanoguard Moto spray specifically provides a minimum of six months protection, though quarterly applications are recommended for machines regularly used in challenging conditions.

Moto grease applications typically last around 12 months, making them suitable for less frequently used machines or those stored indoors during winter months.

4x4 and Off-Road Vehicles

Vehicles regularly used off-road face unique challenges that may require adjusted reapplication schedules. Mud, water crossings, and abrasive terrain can accelerate product wear, particularly on lower chassis areas and wheel arches. Consider six-monthly applications for heavily used off-road vehicles, with particular attention to areas receiving direct impact from debris and water.

Recognising When Reapplication Is Required

Visual Inspection Indicators

Regular inspection of treated areas helps identify when reapplication is necessary before protection fails completely. Look for areas where the Lanoguard film appears thin, cracked, or missing entirely. Exposed metal surfaces, particularly around bolt heads, welds, and high-stress areas, indicate immediate attention is required.

Seasonal Assessment Points

Conduct thorough inspections following winter conditions, checking for areas where salt exposure may have compromised protection. Spring inspections are particularly valuable, as they reveal any damage caused by winter conditions while allowing time for remedial treatment before the following season.

The Reapplication Process

Preparation Requirements

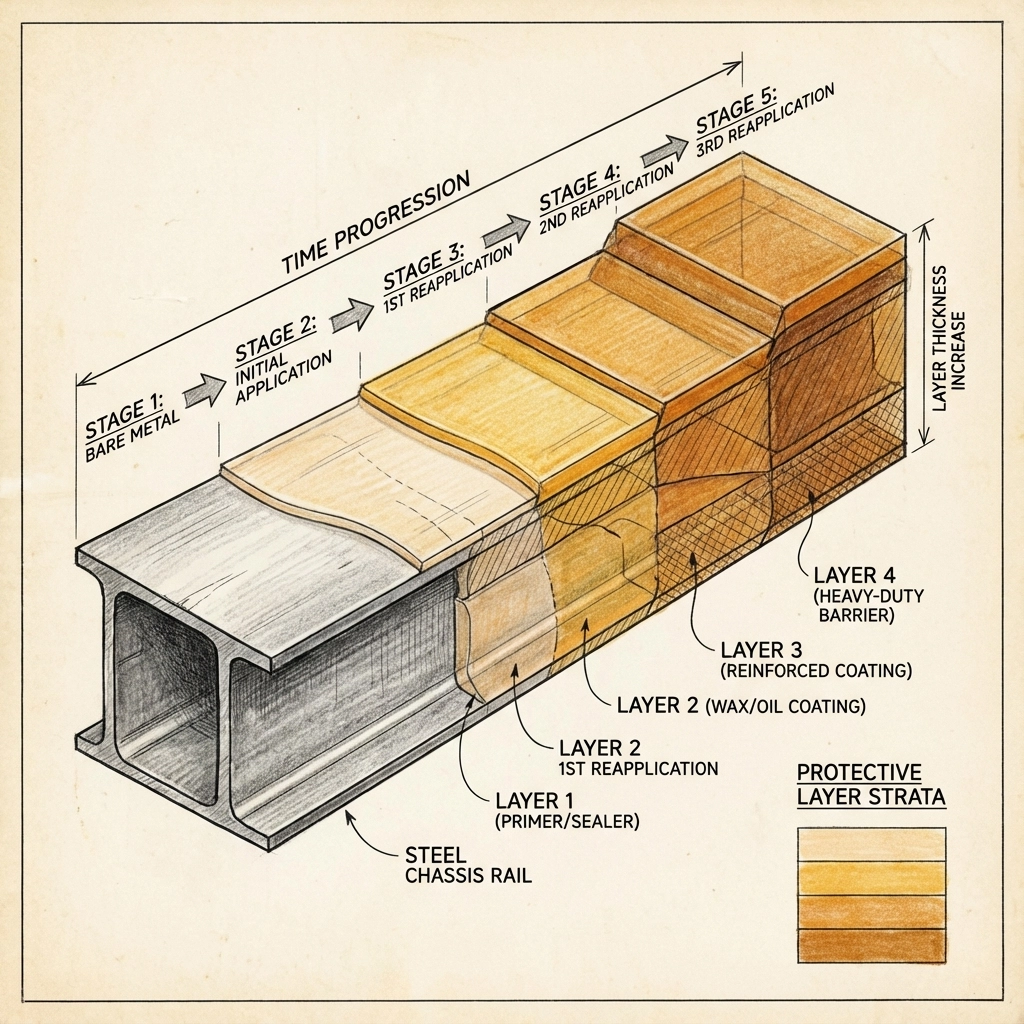

Top-up applications are significantly simpler than initial treatments. Begin with a thorough pressure wash of the undercarriage to remove accumulated dirt, salt, and debris. Unlike initial applications, you don't need to remove existing Lanoguard: new coats bond effectively with previous applications, building up protection layers over time.

Application Technique

Each reapplication adds to rather than replaces existing protection. Focus particularly on areas showing wear or exposure, while maintaining coverage across all previously treated surfaces. Pay special attention to drain holes, ensuring they remain clear while surrounding areas receive adequate protection.

The cumulative effect of multiple applications creates increasingly robust protection, with each layer contributing to overall system effectiveness.

Cost-Effectiveness of Regular Maintenance

Prevention vs. Repair

Regular reapplication is significantly more cost-effective than addressing rust damage after it occurs. The expense of annual or bi-annual Lanoguard treatment pales in comparison to structural repairs, panel replacement, or the impact on vehicle value caused by rust damage.

Long-Term Value Protection

Consistent rust protection directly contributes to vehicle resale value. Well-maintained vehicles with documented rust protection histories command premium prices in the used vehicle market, particularly for models known for rust susceptibility.

Professional vs. DIY Reapplication

DIY Considerations

Reapplication is well within the capabilities of most vehicle owners. The process requires basic equipment: pressure washer, suitable spray equipment, and safety gear. However, comprehensive coverage of complex areas such as chassis rails, suspension components, and door cavities requires careful attention and appropriate access equipment.

Professional Advantages

Professional reapplication ensures complete coverage and proper preparation. Experienced technicians possess the equipment and expertise to reach all vulnerable areas effectively, often identifying developing issues before they become serious problems.

Professional services typically include comprehensive inspection, documentation of treatment areas, and guidance on future maintenance schedules tailored to your specific vehicle and usage patterns.

Conclusion

Annual reapplication represents the minimum frequency for maintaining Lanoguard protection, with enhanced bi-annual schedules providing superior defence against UK conditions. Your specific requirements depend on vehicle type, usage patterns, and environmental exposure, with motorcycles and heavily used off-road vehicles requiring more frequent attention.

Regular maintenance is invariably more cost-effective than reactive repairs, protecting both your vehicle's structural integrity and financial value. Whether you choose DIY or professional application, consistency is key to long-term rust prevention success.

For comprehensive rust protection services and expert guidance on maintaining your vehicle's Lanoguard treatment, contact Rustec today. Our experienced technicians provide professional application services backed by our commitment to quality and long-term vehicle protection.

Comments