How fast does rust spread on a car?

- Lloyd Saunders

- Dec 19, 2025

- 5 min read

Car rust doesn't develop overnight, but under the right conditions, it can progress alarmingly quickly. With the combination of moisture, salt, and Britain's challenging climate, visible rust can appear on your vehicle in as little as one week following initial damage to protective coatings. Understanding the speed at which rust spreads is crucial for every car owner, as early intervention can save thousands in repair costs and preserve your vehicle's structural integrity.

The question of rust spreading speed isn't straightforward: it depends on numerous variables including steel quality, environmental exposure, and existing protective measures. What starts as a small paint chip can rapidly escalate into a significant structural concern if left untreated, particularly in the UK's moisture-rich environment.

The Science Behind Rust Development Speed

Rust formation is fundamentally an electrochemical process requiring three essential elements: iron, oxygen, and moisture. When these combine, iron oxide forms: the reddish-brown substance we recognise as rust. The speed of this process depends heavily on how readily these elements can interact.

Steel grade plays a pivotal role in determining rust spreading speed. High-grade steel used in premium vehicles offers superior resistance, with rust spreading significantly more slowly compared to lower-grade materials commonly found in budget vehicles. The molecular structure of higher-grade steel creates barriers that slow the oxidation process, buying vehicle owners valuable time for intervention.

Moisture availability acts as the primary accelerator. Even minimal exposure to water vapour can initiate the rusting process, but standing water or persistent dampness dramatically increases the reaction rate. Britain's maritime climate, with its near-constant humidity levels, creates ideal conditions for rapid rust development throughout much of the year.

Environmental Factors That Accelerate Rust Spreading

The UK's unique climate presents particular challenges for vehicle corrosion resistance. Road salt and de-icing chemicals used extensively during winter months don't just facilitate rust formation: they actively accelerate the spreading process. Salt acts as a catalyst, breaking down protective coatings and creating an electrolytic environment that can cause rust to appear within days of initial exposure.

Temperature fluctuations create additional stress on vehicle metalwork. The freeze-thaw cycles common in British winters cause water to expand by approximately 9% when frozen, forcing existing cracks wider and creating new pathways for moisture penetration. When temperatures rise, the accelerated chemical reactions drive rust formation at an increased rate.

Coastal environments present extreme challenges, with salt-laden air creating corrosive conditions even when vehicles aren't directly exposed to road salt. Vehicles regularly driven in coastal areas often show rust development significantly faster than those used inland, sometimes displaying visible corrosion within the first year of ownership.

Industrial pollutants, including sulphur dioxide and airborne contaminants, combine with atmospheric moisture to form acids that attack metal surfaces. Urban areas with heavy traffic or industrial activity can see accelerated rust formation, particularly on exposed undercarriage components.

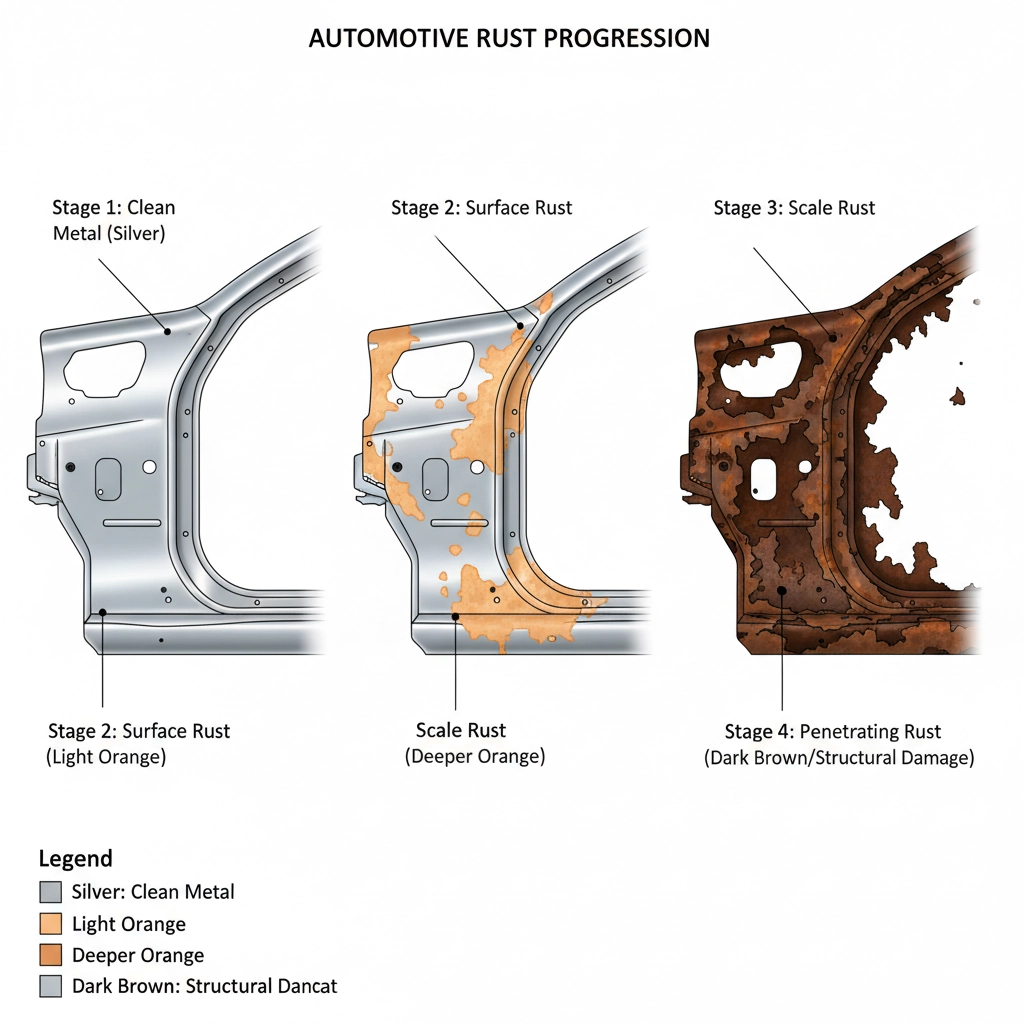

The Three Stages of Rust Progression

Understanding how rust progresses through distinct stages helps vehicle owners recognise the urgency of intervention at different points.

Stage One: Surface Rust typically appears first, affecting only the outermost layer of metal. At this stage, rust may appear as small spots or discoloration, often mistaken for dirt or staining. Surface rust can develop within 48 to 72 hours of protective coating damage under optimal conditions for corrosion. While concerning, surface rust remains relatively contained and responds well to professional treatment.

Stage Two: Scale Rust represents significant progression, with the oxidation process beginning to penetrate deeper into the metal structure. Characteristic flaking and scaling become visible, and the affected area begins expanding more rapidly. Without intervention, scale rust can develop from surface rust within 2-4 weeks under aggressive conditions.

Stage Three: Penetrating Rust marks the critical stage where structural integrity becomes compromised. At this point, rust has eaten through significant portions of the metal, creating holes and severely weakening the component. Penetrating rust can develop from scale rust within 2-6 months, depending on environmental exposure and the thickness of the original material.

Geographic Variations in Rust Development Speed

Northern England and Scotland experience particularly aggressive rust development due to extended winter periods, frequent freeze-thaw cycles, and heavy road salt usage. Vehicles in these regions often require more frequent protective treatment applications and show visible rust development up to 30% faster than southern counterparts.

Coastal regions across the UK present unique challenges, with salt air creating year-round corrosive conditions. Vehicles regularly exposed to coastal environments may develop rust 2-3 times faster than those used exclusively inland, even without direct salt exposure.

Urban areas with heavy traffic and industrial activity often see accelerated rust development due to increased pollutant exposure and frequent stop-start driving conditions that trap moisture and contaminants in hard-to-reach areas.

Vehicle-Specific Rust Development Patterns

Commercial vehicles and vans often experience faster rust development due to heavier loading, more frequent exposure to harsh conditions, and longer intervals between detailed cleaning. The additional weight stress can accelerate the breakdown of protective coatings, allowing rust to establish more quickly.

4x4 vehicles and off-road enthusiasts' cars face unique challenges from mud, water, and debris that can compromise protective treatments. Off-road driving exposes vehicles to conditions that can initiate rust formation within hours of protective coating damage.

Electric vehicles present interesting considerations, as their typically newer construction incorporates modern rust-resistant materials, but their increased weight and different usage patterns may affect long-term corrosion resistance.

Critical Time Windows for Intervention

The first 24-48 hours following paint or protective coating damage represent the optimal intervention window. Immediate cleaning and temporary protection can prevent rust initiation entirely, saving significant costs and complications.

Week one to month one represents the crucial period for professional assessment and treatment. Surface rust developing during this timeframe responds excellently to professional rustproofing treatments, with proper application capable of halting progression entirely.

Month one to six marks the transition period where rust may progress from surface to scale rust. Professional intervention remains highly effective, though more extensive preparation may be required before protective treatment application.

Beyond six months, rust typically requires removal and repair before protective treatment application, significantly increasing costs and complexity.

Professional Prevention Strategies

Comprehensive rustproofing applied preventively offers the most effective protection against rapid rust development. Professional-grade treatments like Dinitrol create long-lasting barriers that significantly slow the oxidation process, even under aggressive conditions.

Regular maintenance schedules including thorough undercarriage cleaning, drain hole clearing, and protective coating inspection help identify potential issues before rust establishes. Professional services can detect early-stage rust development that vehicle owners might miss during routine inspections.

Seasonal preparation becomes particularly important given Britain's challenging climate. Pre-winter protective treatment application and post-winter assessment help maintain optimal protection during the most aggressive corrosion periods.

The Economics of Early Intervention

The financial implications of rust development speed cannot be overstated. Early intervention through professional rustproofing typically costs hundreds of pounds, while structural rust repair can easily reach thousands. Vehicle depreciation accelerates significantly once visible rust develops, often exceeding the cost of preventive treatment within the first year.

Warranty considerations also factor into timing decisions. Many vehicle warranties exclude corrosion damage that results from inadequate maintenance, making preventive rustproofing not just economically sensible but potentially essential for warranty protection.

Understanding rust development speed empowers vehicle owners to make informed decisions about protection timing. With rust capable of appearing within days and progressing to structural damage within months, proactive professional rustproofing represents both financial wisdom and responsible vehicle stewardship. For comprehensive rust prevention solutions tailored to your vehicle and usage patterns, professional assessment ensures optimal protection against Britain's challenging corrosive environment.