How do I stop my Hilux from rusting?

- Lloyd Saunders

- 6 days ago

- 6 min read

The Toyota Hilux has earned its reputation as one of the world's most dependable pickup trucks, but even this legendary vehicle isn't immune to the persistent threat of rust. If you own a Hilux, you've likely invested in it for its durability and reliability, which makes protecting it from corrosion absolutely essential for maintaining its value and performance over the long term.

Rust prevention on your Hilux requires a comprehensive approach that combines premium protective coatings, regular maintenance, and targeted protection of vulnerable areas. The key is implementing a proactive strategy before rust has a chance to establish itself, as prevention is always more effective and cost-efficient than attempting repairs after corrosion has taken hold.

Why Hilux Vehicles Are Particularly Susceptible to Rust

The Toyota Hilux's robust construction and frequent use in demanding conditions make it especially vulnerable to rust formation. These vehicles are often used for commercial purposes, off-road adventures, and heavy-duty applications that expose the chassis and underbody to harsh environmental conditions.

UK road conditions present unique challenges for Hilux owners. The combination of road salt during winter months, persistent moisture from frequent rainfall, and debris from construction sites or agricultural environments creates an ideal environment for corrosion to develop. The Hilux's design, while engineered for strength, includes numerous areas where moisture, salt, and contaminants can accumulate and remain in contact with metal surfaces.

Factory protection on modern Hilux vehicles, while improved compared to older models, still falls short of providing comprehensive long-term protection against the aggressive corrosive conditions commonly encountered in UK environments. This is particularly true for vehicles used in coastal areas, where salt air accelerates the corrosion process, or those regularly exposed to agricultural chemicals and road salt.

The Science Behind Effective Rust Prevention

Successful rust prevention relies on creating an impermeable barrier between metal surfaces and the environmental factors that cause corrosion. This barrier must be durable enough to withstand abrasion from road debris, flexible enough to accommodate the vehicle's movement, and chemically resistant to road salt and other corrosive substances.

Professional-grade protective coatings like Dinitrol and Lanoguard work by forming a continuous film over metal surfaces that prevents moisture and oxygen from reaching the steel. These products penetrate into seams, joints, and crevices where corrosion typically initiates, providing comprehensive protection that extends far beyond what surface treatments can achieve.

The most effective approach combines cavity wax treatments for internal structural members with comprehensive underbody protection for exposed chassis components. This dual approach ensures that both visible and hidden areas receive appropriate protection tailored to their specific exposure conditions and accessibility for future maintenance.

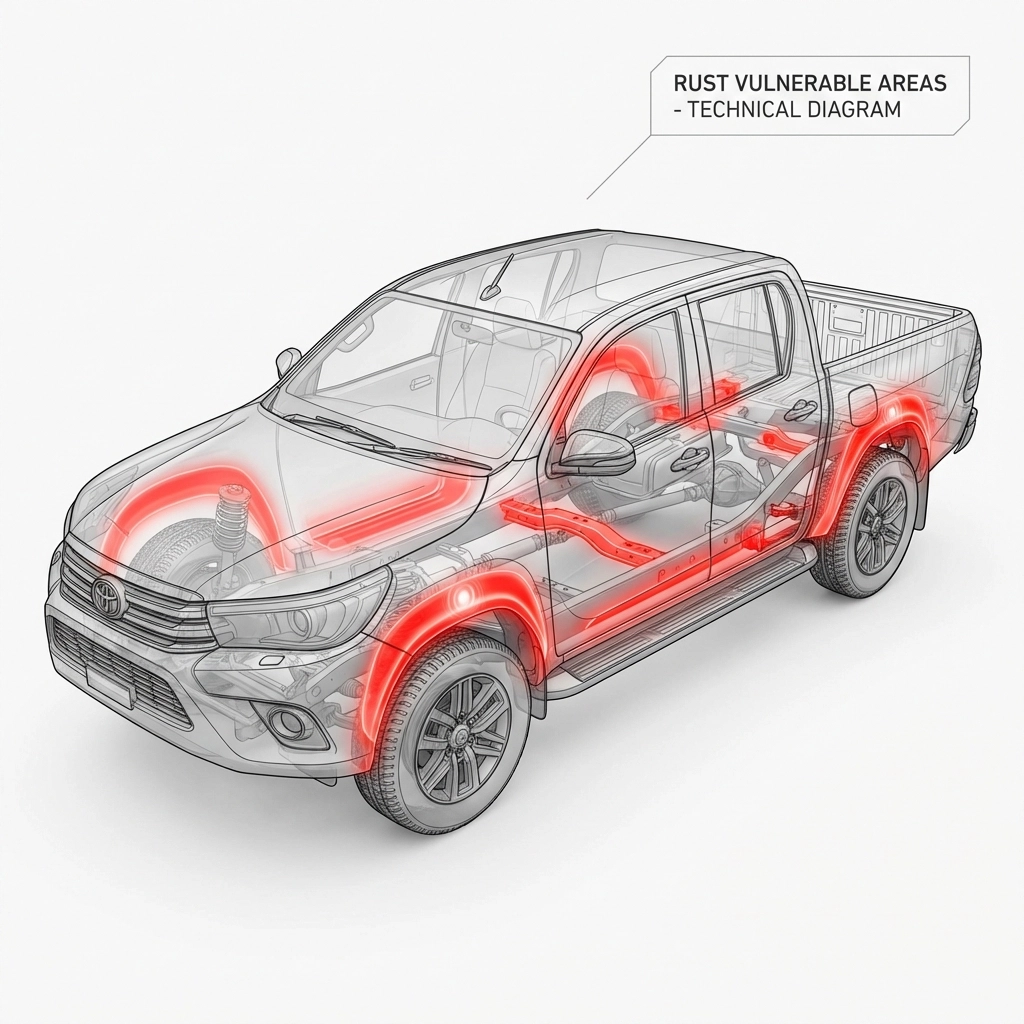

Critical Vulnerable Areas on Your Hilux

Understanding where rust typically begins on Hilux vehicles allows you to focus protective efforts where they'll have the greatest impact. The rear chassis section is particularly susceptible, especially around the rear leaf spring mounting points and the area behind the rear wheels where road spray concentrates.

The chassis rails running along the vehicle's length require special attention, particularly at mounting points for suspension components, towbars, and other accessories. These areas experience stress concentrations that can compromise protective coatings, creating entry points for moisture and contaminants.

Wheel arches on the Hilux accumulate significant amounts of road debris and moisture, making them prime locations for rust initiation. The design of these areas often includes seams and joints that are difficult to clean thoroughly, allowing contaminants to remain in contact with metal surfaces for extended periods.

Door sills and lower body panels, while not structural components, significantly impact the vehicle's appearance and can affect resale value when rust becomes visible. These areas are constantly exposed to road spray and benefit from both protective coatings and regular cleaning attention.

Professional Protective Coating Solutions

Premium protective coatings represent the most effective long-term solution for preventing rust on your Hilux. Dinitrol products, recognised as the industry standard for professional rust prevention, offer superior adhesion and durability compared to consumer-grade alternatives. The Dinitrol system includes specific products designed for different applications, from penetrating cavity waxes to tough underbody coatings.

Lanoguard provides an alternative approach using lanolin-based formulations that offer excellent penetration properties and environmental friendliness. This product is particularly effective at displacing moisture from metal surfaces and provides long-lasting protection even in challenging conditions.

The application process for professional coatings requires meticulous preparation to ensure optimal results. The underbody must be thoroughly cleaned using high-pressure washing and steam cleaning to remove all contaminants, loose rust, and existing protective materials that might prevent proper adhesion of new coatings.

Following preparation, protective coatings are applied using professional spray equipment that ensures even coverage and proper penetration into all areas. The vehicle requires adequate curing time before returning to service, typically 24 hours under controlled conditions.

Comprehensive Application Process

Effective rustproofing begins with a thorough inspection to identify existing rust, damage to current protection, and areas requiring special attention. This assessment determines the scope of preparation work needed and allows for proper material planning.

The cleaning phase involves removing accumulated dirt, oil, and road salt using high-pressure washing and steam cleaning equipment. Any loose rust must be removed using appropriate mechanical methods, and the surface must be completely dry before coating application begins.

Professional application requires systematic coverage of all accessible surfaces, with particular attention paid to areas identified as vulnerable during the inspection phase. Cavity wax is injected into structural members through existing drain holes or specially drilled access points, ensuring internal protection of box sections and other enclosed areas.

Quality control during application involves documenting coverage areas and film thickness to ensure consistency throughout the vehicle. Professional installations include photographic documentation showing before and after conditions, providing valuable reference material for future maintenance planning.

Ongoing Maintenance Requirements

Even the highest quality protective coatings require ongoing maintenance to ensure continued effectiveness. Regular washing is essential, particularly focusing on the underbody and wheel wells where contaminants accumulate. High-pressure washing helps remove road salt and debris before they can compromise protective coatings.

Annual inspection of protected areas allows for early identification of coating damage or wear. Areas showing signs of wear should receive touch-up applications promptly to prevent moisture penetration and rust initiation. This proactive approach maintains protection integrity and extends the service life of the original treatment.

Reapplication schedules depend on operating conditions and the specific products used. Vehicles operating in harsh conditions or covering high annual mileages may require more frequent attention, while those used primarily for light duty applications may achieve longer service intervals.

Professional maintenance programmes offer the advantage of expert inspection and precise application of touch-up materials. These services ensure that protection remains effective throughout the vehicle's service life and can provide documentation supporting warranty claims or resale value assertions.

Professional Installation Versus DIY Approaches

While DIY rustproofing products are available, professional installation offers significant advantages in terms of coverage quality, product selection, and long-term effectiveness. Professional installers have access to commercial-grade products not available to consumers and possess the equipment necessary for proper surface preparation and application.

The complexity of modern vehicle construction, with its numerous electrical components, sensors, and emissions control systems, requires careful masking and application techniques to avoid damage or interference. Professional installers understand these requirements and have the experience necessary to achieve comprehensive protection without compromising vehicle systems.

Warranty coverage is another important consideration when comparing professional and DIY approaches. Professional installations typically include comprehensive warranties covering both materials and workmanship, providing peace of mind and protection against defective application or premature coating failure.

Investment Protection and Long-term Benefits

Quality rustproofing represents a sound investment in your Hilux's long-term value and reliability. The cost of comprehensive protection is typically recovered through enhanced resale value, reduced maintenance requirements, and extended vehicle service life.

Professional rustproofing can significantly impact insurance considerations, particularly for commercial vehicles where corrosion-related repairs can result in extended downtime and increased operating costs. Many commercial operators find that proactive rust prevention reduces total cost of ownership and improves fleet reliability.

The documentation provided with professional rustproofing services supports warranty claims and demonstrates proactive maintenance to potential buyers, enhancing resale value and marketability. This documentation becomes particularly valuable for commercial vehicles where maintenance records directly impact residual values.

Protecting your Hilux from rust requires a comprehensive approach combining premium protective coatings, regular maintenance, and professional expertise. The investment in quality rust prevention pays dividends through enhanced longevity, maintained appearance, and preserved value throughout your vehicle's service life.

Comments