Do modern cars rust?

- Lloyd Saunders

- Dec 31, 2025

- 5 min read

Yes, modern cars absolutely rust, despite significant advances in manufacturing technology and factory-applied protective coatings. While automotive manufacturers have made considerable improvements in corrosion resistance over the past decades, no vehicle is completely immune to rust formation. Understanding why modern cars still succumb to corrosion: and what you can do about it: is essential for maintaining your vehicle's structural integrity and long-term value.

Why Modern Cars Still Rust Despite Manufacturing Advances

The automotive industry has invested heavily in rust prevention technologies. Modern vehicles benefit from galvanised steel components, advanced paint systems, and sophisticated protective coatings applied during manufacturing. However, these defenses are not foolproof against the persistent threat of corrosion.

Lighter metal alloys used in contemporary vehicle construction present new challenges. Manufacturers have increasingly adopted these materials to improve fuel efficiency and reduce overall vehicle weight. While these alloys offer performance benefits, they often lack the inherent corrosion resistance of traditional steel components, making them more susceptible to rust under specific environmental conditions.

The protective coatings and paint layers integrated by manufacturers provide an initial barrier against moisture and corrosive elements. However, these treatments gradually deteriorate through normal wear, exposure to UV radiation, and mechanical damage from road debris. Even microscopic scratches or chips can compromise the protective barrier, creating entry points for moisture and accelerating rust formation.

Environmental Factors That Accelerate Rust in Modern Vehicles

Road salt remains the primary accelerant of automotive corrosion in the UK. Local authorities apply thousands of tonnes of salt to British roads during winter months to improve driving safety. This salt creates an aggressive corrosive environment that attacks metal components, particularly in hidden areas where salt accumulates and moisture persists.

Coastal environments present additional challenges for vehicle owners. Salt-laden air increases humidity levels and introduces corrosive particles that settle on vehicle surfaces. Vehicles parked near the coast experience accelerated corrosion rates, even when not directly exposed to sea spray.

Industrial pollutants contribute significantly to rust formation. Airborne contaminants from manufacturing facilities, power stations, and urban environments create acidic conditions that attack protective coatings and underlying metal surfaces. Vehicles operating in industrial zones or heavily trafficked urban areas face heightened corrosion risks.

Humidity levels play a crucial role in rust development. The UK's naturally high humidity creates ideal conditions for oxidation, particularly when combined with temperature fluctuations that cause condensation to form in vehicle cavities and hidden spaces.

Hidden Vulnerabilities in Modern Car Design

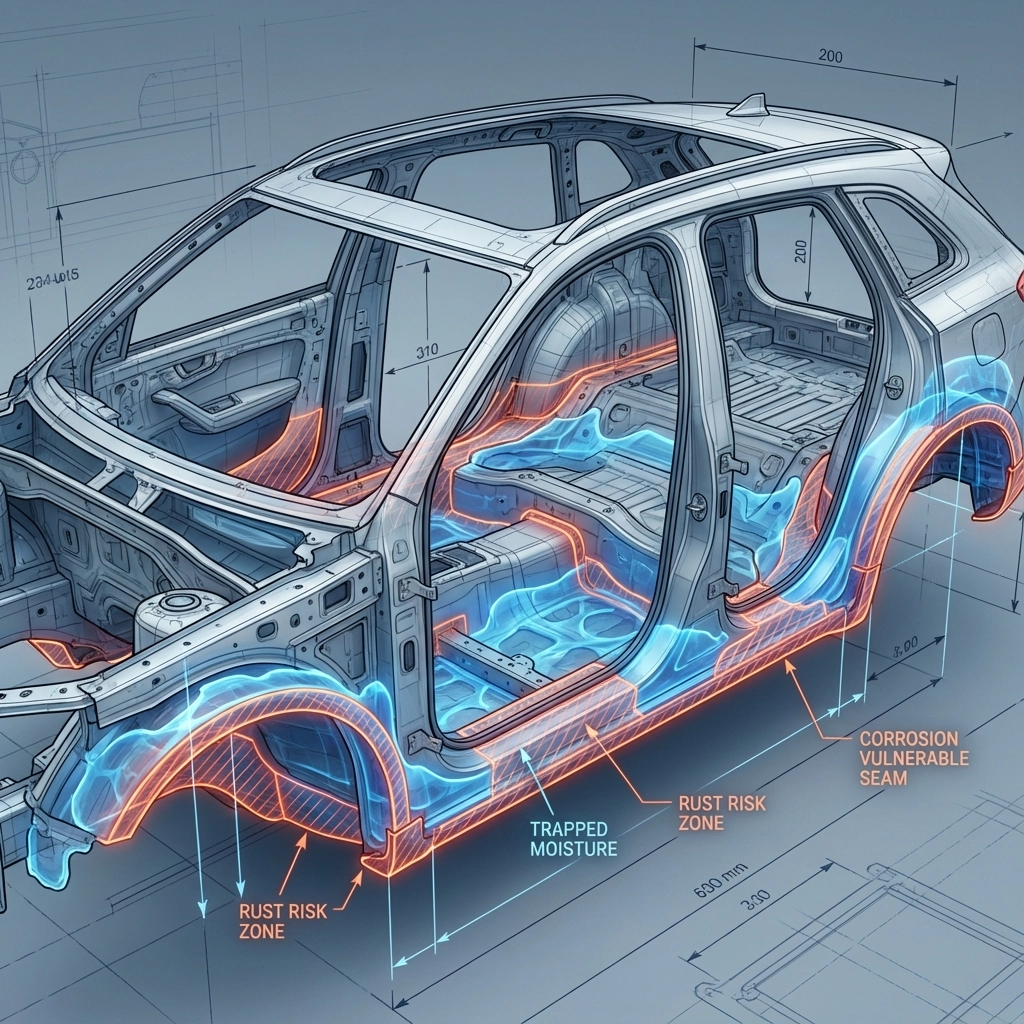

Contemporary vehicle design often prioritises aerodynamics, fuel efficiency, and interior space over traditional rust prevention considerations. This has created new vulnerability areas that require particular attention.

Complex body structures with multiple joints, seams, and hidden cavities provide ideal environments for moisture accumulation. Modern cars feature sophisticated crumple zones, sound deadening materials, and aerodynamic elements that can trap water and accelerate corrosion in areas difficult to inspect or treat.

Electronic integration throughout modern vehicles creates additional challenges. Protective treatments must be carefully selected to avoid interference with sensitive electronic components, sensors, and wiring systems. This constraint can limit the thoroughness of traditional rust prevention applications.

The Reality of Factory Rust Protection

Manufacturer warranties typically cover structural corrosion for extended periods, often 10-12 years. However, these warranties usually apply only to perforation corrosion: rust that completely penetrates the metal: rather than surface rust or cosmetic corrosion that can significantly impact vehicle appearance and value.

Factory-applied treatments vary considerably between manufacturers and model ranges. Economy vehicles often receive minimal corrosion protection compared to premium models, leaving owners of standard vehicles particularly vulnerable to rust development.

The warranty fine print often excludes damage caused by stone chips, accidents, or inadequate maintenance. This means that even minor paint damage can void corrosion protection, leaving vehicle owners responsible for rust treatment and repair costs.

Why Professional Rust Prevention Remains Essential

Given the limitations of factory protection and the harsh UK environment, professional rust prevention treatments provide comprehensive protection that factory coatings cannot match. Advanced products like Dinitrol offer superior penetration and longevity compared to standard manufacturing treatments.

Cavity wax injection reaches areas that factory treatments often miss. Professional technicians use specialised equipment to access door frames, sills, and chassis cavities where moisture accumulates and rust typically begins. This thorough approach provides protection in critical areas that determine structural integrity.

Regular reapplication maintains protective barriers as they naturally deteriorate. Professional treatments are designed for periodic renewal, ensuring continuous protection throughout the vehicle's operational life rather than relying on diminishing factory coatings.

Specific Rust Risks for Different Vehicle Types

Commercial vehicles face particularly aggressive corrosion conditions due to heavy loading, frequent use, and extended exposure to harsh environments. Vans, pickup trucks, and commercial fleet vehicles require robust protection strategies that account for their demanding operational requirements.

4x4 and off-road vehicles encounter unique challenges including mud retention, water crossings, and stone chip damage from rough terrain. These vehicles benefit from comprehensive undercarriage protection that withstands mechanical damage while providing long-term corrosion resistance.

Classic and specialist vehicles often feature older metallurgy and limited factory protection. These vehicles require tailored rust prevention approaches that respect original specifications while providing modern protection standards.

The Economics of Rust Prevention

Preventive treatment costs represent a fraction of potential repair expenses. Professional rustproofing typically costs several hundred pounds, while structural rust repairs can reach thousands of pounds depending on the extent of damage and vehicle type.

Resale value protection provides additional economic benefits. Vehicles with comprehensive rust prevention maintain higher market values and attract quality-conscious buyers. Independent valuations consistently show premium pricing for well-maintained, rust-free vehicles compared to those showing corrosion damage.

Insurance considerations may also favour proactive rust prevention. Some insurers recognise professional treatments as risk reduction measures, potentially influencing premium calculations and claim assessments.

Recommended Protection Strategy

Immediate treatment for new vehicles provides optimal results. Professional rust prevention applied within the first year of ownership ensures comprehensive protection before any corrosion begins. This proactive approach maximises treatment effectiveness and long-term value.

Annual inspections help identify potential issues before they develop into serious problems. Professional technicians can spot early signs of coating deterioration, mechanical damage, or emerging rust spots that require attention.

Comprehensive cavity treatment using premium products like Dinitrol provides the thorough protection modern vehicles require. This approach addresses the specific vulnerabilities of contemporary vehicle design while providing long-term corrosion resistance.

Conclusion

Modern cars definitely rust, despite impressive advances in manufacturing technology and factory-applied protective treatments. The combination of lightweight materials, complex designs, and aggressive UK environmental conditions ensures that professional rust prevention remains essential for maintaining vehicle integrity and value.

Rather than relying solely on factory protection, discerning vehicle owners invest in comprehensive professional treatments that provide superior coverage and longevity. This proactive approach ensures their vehicles remain structurally sound and retain maximum value throughout their operational life.

For vehicle owners seeking premium rust prevention solutions, professional Dinitrol treatments offer the comprehensive protection that modern cars require to withstand UK conditions. Contact our technical specialists to discuss the optimal protection strategy for your specific vehicle and requirements.

Comments