Do electric vehicles need rustproofing?

- Lloyd Saunders

- 5 days ago

- 4 min read

The electric vehicle revolution has transformed how we think about automotive maintenance, with many EV owners believing their vehicles are immune to traditional concerns like rust and corrosion. However, this assumption proves both costly and dangerous. Electric vehicles absolutely need rustproofing, just as much as conventional petrol and diesel vehicles.

While advanced battery technology and sophisticated engineering define modern electric vehicles, the fundamental reality remains unchanged: EVs are constructed from steel, aluminium, and other metals that remain vulnerable to corrosion when exposed to moisture, road salt, and environmental contaminants.

The Electric Vehicle Rust Misconception

Many EV owners mistakenly believe their vehicles possess inherent rust immunity due to their advanced technology and often premium positioning in the market. This dangerous misconception stems from the assumption that electric powertrains somehow protect the vehicle's structural components from environmental damage.

The truth proves far different. Electric vehicles face identical environmental challenges to conventional vehicles. UK roads, particularly during winter months when local authorities apply substantial quantities of road salt, create aggressive corrosive conditions that affect all vehicles regardless of their powertrain technology.

Why Electric Vehicles Face Greater Rust Risks

The electrical nature of EVs introduces additional rust-related risks that conventional vehicle owners rarely encounter. When corrosion affects electrical components, battery connections, or high-voltage wiring systems, the consequences prove far more severe and expensive than traditional mechanical failures.

Rust formation around electrical systems can compromise conductivity, leading to:

System malfunctions affecting vehicle performance and safety

Reduced battery performance and shortened lifespan

Expensive component replacement costs exceeding conventional repair expenses

Safety hazards from compromised high-voltage systems

Electric vehicles also typically weigh significantly more than comparable conventional vehicles due to their battery packs. This additional weight places greater stress on suspension components, chassis mounting points, and structural elements, potentially accelerating rust formation under pressure and moisture exposure.

Critical Rust-Prone Areas in Electric Vehicles

Electric vehicle design creates specific vulnerability points that require targeted protection:

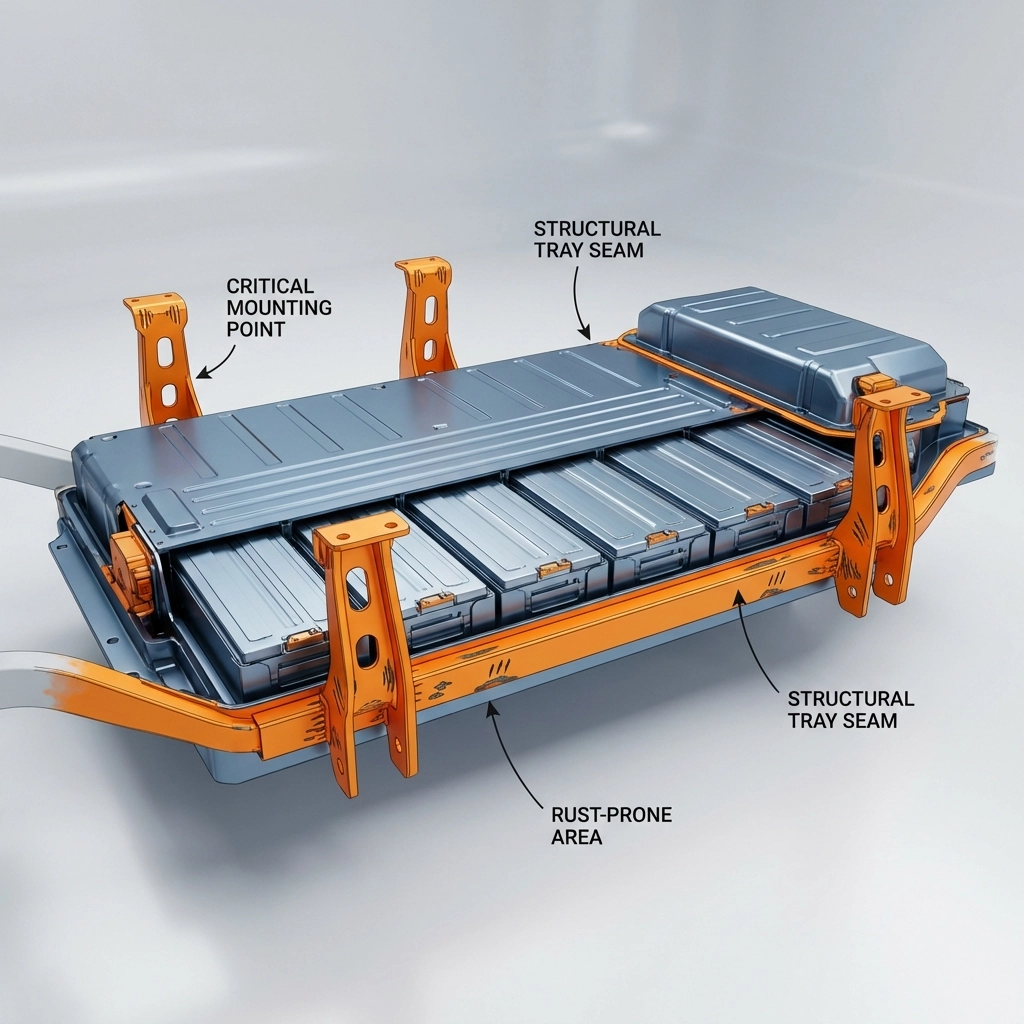

Battery Tray and Mounting Systems

The battery tray represents the most critical area requiring protection in any electric vehicle. Corrosion around battery tray seams proves extremely costly to repair and requires early preventative protection. The substantial weight of EV battery packs creates stress concentrations at mounting points, making these areas particularly susceptible to corrosion-induced failure.

Rocker Panels and Wiring Harnesses

EV rocker panels often house essential wiring harnesses and electrical components. Corrosion in these areas can expose critical cables and affect sensors, door mechanisms, and charging systems. The complex electrical architecture of modern EVs means that seemingly minor corrosion issues can cascade into major system failures.

Suspension and Brake Components

The increased weight of electric vehicles places additional stress on steel control arms, subframe joints, and mounting brackets. This elevated loading causes rust to spread faster under combined pressure and moisture exposure. Brake components face particular challenges, as many EVs utilise regenerative braking systems that can allow conventional brake components to deteriorate from reduced use.

Underbody and Wheel Well Areas

These areas face constant exposure to salt, moisture, and road debris. Electric vehicles often feature additional underbody panelling to protect battery systems and improve aerodynamics, creating potential moisture traps if not properly protected.

Factory Protection Limitations

New electric vehicles typically receive factory-applied corrosion protection during manufacturing. However, this protection provides adequate coverage for approximately three years before deteriorating significantly. Once factory protection fails, rust formation accelerates rapidly, particularly in concealed areas where moisture naturally accumulates.

Professional rustproofing should be applied as early as possible to maintain clean metal surfaces and prevent future corrosion. Early application proves far more effective and economical than attempting to treat established rust formation.

Selecting Appropriate Rustproofing Products for EVs

When selecting rustproofing products for electric vehicles, traditional approaches require modification to accommodate electrical systems safely.

Avoid Oil-Based Products

Traditional oil-based rustproofing sprays pose significant risks to electric vehicles. These products can drip onto electrical components, potentially causing short circuits, insulation breakdown, or component damage. The complex electrical architecture of EVs makes even minor contamination potentially catastrophic.

Choose EV-Safe Products

Instead, select drip-free, solvent-free products specifically designed for electrical systems. These products should possess:

High dielectric strength to prevent electrical interference

Non-conductive formulation to protect sensitive electronics

Long-lasting protection without requiring frequent reapplication

Compatibility with modern materials including plastics and rubber components

Products specifically labelled as EV-safe provide the optimal balance of corrosion protection and electrical system compatibility.

Professional Application Benefits

Professional rustproofing services offer significant advantages for electric vehicle owners:

Expertise and Equipment

Professional technicians possess the knowledge and specialised equipment necessary to safely protect electric vehicles without compromising electrical systems. They understand the specific requirements of different EV models and can tailor protection strategies accordingly.

Comprehensive Coverage

Professional application ensures complete protection of all vulnerable areas, including difficult-to-access locations that DIY attempts often miss. This comprehensive coverage proves essential for long-term protection effectiveness.

Warranty Protection

Professional rustproofing does not void manufacturer warranties, provided the work is completed by qualified technicians using appropriate products and methods. This protection ensures that your investment remains secure while extending your vehicle's operational lifespan.

Long-Term Value Protection

Rustproofing represents a crucial investment in your electric vehicle's long-term value and performance. The sophisticated electrical systems and expensive battery components in EVs make corrosion protection particularly valuable:

Extended component lifespan reduces replacement costs

Maintained resale value through superior condition preservation

Enhanced safety through reliable electrical system performance

Reduced maintenance costs over the vehicle's operational life

The Rustec Advantage for Electric Vehicles

At Rustec, we understand the unique requirements of electric vehicle protection. Our comprehensive rustproofing services utilise premium, EV-compatible products applied by experienced technicians who understand the intricacies of modern electric vehicles.

Our meticulous application process ensures complete protection without compromising your vehicle's sophisticated electrical systems. We provide detailed documentation of our work and stand behind our service with robust warranties that complement rather than conflict with your manufacturer's coverage.

Conclusion

Electric vehicles require the same level of rust protection as conventional vehicles, with additional considerations for their complex electrical systems. The misconception that EVs possess inherent rust immunity has cost many owners thousands of pounds in avoidable repairs.

Early professional rustproofing represents the most effective strategy for protecting your electric vehicle investment. By choosing appropriate products and professional application, you ensure that your EV remains rust-free throughout its operational life while maintaining optimal performance and value.

Don't let misconceptions about electric vehicle technology expose your investment to preventable corrosion damage. Contact Rustec today to discuss comprehensive rust protection solutions specifically designed for your electric vehicle's unique requirements.

Comments