Do electric vehicles need rustproofing?

- Lloyd Saunders

- Nov 15, 2025

- 5 min read

The short answer is yes – electric vehicles absolutely need rustproofing, despite common misconceptions suggesting otherwise. While EV technology has revolutionised automotive powertrains, the fundamental challenge of corrosion protection remains unchanged for the majority of vehicle components.

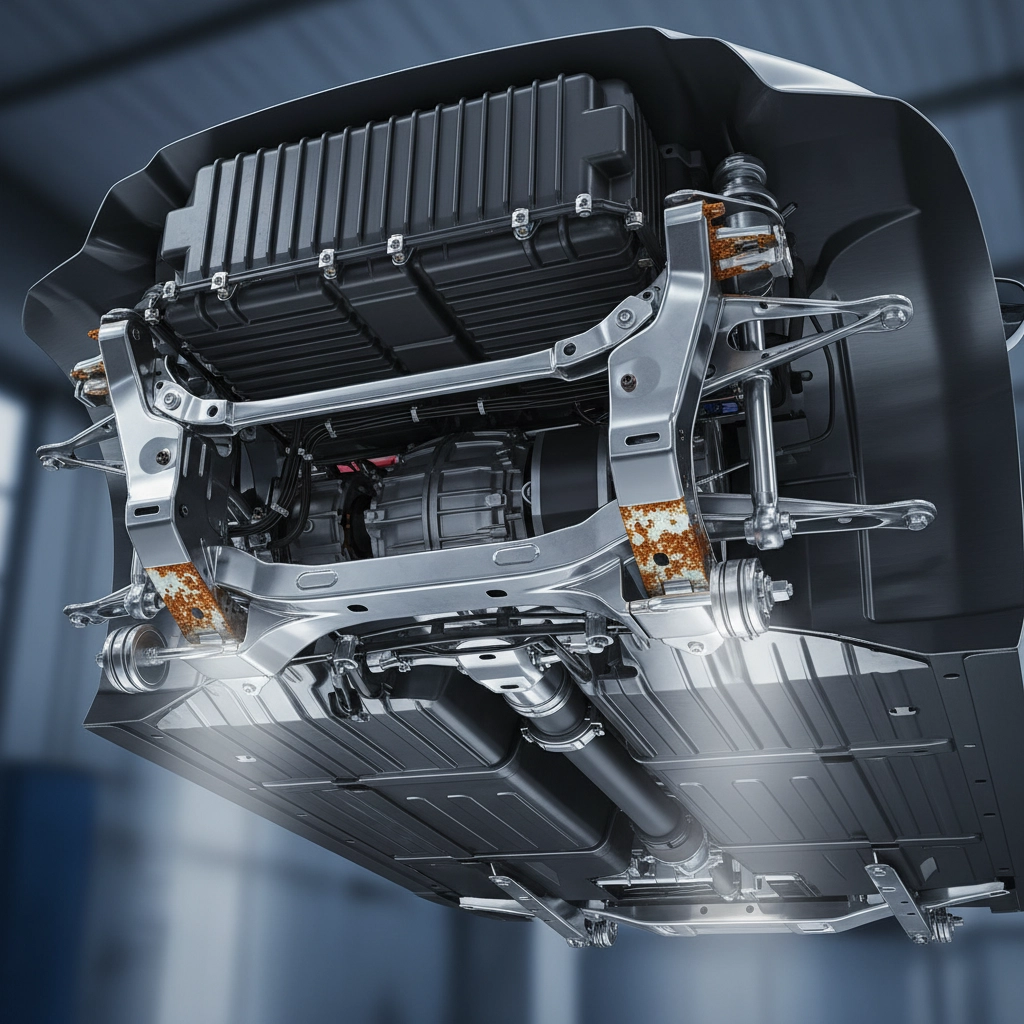

Many EV owners assume their vehicles are somehow immune to rust due to advanced battery technology or lightweight construction. This assumption proves costly when rust begins forming on critical chassis components, suspension systems, and structural elements that remain as vulnerable as those found in traditional combustion engine vehicles.

Why Electric Vehicles Are Still Vulnerable to Rust

Electric vehicles utilise many of the same steel-based structural components as conventional cars. The chassis, suspension arms, brackets, fasteners, and subframes are typically manufactured from steel alloys that require comprehensive corrosion protection. While manufacturers often incorporate lightweight aluminium body panels to improve range and efficiency, the underlying structural framework remains predominantly steel-based.

The electrical nature of EVs actually introduces additional rust-related risks. When corrosion affects electrical components, battery connections, or high-voltage wiring systems, the consequences prove far more severe and expensive than traditional mechanical failures. Rust can compromise electrical conductivity, leading to system malfunctions, reduced battery performance, or complete electrical failures requiring extensive repairs.

Road salt, moisture, and environmental contaminants affect EV components identically to conventional vehicles. The undercarriage faces constant exposure to corrosive elements, particularly during winter months when road salt application intensifies. These conditions create ideal environments for rust formation, regardless of the vehicle's propulsion system.

Critical Timing Considerations for EV Rustproofing

New Electric Vehicles typically receive factory-applied corrosion protection during manufacturing. This initial treatment provides adequate protection for approximately three years, depending on driving conditions and environmental exposure. However, this factory protection gradually degrades through normal use, leaving critical components increasingly vulnerable.

Established Electric Vehicles beyond the three-year threshold require immediate attention. Once factory protection deteriorates, rust formation accelerates rapidly, particularly in concealed areas where moisture accumulates without adequate drainage. These "rust nests" create persistent corrosion problems that prove difficult and expensive to address once established.

The optimal timing for professional rustproofing occurs during warmer, drier months when application conditions ensure maximum product penetration and curing effectiveness. Spring and summer appointments typically deliver superior long-term protection compared to winter applications.

Manufacturer Warranty Considerations

Before proceeding with rustproofing treatments, EV owners must carefully review manufacturer warranty terms. Some automotive manufacturers specifically discourage or prohibit certain rustproofing applications due to potential interactions with high-voltage electrical systems.

The primary concern centres on chemical compatibility with electrical insulation, battery housing seals, and sensitive electronic components. Inappropriate rustproofing products or application techniques can potentially damage these critical systems, resulting in warranty voidance and expensive repair costs.

However, professional rustproofing specialists experienced with electric vehicle systems understand these limitations and employ appropriate techniques to avoid sensitive areas while maintaining comprehensive protection. Selecting qualified providers ensures warranty compliance while delivering effective corrosion prevention.

The Professional EV Rustproofing Process

Professional rustproofing for electric vehicles follows a meticulous process designed to accommodate electrical system requirements while delivering comprehensive protection:

Comprehensive Inspection begins every treatment, identifying existing corrosion, vulnerable areas, and electrical components requiring special consideration. This detailed assessment ensures appropriate product selection and application techniques for each specific vehicle.

Thorough Preparation includes complete undercarriage cleaning, removing road salt, debris, and existing loose corrosion. This preparation phase proves critical for optimal product adhesion and long-term effectiveness.

Strategic Application involves carefully applying corrosion-resistant products to steel components while avoiding electrical connections, battery housing, and sensitive sensors. Professional-grade cavity waxes penetrate concealed areas where moisture typically accumulates.

Quality Assurance includes post-application inspection and documentation, ensuring complete coverage while maintaining electrical system integrity.

Rustproofing Benefits Specific to Electric Vehicles

Electric vehicle rustproofing delivers several advantages beyond traditional corrosion prevention:

Electrical System Protection prevents moisture infiltration that could compromise battery performance, charging efficiency, or electronic component function. This protection proves particularly valuable given the high replacement costs of EV-specific electrical systems.

Resale Value Preservation maintains structural integrity and component condition, supporting higher resale values. Well-maintained EVs with comprehensive rust prevention command premium prices in the secondary market.

Extended Component Lifespan reduces premature replacement of expensive suspension, chassis, and mounting components. This longevity proves especially valuable for EVs, where specialised parts often carry premium pricing.

Reduced Maintenance Costs prevents costly rust-related repairs that could otherwise compromise vehicle safety and performance. Proactive protection delivers significant long-term cost savings compared to reactive repair strategies.

Environmental Factors Affecting EV Rust Formation

UK driving conditions present particular challenges for electric vehicle corrosion protection. Road salt application during winter months creates aggressive corrosive environments that accelerate rust formation on unprotected steel components.

Coastal environments introduce additional salt exposure through sea air, while urban driving subjects vehicles to industrial pollutants and road chemicals that compound corrosion risks. These environmental factors affect EVs identically to conventional vehicles, necessitating equivalent protection strategies.

Regular exposure to car washes, particularly those utilising recycled water systems, can introduce additional corrosive contaminants. Professional rustproofing creates protective barriers that resist these environmental challenges while maintaining long-term effectiveness.

Maintenance Requirements After Rustproofing

Professional rustproofing treatments typically require renewal every 12-36 months, depending on driving conditions, environmental exposure, and product selection. This maintenance schedule ensures continuous protection while accommodating natural product degradation over time.

Regular inspection appointments allow professionals to assess treatment effectiveness, identify areas requiring additional attention, and maintain optimal protection levels. These proactive maintenance strategies prevent rust formation while extending overall vehicle lifespan.

Vehicle washing and cleaning practices require minimal modification after professional rustproofing. Most quality treatments withstand normal washing procedures, though pressure washing directly onto electrical components should always be avoided regardless of rustproofing status.

Long-Term Value Protection for Electric Vehicle Investment

Electric vehicles represent significant financial investments that warrant comprehensive protection strategies. Professional rustproofing forms an essential component of this protection, safeguarding both structural integrity and electrical system reliability.

The cost of professional rustproofing proves minimal compared to potential rust-related repair expenses, particularly when electrical system damage occurs. This preventive investment delivers exceptional value through reduced maintenance costs, preserved resale values, and extended component lifespan.

Quality rustproofing treatments provide lifetime protection when properly maintained, ensuring your electric vehicle investment remains secure throughout ownership. This long-term approach proves especially valuable for EVs, where component replacement costs often exceed those of conventional vehicles.

Protect Your Electric Vehicle Investment with Professional Rustproofing

Don't let rust compromise your electric vehicle's performance, safety, or value. At Rustec, our specialist technicians understand the unique requirements of electric vehicle rustproofing, ensuring comprehensive protection while maintaining manufacturer warranty compliance.

Our Life Long Dinitrol® treatment provides premium corrosion protection specifically designed for modern electric vehicles. We meticulously mask sensitive electrical components while delivering thorough coverage to all vulnerable steel surfaces.

Book your comprehensive rustproofing assessment today and discover how professional corrosion protection can extend your EV's lifespan while preserving its investment value. Our expert team provides detailed consultation, transparent pricing, and our industry-leading Rustec Guarantee for complete peace of mind.

Contact Rustec today to schedule your electric vehicle rustproofing assessment and ensure your investment remains protected for years to come.

Comments