Can you rustproof over stone chip?

- Lloyd Saunders

- Nov 22, 2025

- 5 min read

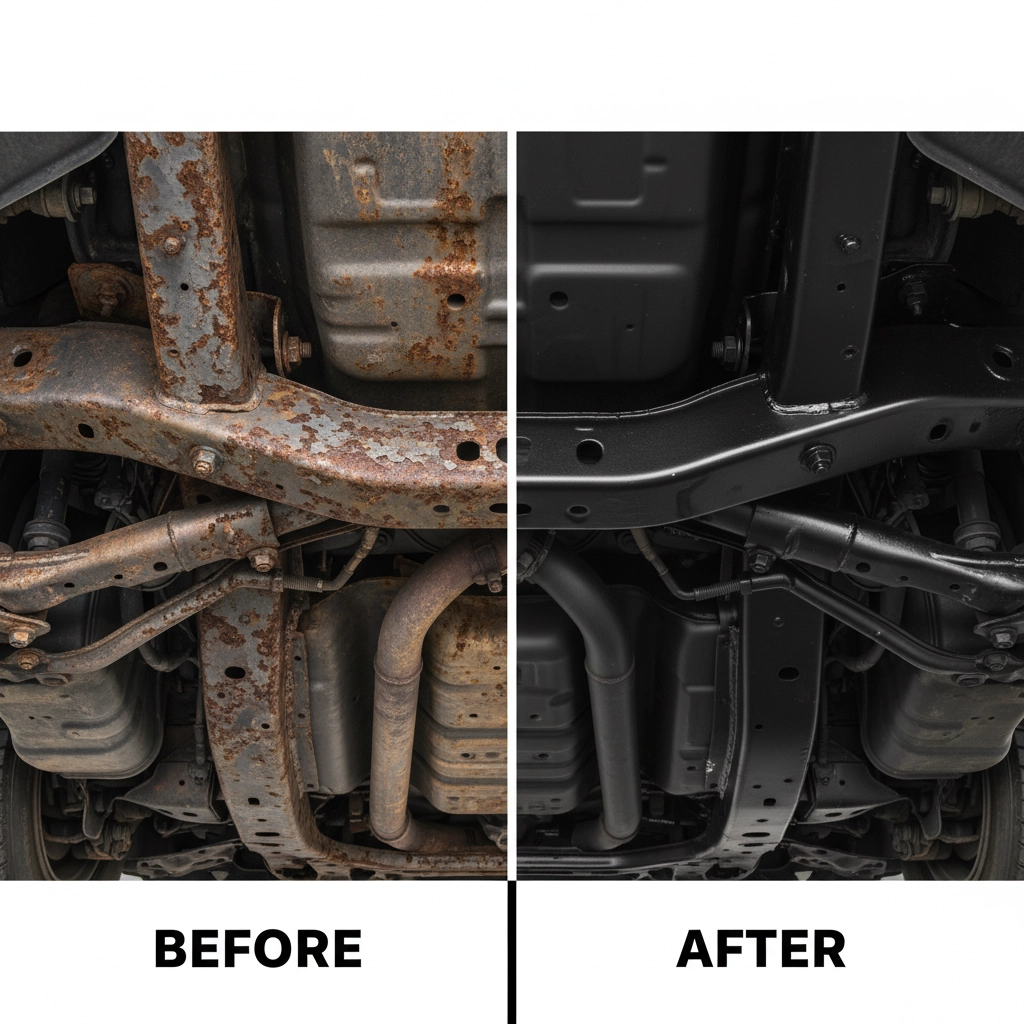

Stone chips are one of the most common threats to your vehicle's long-term protection against corrosion. These small but potentially devastating impacts expose bare metal to the elements, creating perfect entry points for rust formation. The question many vehicle owners face is whether they can apply rustproofing directly over existing stone chip damage, and the answer requires understanding both the science behind corrosion protection and proper surface preparation techniques.

Understanding Stone Chip Damage

Stone chips occur when road debris, gravel, or other projectiles strike your vehicle's surface at high velocity, penetrating through the paint layers to expose the underlying metal substrate. Unlike surface scratches that may only affect the clear coat, stone chips typically penetrate completely through all protective layers, creating direct pathways for moisture, oxygen, and road salt to reach vulnerable steel components.

The exposed metal in a stone chip begins oxidising immediately upon contact with air and moisture. In the UK's particularly challenging climate, with frequent rainfall, high humidity, and extensive winter salt application, this oxidation process accelerates rapidly. Without proper intervention, what begins as a minor cosmetic issue can develop into significant structural corrosion within months.

Can You Apply Rustproofing Over Stone Chips?

Yes, you can rustproof over stone chips, but success depends entirely on proper surface preparation and using appropriate products designed for this specific application. The key principle is that any rustproofing system is only as effective as the surface preparation beneath it. Simply applying standard rustproofing products over unprepared stone chip damage will not provide adequate long-term protection.

The effectiveness of rustproofing over stone chips depends on three critical factors: the current condition of the exposed metal, the quality of surface preparation, and the selection of appropriate protection products. Each of these elements must be addressed methodically to ensure comprehensive corrosion protection.

Surface Preparation: The Foundation of Success

Clean Stone Chip Assessment

Before applying any rustproofing products, conduct a thorough inspection of all stone chip damage. Clean stone chips that expose bare metal but show no signs of rust formation represent the ideal scenario for rustproofing application. These areas require thorough cleaning with automotive degreaser followed by alcohol or white spirit to remove all contaminants, road film, and residual substances that could compromise adhesion.

Rust Treatment Requirements

If rust formation has already begun within the stone chip: evidenced by brown, orange, or red discolouration: you must address this corrosion before applying any protective coatings. Never apply rustproofing over active rust without proper treatment, as the corrosion will continue spreading beneath the coating, potentially causing more extensive damage.

For rust treatment, avoid using sandpaper or abrasive methods on localised stone chip areas, as these can enlarge the damaged area unnecessarily. Instead, apply a high-quality rust converter or rust remover specifically designed for automotive applications. Rust converters transform existing rust into a stable, paintable substrate, while rust removers dissolve rust completely, leaving clean metal ready for protection.

Professional-Grade Products for Stone Chip Protection

Specialised Stone Chip Coatings

Products like DINITROL Stone Chip are specifically formulated to protect exposed metal in stone chip damage while providing excellent adhesion and flexibility. These specialised coatings create a durable barrier that prevents moisture ingress while accommodating the thermal expansion and contraction that occurs in automotive applications.

Cavity Wax Integration

For comprehensive protection, stone chip treatment should be integrated with broader cavity wax application. DINITROL ML and similar cavity wax products provide excellent creepage and penetration properties, ensuring protection extends beyond the immediate stone chip area to surrounding vulnerable zones.

Anti-Stone Chip Aerosols

High-quality anti-stone chip aerosols offer convenient application for DIY enthusiasts while providing professional-level protection. These products typically dry to a hard, rubbery finish that can be overpainted if required, making them suitable for both concealed and visible applications.

Application Methodology

Step-by-Step Process

01: Comprehensive Inspection Identify all stone chip damage across the vehicle, paying particular attention to high-impact zones including the front bumper, bonnet edge, door edges, wheel arches, and lower panels.

02: Surface Preparation Clean all damaged areas thoroughly, removing dirt, wax, and contaminants. Treat any rust formation with appropriate rust converter or remover products.

03: Product Selection Choose rustproofing products specifically designed for stone chip protection, ensuring compatibility with your vehicle's existing coatings and intended use requirements.

04: Application Technique Apply products according to manufacturer specifications, ensuring complete coverage of exposed metal while avoiding over-application that could compromise appearance or function.

05: Curing and Finishing Allow proper curing time before exposing treated areas to washing or harsh environmental conditions. Consider topcoat application where appropriate for colour matching and additional protection.

Professional vs DIY Considerations

Professional Treatment Advantages

Professional rustproofing specialists possess the expertise, equipment, and premium products necessary to address stone chip damage comprehensively. Professional treatment typically includes thorough underbody inspection, proper surface preparation, and application of commercial-grade products not available to consumers. Additionally, professional services often include guarantees and follow-up inspections to ensure long-term effectiveness.

DIY Approach Requirements

Successful DIY stone chip rustproofing requires significant preparation, appropriate product selection, and meticulous attention to detail. While consumer-grade products can provide effective protection when properly applied, the lack of professional equipment and expertise may compromise results, particularly for extensive damage or challenging access areas.

Prevention and Long-Term Strategy

Regular Inspection Protocol

Implement a systematic inspection routine to identify stone chip damage before rust formation begins. Monthly underbody inspections, particularly after winter months or extensive motorway driving, can identify problems while they remain easily treatable.

Preventive Measures

Consider installing paint protection film or stone chip guards on high-impact areas of frequently driven vehicles. These preventive measures, while requiring initial investment, can eliminate the need for remedial stone chip treatment entirely.

Maintenance Schedule

Establish a regular maintenance schedule for rustproofing renewal, particularly for vehicles subjected to harsh operating conditions. Annual inspection and touch-up of stone chip protection ensures continued effectiveness throughout the vehicle's operational life.

Common Mistakes to Avoid

Inadequate Surface Preparation

The most frequent cause of rustproofing failure over stone chips is insufficient surface preparation. Attempting to apply protective coatings over contaminated, rusty, or poorly prepared surfaces invariably leads to premature coating failure and continued corrosion.

Wrong Product Selection

Using general-purpose rustproofing products instead of specialised stone chip coatings often results in poor adhesion, inadequate flexibility, and premature failure. Product selection must match the specific requirements of stone chip protection.

Ignoring Environmental Factors

Applying rustproofing in inappropriate weather conditions: such as high humidity, extreme temperatures, or imminent precipitation: can compromise curing and long-term performance.

Long-Term Value and Protection

Proper stone chip rustproofing represents excellent value for money when compared to the cost of repairing extensive corrosion damage. Early intervention with appropriate products and techniques can prevent thousands of pounds in future repair costs while maintaining vehicle structural integrity and resale value.

The investment in comprehensive stone chip protection pays dividends throughout your vehicle's operational life, particularly for commercial vehicles, 4x4s, and other vehicles subjected to challenging operating conditions.

For vehicle owners seeking professional stone chip rustproofing services, Rustec provides comprehensive inspection, treatment, and protection services using premium Life Long Dinitrol® products. Our meticulous approach ensures your vehicle receives the highest standard of corrosion protection, backed by our comprehensive guarantee and ongoing support.

Whether addressing existing stone chip damage or implementing preventive protection strategies, proper rustproofing over stone chips is not only possible but essential for long-term vehicle protection in the UK's challenging environmental conditions.

Comments