Can you rustproof a car with rust already present?

- Lloyd Saunders

- Dec 30, 2025

- 5 min read

Yes, you can rustproof a car with existing rust present, but success depends entirely on the severity and type of corrosion. This is one of the most frequently asked questions we receive at Rustec, and the answer provides hope for many vehicle owners who've discovered rust on their pride and joy.

The key distinction lies between surface rust and structural corrosion. Understanding this difference will determine whether your vehicle can benefit from professional rustproofing treatment or requires more extensive remedial work first.

When Rustproofing Over Existing Rust Works

Surface Rust: The Green Light

Surface rust presents an ideal candidate for rustproofing treatment. This type of corrosion appears as light brown or reddish discoloration on metal surfaces but hasn't penetrated through the steel substrate. Premium rustproofing products like Dinitrol can be applied directly to surface rust, where they penetrate the corrosion and seal it down to the underlying metal, effectively eliminating moisture access and halting further deterioration.

Most vehicles over three years old exhibit some degree of surface rust, particularly in areas exposed to road salt, moisture, and debris. This is perfectly normal and presents no barrier to effective rustproofing. In fact, treating surface rust promptly prevents it from developing into structural problems that could compromise your vehicle's integrity and MOT compliance.

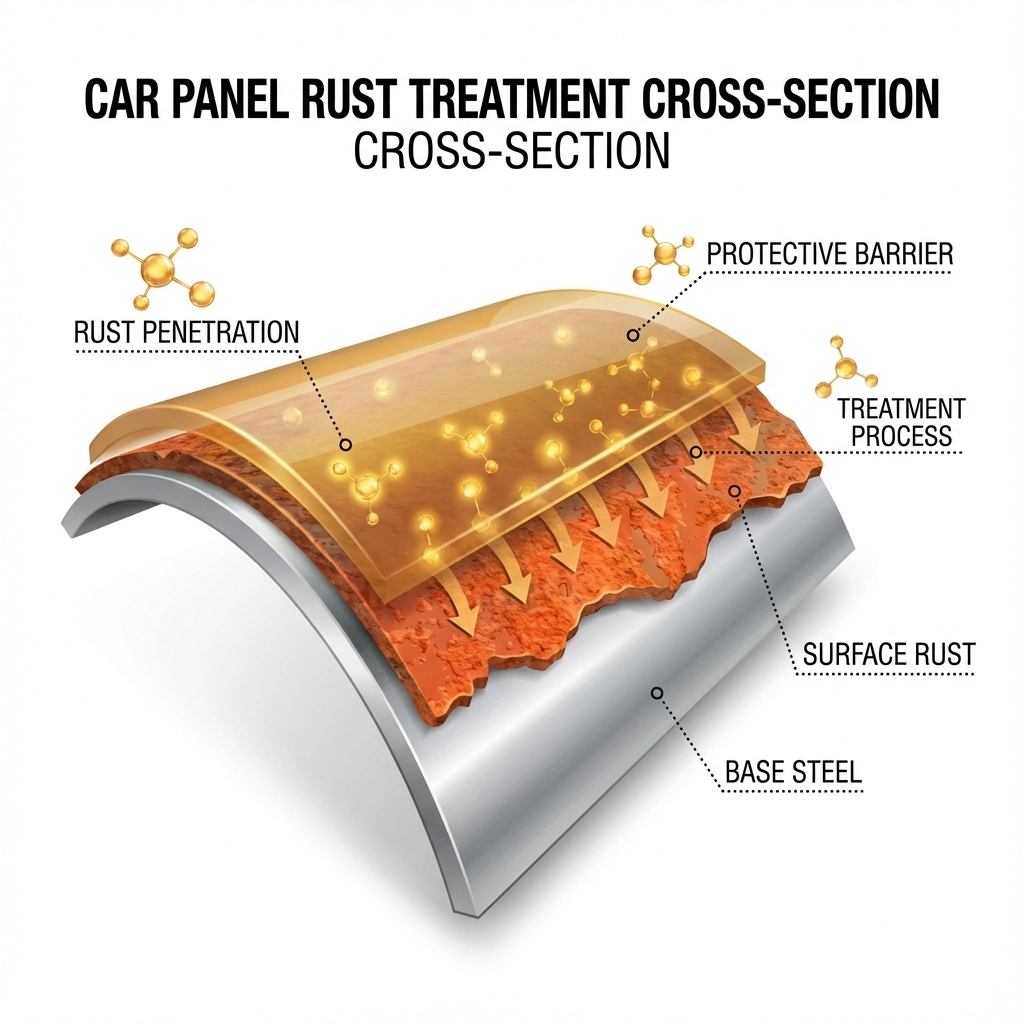

The Science Behind Direct-to-Rust Application

Modern rustproofing formulations are specifically engineered for direct-to-rust application. Dinitrol products utilise advanced penetrating oils that soak deep into surface corrosion, displacing moisture and creating an impermeable barrier. This process doesn't merely cover the rust – it chemically bonds with it, transforming the affected area into a stable, protected surface.

The treatment works by:

Penetrating existing rust layers to reach sound metal beneath

Displacing trapped moisture that fuels ongoing corrosion

Creating a permanent protective film that prevents future oxidation

Sealing micro-pores in the metal surface that could harbour corrosion

When Rustproofing Cannot Proceed

Structural Corrosion: The Red Line

Rustproofing becomes ineffective when rust has compromised the structural integrity of metal components. Several warning signs indicate that rust has progressed beyond the point where protective treatments can help:

Perforation and Through-Rust: When corrosion has eaten completely through metal panels, creating holes or a "Swiss cheese" effect, there's simply nothing left to protect. Once iron in steel is oxidized and lost, no treatment can restore that missing material.

Paint Bubbling and Blistering: Bubbled paint typically indicates aggressive rust activity beneath the surface. This suggests the corrosion has progressed beyond surface level and is actively undermining the metal substrate.

Structural Weakness: If rust has weakened chassis rails, suspension mounting points, or other critical components to the point where they flex or show signs of failure, immediate repair takes priority over protection.

Assessment and Preparation Requirements

For vehicles with existing rust, professional assessment determines the appropriate course of action. Our comprehensive inspection process evaluates:

Extent of surface versus structural corrosion

Thickness of remaining sound metal

Location and severity of affected areas

Overall structural integrity

In cases where rust has caused blistering or localised severe corrosion, preparation work may be required before rustproofing can proceed. This involves removing loose corrosion products and blisters to reach solid substrate, ensuring the protective treatment bonds properly with sound metal.

The Rustproofing Process for Previously Affected Vehicles

Thorough Cleaning and Preparation

Every rustproofing treatment begins with meticulous preparation, particularly crucial for vehicles with existing rust. Our process includes:

Complete undercarriage steam cleaning removes accumulated dirt, salt, and debris that could interfere with product adhesion. High-pressure washing eliminates loose corrosion products while preserving sound metal and existing protective coatings.

Detailed inspection identifies all affected areas and determines the appropriate treatment approach for each zone. Photo documentation provides before-and-after evidence of treatment effectiveness.

Application Techniques for Compromised Surfaces

Direct-to-rust application requires specific techniques to ensure maximum effectiveness:

Pressure Application: Using professional spray equipment, rustproofing products are applied under controlled pressure to ensure deep penetration into affected areas. This technique forces protective oils into crevices and micro-fissures where moisture typically accumulates.

Multiple Coat System: Areas with existing rust often benefit from sequential treatment applications, allowing each layer to penetrate and cure before applying additional protection.

Cavity Treatment: Special attention focuses on enclosed sections and cavity areas where rust often develops undetected. Long-reach application equipment ensures comprehensive coverage in areas inaccessible during normal maintenance.

Product Selection for Rust-Affected Vehicles

Dinitrol ML: The Rust Penetrator

Dinitrol ML stands as the premium choice for treating existing rust due to its exceptional penetrating properties. This honey-coloured, waxy protection remains active for decades, continuously self-healing and maintaining protection even when minor surface damage occurs.

Key advantages for rust-affected vehicles:

Deep penetration into existing corrosion

Displacement of trapped moisture

Self-healing properties that maintain protection over time

Compatibility with existing protective coatings

Comprehensive Treatment Systems

Effective rustproofing of previously affected vehicles requires a systematic approach addressing different areas with appropriate products:

Chassis and Structural Components: Heavy-duty protection using Dinitrol 4941 black wax provides robust, long-lasting protection for critical structural areas.

Cavity Protection: Dinitrol ML cavity wax reaches inaccessible areas through existing drainage holes and access points, providing comprehensive internal protection.

Exposed Surfaces: Clear protective films maintain the appearance of visible components while providing effective corrosion resistance.

Long-Term Effectiveness and Guarantees

Proven Track Record

Our experience treating thousands of rust-affected vehicles demonstrates exceptional long-term results when appropriate products and techniques are employed. Vehicles treated with Life Long Dinitrol® show remarkable transformation, with active rust progression completely halted and protected surfaces remaining stable for decades.

Photo documentation from vehicles treated 10+ years ago reveals surfaces that remain in excellent condition, with original rust areas completely stabilised and no new corrosion development in treated zones.

The Rustec Guarantee

We stand behind our treatments with comprehensive guarantees because we understand the effectiveness of proper rustproofing application. Our warranty covers:

Complete halt of rust progression in treated areas

Long-term protection against new corrosion development

Professional application standards ensuring optimal product performance

Making the Decision: Assessment and Action

Professional Evaluation

Don't let existing rust discourage you from seeking protection – many vehicles with surface corrosion benefit tremendously from professional rustproofing. Our expert assessment determines exactly what's possible for your specific situation.

Free inspection and quotation provides detailed analysis of your vehicle's condition and recommended treatment approach. No obligation consultation ensures you have complete information before making decisions about protection.

Timing Considerations

Acting promptly when rust is discovered maximises treatment effectiveness. Surface rust that's addressed quickly responds excellently to rustproofing, while delayed action allows progression to more serious structural issues requiring extensive remedial work.

Seasonal timing also affects results – treatments applied during dry conditions allow optimal curing and bonding, ensuring maximum long-term effectiveness.

Investment Protection and Value

Cost-Effectiveness Analysis

Rustproofing rust-affected vehicles often proves far more economical than allowing corrosion to progress to the point requiring welding, panel replacement, or chassis repair. Early intervention preserves structural integrity and maintains vehicle value effectively.

Professional rustproofing costs represent a fraction of potential repair bills for advanced corrosion damage. Investment in quality protection typically pays for itself many times over through avoided repair costs and maintained resale value.

Resale Value Preservation

Vehicles with professionally treated rust show significantly higher resale values compared to those where corrosion has been allowed to progress. Documented treatment history provides buyers with confidence in the vehicle's long-term condition and ongoing protection.

Our official treatment service booklet provides permanent record of work completed, raising the resale value of your vehicle and demonstrating commitment to proper maintenance.

The answer is definitively yes – you can successfully rustproof a car with existing rust, provided the corrosion hasn't progressed to structural compromise. Professional assessment, quality products, and expert application combine to halt rust progression and provide decades of ongoing protection.

Don't let existing surface rust prevent you from protecting your investment. Contact Rustec today for comprehensive evaluation and discover how Life Long Dinitrol® protection can transform your vehicle's condition and ensure rust-free motoring for years to come.

Comments