Can you mix Lanoguard with Dinitrol?

- Lloyd Saunders

- Nov 13, 2025

- 4 min read

The short answer is no – you should not mix Lanoguard with Dinitrol. While both are excellent rustproofing products in their own right, combining different chemical formulations can lead to compatibility issues, reduced effectiveness, and potential application problems that could compromise your vehicle's rust protection.

Understanding the Chemistry Behind Rustproofing Products

Lanoguard and Dinitrol represent two distinct approaches to rust prevention, each with carefully engineered chemical compositions designed to work as complete systems. Lanoguard is a lanolin-based product that creates a natural, self-healing barrier, while Dinitrol encompasses a range of synthetic rustproofing compounds including cavity waxes, penetrating oils, and protective coatings.

When different chemical formulations are mixed, unpredictable reactions can occur. These reactions might not be immediately visible but could manifest as:

Separation of active ingredients

Reduced adhesion to metal surfaces

Compromised penetration properties

Inconsistent coverage and protection

Potential for accelerated product degradation

Why Product Purity Matters in Professional Rustproofing

Professional rustproofing relies on proven formulations that have undergone extensive testing. Each manufacturer develops their products to work optimally as standalone solutions, with specific viscosity, penetration characteristics, and curing properties. Mixing products essentially creates an untested compound with unknown performance characteristics.

Dinitrol's range includes products like ML cavity wax, 4941 penetrating compound, and various protective coatings, each formulated for specific applications and substrate conditions. Similarly, Lanoguard's lanolin-based formula has been refined to provide optimal coverage and longevity. Combining these systems compromises the integrity of both formulations.

The Risks of Mixing Rustproofing Products

Chemical Incompatibility

Different rustproofing products contain various additives, solvents, and base materials that may not be compatible when combined. Mixing can result in:

Thickening or thinning beyond optimal application viscosity

Separation of active ingredients during storage or application

Reduced effectiveness of protective compounds

Application difficulties including clogged spray equipment

Warranty Implications

Most professional rustproofing services offer guarantees on their work, but these warranties typically specify the use of approved products in their original formulations. Mixing different brands or types of rustproofing materials could void any warranty protection, leaving you financially exposed if rust problems develop.

Equipment Damage

Mixing incompatible products can cause issues with application equipment. Professional spray systems are calibrated for specific product viscosities and chemical properties. Unknown mixtures can clog nozzles, damage seals, or require extensive equipment cleaning between applications.

Individual Strengths of Lanoguard and Dinitrol

Lanoguard Benefits

Lanoguard's lanolin-based formula offers several distinct advantages:

Self-healing properties where minor scratches in the coating naturally close over time

Environmental friendliness as a naturally-derived product

Excellent penetration into existing rust and crevices

Long-lasting protection with gradual migration to provide ongoing coverage

Dinitrol Advantages

Dinitrol products provide comprehensive rust prevention through:

Cavity wax systems that specifically target hard-to-reach internal structures

Penetrating compounds designed for active rust treatment

Flexible coatings that move with vehicle components without cracking

Professional-grade formulations used by commercial fleets and military applications

Professional Application: The Right Product for the Right Job

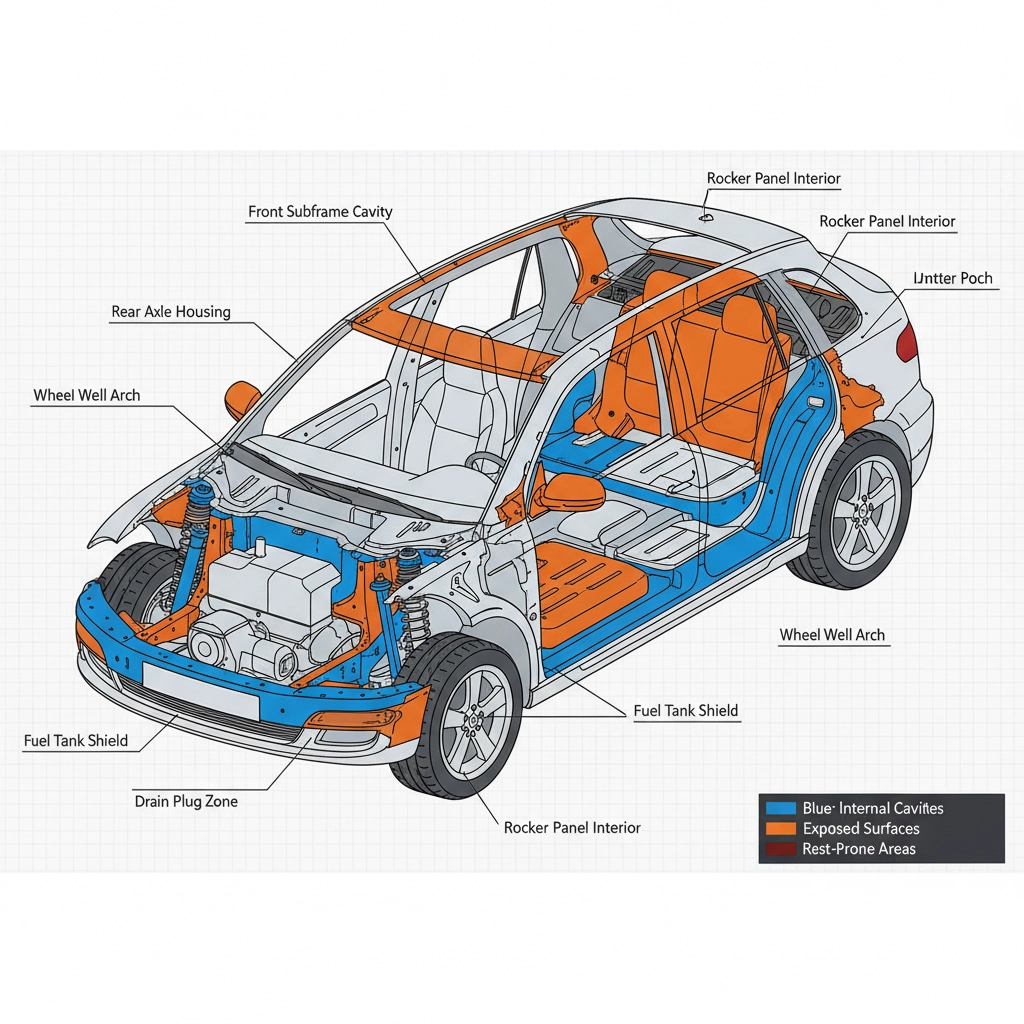

Rather than mixing products, professional rustproofing follows a systematic approach using complementary products in sequence. A comprehensive rustproofing treatment might involve:

Phase 1: Preparation and Cleaning

Thorough undercarriage steam cleaning

Rust assessment and minor repair

Masking of sensitive components

Phase 2: Targeted Treatment

Cavity wax injection for internal structures

Penetrating compound for existing rust areas

Protective coating for exposed surfaces

Phase 3: Final Protection

Complete undercarriage coating application

Quality inspection and documentation

Customer handover with maintenance guidance

This methodical approach ensures each product is applied where it performs best, rather than compromising effectiveness through mixing.

When Different Products Can Work Together

While mixing is not recommended, using different rustproofing products in sequence can be highly effective. Professional applications often involve:

Cavity wax for internal box sections and door frames

Penetrating oil for existing rust areas and hard-to-reach spots

Protective coating for general undercarriage surfaces

Specific treatments for different materials and exposure conditions

The key is applying each product where it performs optimally, allowing proper curing times between applications, and ensuring compatibility when products might overlap.

DIY Considerations and Professional Recommendations

If you're considering DIY rustproofing, resist the temptation to mix products thinking you'll get "the best of both worlds." Instead:

Choose one primary system and apply it according to manufacturer instructions. Whether you select Lanoguard, Dinitrol, or another quality brand, consistent application of a proven formulation will deliver better results than mixing different products.

Consider professional application for optimal results. Professional rustproofing services have the experience, equipment, and product knowledge to deliver comprehensive protection using proven methods and materials.

The Rustec Approach to Comprehensive Protection

At Rustec, we understand the science behind effective rust prevention. Our comprehensive rustproofing services use proven product combinations applied in the correct sequence for maximum protection. We don't experiment with untested mixtures – instead, we rely on professional-grade materials applied with precision and expertise.

Our approach includes:

Detailed pre-treatment inspection to identify specific protection requirements

Professional product selection based on vehicle type and usage patterns

Systematic application using calibrated equipment and proven techniques

Quality assurance with photographic documentation of all work completed

Ongoing support with maintenance advice and reapplication services

Rather than risk compatibility issues by mixing different products, trust your vehicle's protection to professionals who understand how to achieve optimal results using proven methods and materials.

Making the Right Choice for Your Vehicle

The question of mixing Lanoguard with Dinitrol highlights a common misconception that more products equal better protection. In reality, professional rust prevention relies on using the right products in the right way, not on creating untested combinations.

Whether you choose Lanoguard, Dinitrol, or another quality rustproofing system, commit to that choice and apply it properly. For comprehensive protection that you can trust, consider professional application where product selection, preparation, and application technique all contribute to long-lasting rust prevention.

Ready to protect your vehicle with professional rustproofing? Contact Rustec today for expert advice on the best rust prevention approach for your specific vehicle and driving conditions. Our experienced team will recommend the optimal products and application methods to keep your vehicle rust-free for years to come, without the risks associated with mixing incompatible formulations.

Comments