Can you combine Lanoguard with Dinitrol?

- Lloyd Saunders

- 6 days ago

- 5 min read

When it comes to premium rustproofing solutions, two names consistently emerge as industry leaders: Lanoguard and Dinitrol. Both products have earned their reputation through decades of proven performance in protecting vehicles from the UK's harsh environmental conditions. However, many vehicle owners find themselves asking whether these two exceptional products can work together to provide even greater protection.

The short answer is yes, but with important considerations regarding application methodology, compatibility, and optimal performance outcomes.

Understanding Lanoguard and Dinitrol Technologies

Before exploring combination strategies, it's essential to understand the fundamental differences between these two rustproofing systems.

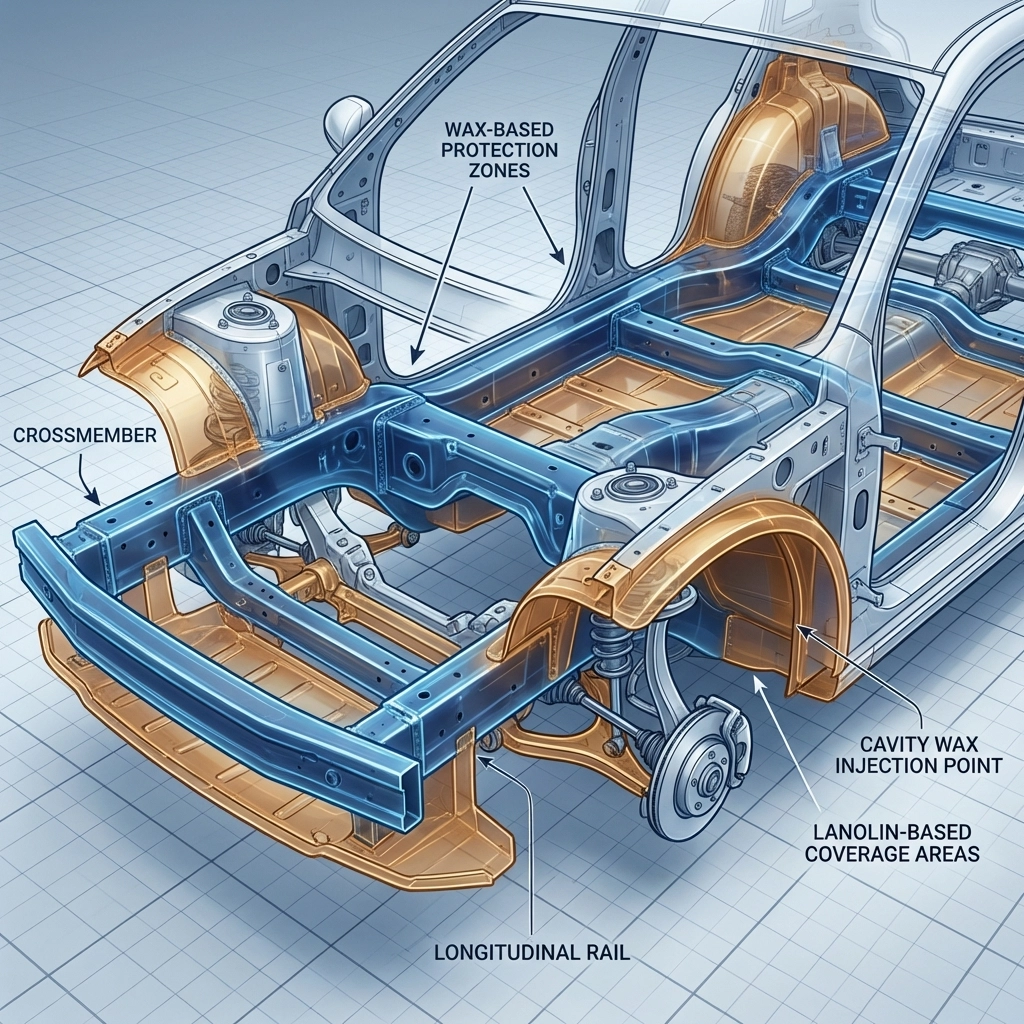

Lanoguard is a lanolin-based, penetrating rust prevention compound that creates a flexible, self-healing barrier. Its bio-friendly formulation makes it particularly suitable for comprehensive vehicle coverage, including sensitive areas around rubber seals, electronics, and painted surfaces. Lanoguard's molecular structure allows it to penetrate existing corrosion and displace moisture whilst forming a protective film.

Dinitrol, specifically the ML (Cavity Wax) variant, represents German engineering excellence in corrosion protection. This wax-based system provides exceptional long-term protection through its ability to remain active and migrate into microscopic crevices. Dinitrol products are formulated for specific applications, with different variants designed for various vehicle areas and protection requirements.

Professional Application Strategies: Zone-Based Protection

The most effective approach to combining Lanoguard and Dinitrol involves strategic zone-based application rather than direct layering. This methodology maximises each product's strengths whilst ensuring optimal adhesion and performance.

Internal Cavity Protection with Dinitrol ML

Dinitrol ML excels in enclosed spaces such as:

Box sections and chassis rails

Door frames and pillars

Internal wing structures

Sill cavities

Tailgate and bonnet frameworks

The penetrating properties and long-term stability of Dinitrol ML make it the premium choice for these hard-to-reach areas where moisture typically accumulates and corrosion begins.

External Surface Protection with Lanoguard

Lanoguard demonstrates superior performance on exposed surfaces including:

Undercarriage components

Suspension assemblies

Brake lines and fuel lines

Exhaust system mounting points

Visible chassis elements

This zone-based approach ensures each product performs optimally within its designed parameters whilst providing comprehensive vehicle protection.

Compatibility Considerations and Best Practices

When implementing a combined protection strategy, several critical factors must be considered to ensure maximum effectiveness and longevity.

Surface Preparation Requirements

Thorough surface preparation remains paramount regardless of product choice. Our comprehensive inspection process begins with:

Complete undercarriage steam cleaning to remove existing contaminants

Detailed assessment of existing protection systems

Identification of optimal application zones

Documentation of current condition through photographic evidence

Application Timing and Sequence

Professional application sequence significantly impacts final protection quality:

Initial Cavity Treatment: Dinitrol ML application to internal spaces using precision injection equipment

Curing Period: Allowing adequate time for initial penetration and adhesion

External Coverage: Lanoguard application to exposed surfaces using professional spray systems

Quality Verification: Comprehensive inspection to ensure complete coverage

Technical Performance Benefits of Combined Systems

The strategic combination of Lanoguard and Dinitrol creates a multi-layered defence system that addresses various corrosion mechanisms simultaneously.

Enhanced Moisture Displacement

Lanoguard's exceptional moisture displacement properties complement Dinitrol's cavity protection by ensuring surface water cannot penetrate to underlying metal surfaces. This dual-action approach creates an environment where corrosion cannot establish or progress.

Extended Protection Intervals

Professional testing demonstrates that zone-appropriate application of these premium products can extend protection intervals beyond what either product achieves independently. This translates to enhanced value and reduced maintenance requirements over the vehicle's lifetime.

Temperature Stability and Flexibility

Both products maintain their protective properties across the UK's variable climate conditions. Lanoguard's flexibility prevents cracking during temperature fluctuations, whilst Dinitrol's wax base provides stable long-term protection against environmental contamination.

Professional Application vs DIY Considerations

While both Lanoguard and Dinitrol are available for DIY application, professional installation ensures optimal performance and coverage. Our certified technicians possess the expertise, equipment, and experience necessary to:

Accurately assess existing protection systems

Determine optimal product selection for specific vehicle areas

Ensure complete coverage using precision application equipment

Provide documentation and warranty coverage

Equipment Requirements for Effective Application

Professional-grade application requires:

High-pressure spray systems for even Lanoguard coverage

Precision injection equipment for Dinitrol cavity treatment

Proper masking and protection for sensitive components

Environmental controls for optimal curing conditions

Warranty Implications and Quality Assurance

When professionally applied using our proven methodologies, combined Lanoguard and Dinitrol treatments qualify for our comprehensive warranty coverage. This protection encompasses:

Material performance guarantees

Application quality assurance

Annual inspection and touch-up services

Complete documentation and service history

Quality Control Measures

Our quality assurance programme ensures consistent results through:

Pre-treatment condition assessment

Application methodology verification

Post-treatment inspection procedures

Customer satisfaction confirmation

Vehicle-Specific Recommendations

Different vehicle types benefit from customised protection strategies that optimise the Lanoguard and Dinitrol combination.

Commercial Vehicles and 4x4s

Heavy-duty vehicles operating in challenging environments require enhanced protection strategies:

Comprehensive Dinitrol ML cavity treatment for structural integrity

Complete Lanoguard undercarriage coverage for operational component protection

Additional attention to high-stress areas and mounting points

Classic and Specialist Vehicles

Heritage vehicles demand specialised approaches that preserve authenticity whilst providing modern protection:

Careful assessment of existing treatments and materials compatibility

Selective application to maintain original specifications

Enhanced documentation for restoration and insurance purposes

Environmental Considerations and Safety

Both Lanoguard and Dinitrol meet stringent environmental and safety standards, making them suitable for comprehensive vehicle treatment without compromising ecological responsibility.

Bio-Friendly Formulations

Lanoguard's lanolin base provides natural biodegradability whilst maintaining exceptional performance. Dinitrol's formulation ensures minimal environmental impact whilst delivering premium protection capabilities.

Application Safety Protocols

Professional application follows strict safety protocols including:

Proper ventilation and respiratory protection

Environmental containment measures

Waste management procedures

Health and safety compliance verification

Long-Term Maintenance and Care

Maximising the benefits of combined Lanoguard and Dinitrol protection requires appropriate long-term maintenance strategies.

Inspection Intervals

Regular professional inspection ensures continued protection effectiveness:

Annual comprehensive assessment

Identification of wear patterns or damage

Targeted reapplication where necessary

Documentation of protection system condition

Maintenance Best Practices

Vehicle owners can support long-term protection through:

Regular washing to remove contamination

Prompt attention to stone chip damage

Professional inspection following off-road use

Adherence to manufacturer washing and care recommendations

Making the Right Choice for Your Vehicle

The decision to combine Lanoguard and Dinitrol should be based on comprehensive vehicle assessment and specific protection requirements. Our expert consultation process ensures optimal product selection and application strategy for your individual circumstances.

Professional assessment considers:

Vehicle age and current condition

Operating environment and usage patterns

Existing protection systems

Long-term ownership plans

Budget and value considerations

For vehicles requiring maximum protection against the UK's challenging environmental conditions, the strategic combination of Lanoguard and Dinitrol represents the premium solution. Through professional application and ongoing maintenance, this approach delivers unmatched corrosion protection and peace of mind.

Contact our team today to discuss how combined Lanoguard and Dinitrol protection can safeguard your vehicle investment for years to come.

Comments