Can rustproofing be removed?

- Lloyd Saunders

- Nov 22, 2025

- 5 min read

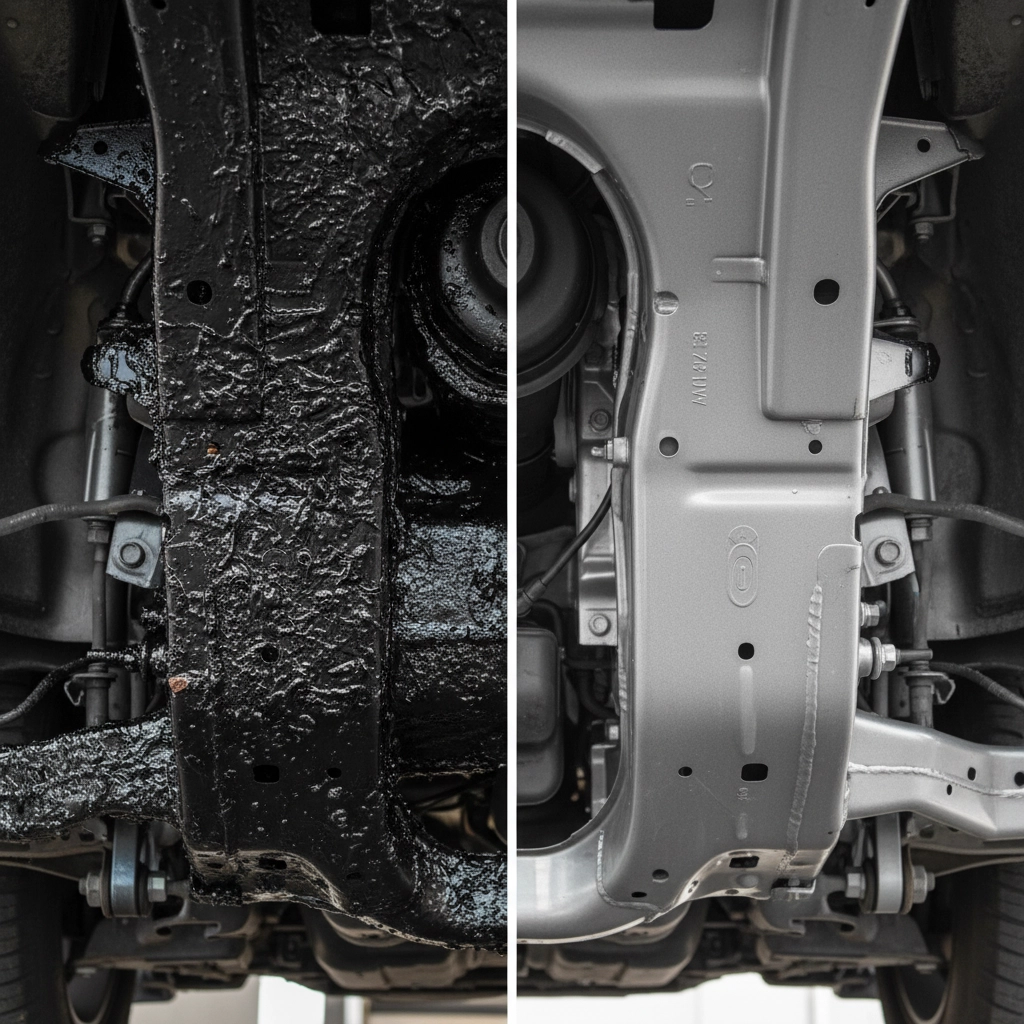

Whether you've discovered poor-quality rustproofing work, need to access specific components, or are preparing your vehicle for a different treatment, rustproofing can indeed be removed. The process requires the right approach, proper materials, and careful execution to avoid damaging your vehicle's paintwork or underlying surfaces.

Why You Might Need to Remove Rustproofing

Several scenarios may necessitate rustproofing removal. Poorly applied treatments that have trapped moisture or debris can actually accelerate corrosion rather than prevent it. Overspray on visible surfaces, wheels, or painted areas creates an unsightly appearance that requires correction. Additionally, certain repairs or modifications may require complete access to chassis components, making removal essential.

Some vehicle owners discover that previous treatments were applied over existing rust without proper preparation, reducing their effectiveness. In these cases, complete removal followed by professional surface preparation and reapplication provides superior long-term protection.

Professional vs DIY Removal Considerations

The complexity of rustproofing removal varies significantly depending on the product type, application method, and coverage area. Modern professional treatments like Life Long Dinitrol® systems are specifically formulated for durability, making removal more challenging than basic wax-based products.

Professional removal services offer several advantages, including proper equipment, ventilation systems, and disposal methods for removed materials. Technicians understand which solvents are compatible with different vehicle systems and can avoid damage to rubber seals, electrical components, and painted surfaces.

DIY removal is possible for minor overspray or limited areas, but extensive removal projects often benefit from professional expertise to ensure complete and safe removal without vehicle damage.

Chemical Removal Methods

Prep Sol stands as the most effective commercial solution for rustproofing removal. This specialized cleaner dissolves most rustproofing products while remaining paint-safe when used correctly. Apply Prep Sol with lint-free cloths, working in small sections to maintain control over the process.

Kerosene offers another paint-safe option, particularly effective for removing lingering residue. Many professional workshops use kerosene as a waterless wash solution to address overspray before proceeding with standard washing procedures. The low volatility of kerosene provides extended working time compared to other solvents.

For stubborn or aged rustproofing, solvent solutions at 30-50% concentration can dissolve and soften hardened coatings. These stronger solutions require careful handling and should be followed with thorough degreasing to remove all residual material.

Cleaner wax works well for removing light residue and overspray from painted surfaces. This method is particularly useful for final cleanup after primary removal using stronger solvents.

Mechanical Removal Techniques

Certain situations may require mechanical assistance alongside chemical methods. Plastic scrapers can help remove softened rustproofing without scratching metal surfaces. Avoid metal tools that could damage chassis components or create areas where future corrosion might initiate.

Pressure washing with heated water can effectively remove loosened material, but requires careful pressure control to avoid forcing contaminants into crevices or damaging sensitive components. Professional steam cleaning provides superior results while maintaining precise control over temperature and pressure.

For heavy accumulations, particularly on older vehicles, professional media blasting may be necessary. This process requires complete masking of sensitive areas and should only be performed by experienced technicians with appropriate facilities.

Safety Considerations During Removal

Rustproofing removal involves potentially hazardous materials requiring proper safety precautions. Always work in well-ventilated areas or outdoors to avoid solvent vapor accumulation. Chemical-resistant gloves protect skin from prolonged solvent contact, while safety glasses prevent splash injuries.

Dispose of removed materials and contaminated cloths according to local environmental regulations. Many rustproofing products contain petroleum derivatives that require special handling. Never pour solvents down drains or onto soil.

Fire safety becomes critical when working with flammable solvents. Remove ignition sources from the work area and keep appropriate fire extinguishers readily accessible. Allow adequate drying time before exposing treated areas to heat sources.

Post-Removal Preparation and Treatment

Complete removal creates an opportunity for superior surface preparation and reapplication. Thoroughly degrease all surfaces using industrial-grade cleaners to ensure complete solvent removal. Any residual chemicals can interfere with new rustproofing adhesion.

Inspect revealed surfaces for corrosion, damage, or wear that may have been hidden beneath the previous treatment. Address any rust through appropriate preparation methods, from wire brushing for surface rust to professional treatment for more significant corrosion.

Allow adequate drying time before applying new rustproofing. Moisture trapped beneath fresh treatments can cause premature failure and accelerated corrosion.

When to Choose Professional Removal Services

Complex removal projects benefit significantly from professional expertise and equipment. Vehicles with extensive rustproofing coverage, particularly in difficult-to-access areas, require specialized tools and techniques that exceed typical DIY capabilities.

Professional services ensure proper disposal of removed materials while maintaining environmental compliance. They also possess the knowledge to identify which removal methods work best for specific rustproofing products without compromising vehicle integrity.

For vehicles requiring complete rustproofing system renewal, professional removal followed by comprehensive reapplication provides the most effective long-term protection. This approach ensures proper surface preparation and application techniques that maximize treatment lifespan.

Alternative Approaches to Complete Removal

In some situations, partial removal or treatment over existing rustproofing may prove more practical. Certain high-quality rustproofing products can accept reapplication without complete removal, provided the existing treatment remains sound and properly adhered.

Surface preparation through cleaning and light abrasion can improve adhesion for new treatments applied over existing rustproofing. This approach works particularly well when the existing treatment provides good coverage but requires refreshing or enhancement.

Professional assessment can determine whether complete removal is necessary or if surface preparation and overcoating will provide adequate protection. This evaluation considers the existing treatment type, condition, and intended new treatment compatibility.

Cost Considerations and Planning

Rustproofing removal costs vary significantly based on coverage area, product type, and removal complexity. DIY removal requires investment in proper solvents, safety equipment, and disposal arrangements, while professional services include all necessary materials and expertise.

Consider the total project cost, including removal, preparation, and reapplication when planning rustproofing renewal. Professional services often provide package pricing that delivers better value than addressing each phase separately.

Factor in vehicle downtime for extensive removal projects. Complex removals may require several days, particularly when followed by comprehensive reapplication of premium rustproofing systems.

Prevention and Maintenance

Proper initial application significantly reduces the likelihood of requiring removal. Choose reputable service providers who understand proper surface preparation, application techniques, and coverage requirements. Quality initial work eliminates most common reasons for rustproofing removal.

Regular maintenance and inspection help identify issues before they necessitate complete removal. Professional assessment services can determine when touch-up work or partial renewal provides adequate protection without extensive removal requirements.

Professional Expertise Makes the Difference

Rustproofing removal, while achievable through various methods, requires careful consideration of safety, effectiveness, and subsequent treatment plans. Professional expertise ensures proper removal without compromising vehicle integrity while providing opportunities for superior long-term protection through comprehensive reapplication.

For complex removal projects or when planning complete rustproofing system renewal, professional services deliver superior results while maintaining safety standards and environmental compliance. The investment in professional removal and reapplication provides enhanced protection and peace of mind for years to come.

Contact our team to discuss your rustproofing removal requirements and explore options for comprehensive protection that keeps your vehicle rust-free for life.

Comments