Can MOT testers fail you for surface rust?

- Lloyd Saunders

- Nov 15, 2025

- 5 min read

The short answer is no – MOT testers cannot fail your vehicle for surface rust alone. Surface corrosion on non-structural areas like doors, bonnet, or roof panels is considered a cosmetic issue and will not result in an MOT failure. However, the distinction between surface rust and structural corrosion is critical to understanding what will and won't pass your annual test.

The MOT (Ministry of Transport) test focuses exclusively on safety, roadworthiness, and environmental standards – not the aesthetic condition of your vehicle. While visible rust may be unsightly and concerning for vehicle value, it only becomes an MOT issue when it compromises the structural integrity or safety-critical components of your car.

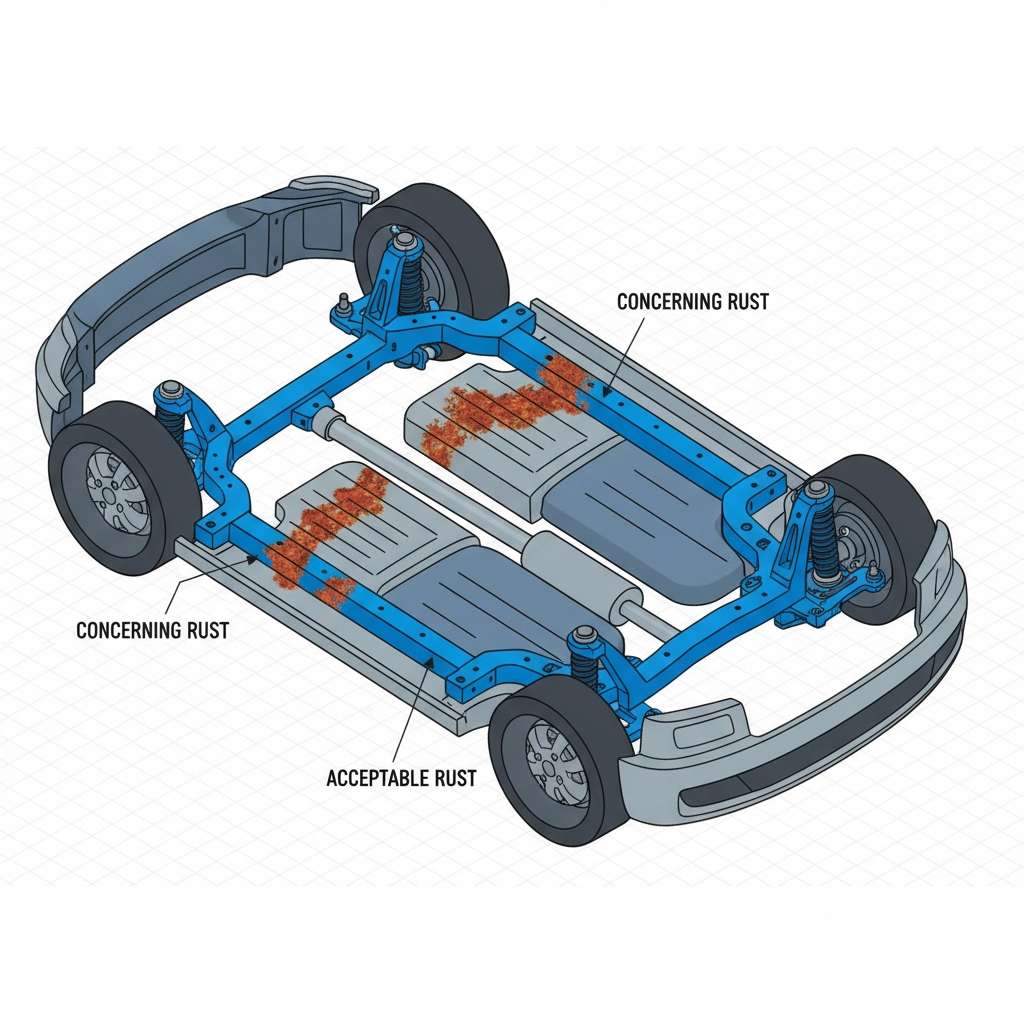

Understanding MOT Rust Assessment Criteria

MOT testers follow strict government guidelines when assessing corrosion during your annual test. According to the official MOT inspection manual, rust in prescribed structural areas only constitutes a failure if it meets specific criteria:

The corrosion has caused a hole in the metal

The affected area does not feel firm when pressed with finger and thumb

A corrosion assessment tool creates a hole when applied to the area

These criteria ensure that only rust which genuinely affects the vehicle's structural integrity or safety will result in a failure. Surface oxidation that hasn't penetrated the metal or weakened load-bearing components will be overlooked during the inspection.

Structural Areas vs Non-Structural Areas

The key to understanding MOT rust failures lies in distinguishing between structural and non-structural areas of your vehicle. Structural components are those that bear loads, provide crash protection, or house safety-critical systems. These include:

Chassis rails and subframes

Sills (door threshold areas)

Suspension mounting points

Seat belt mounting areas

Brake line mounting points

Fuel tank mounting areas

Exhaust system mountings

Load-bearing body panels

Corrosion in these areas will be thoroughly examined, as failure could compromise vehicle safety or roadworthiness. Conversely, non-structural areas include cosmetic panels that don't affect the vehicle's fundamental integrity:

Door skins and outer panels

Bonnet and boot lid surfaces

Roof panels

Wing mirrors and trim pieces

Decorative bodywork elements

Surface rust in these areas, while potentially affecting resale value, poses no safety risk and therefore won't trigger an MOT failure.

How MOT Testers Conduct Rust Inspections

During your MOT test, the examiner will conduct both visual and physical assessments of potentially corroded areas. The inspection process involves:

Visual Examination: The tester will look for obvious signs of corrosion, particularly around welded joints, stress points, and areas prone to water accumulation. They're specifically trained to identify rust that may have compromised structural integrity.

Physical Testing: In areas where corrosion is visible, the examiner will apply finger and thumb pressure to assess whether the metal remains firm. If the area feels soft or flexible, it indicates significant metal loss that could constitute a failure.

Tool Assessment: Where necessary, testers may use specialised corrosion assessment tools – essentially controlled probes – to determine the extent of metal deterioration. If the tool penetrates the metal easily, creating a hole, this would result in a failure.

Common MOT Rust Failure Areas

While surface rust won't fail your MOT, certain areas of vehicles are particularly susceptible to structural corrosion that will cause problems:

Sills: These load-bearing structures run along the bottom edge of your vehicle's body. They're constantly exposed to road spray, salt, and debris, making them highly prone to rust-through. Perforated or significantly weakened sills are among the most common MOT failure reasons.

Subframes: Front and rear subframes carry engine, transmission, and suspension components. Corrosion here affects handling, safety, and structural integrity, making it a priority area for MOT assessment.

Suspension Mountings: These critical attachment points must remain structurally sound to ensure proper suspension geometry and safety. Rust-weakened mounting points can lead to catastrophic failure and immediate MOT rejection.

Brake Components: Any corrosion affecting brake lines, mounting brackets, or structural elements of the braking system will result in failure, as this directly impacts safety.

Areas That Won't Cause MOT Failures

Understanding which rust concerns won't affect your MOT can provide peace of mind:

Cosmetic Body Panels: Surface rust on doors, bonnets, boot lids, and similar non-load-bearing panels is purely aesthetic. While it may reduce your vehicle's value, it poses no safety concern for MOT purposes.

Wheel Arch Linings: Light surface corrosion on wheel arch edges or inner areas typically won't cause failures unless it extends to structural mounting points.

Exhaust System Surface Rust: While the exhaust mounting points are assessed, surface corrosion on the exhaust pipes themselves is expected and acceptable, provided the system remains secure and doesn't leak excessively.

Preparing Your Vehicle for MOT Success

The most effective approach to avoiding rust-related MOT failures is prevention and early intervention. Regular inspection of your vehicle's underside, particularly after winter months when road salt exposure is highest, can identify developing issues before they become serious problems.

Professional Assessment: If you're concerned about rust on your vehicle, a comprehensive pre-MOT inspection by qualified technicians can identify potential failure points. This allows time for necessary repairs or treatments before your official test.

Preventive Treatment: Modern rustproofing systems like Dinitrol provide long-term protection for both new and existing vehicles. These treatments penetrate existing light rust, neutralise further corrosion, and create lasting barriers against future oxidation.

Cavity Protection: Internal body cavities and box sections are particularly vulnerable to hidden corrosion. Professional cavity wax injection ensures these hard-to-reach areas receive adequate protection against moisture and salt ingress.

The Importance of Professional Rust Assessment

While surface rust won't fail your MOT, distinguishing between cosmetic and structural corrosion requires expertise. What appears to be minor surface oxidation may actually indicate more serious underlying issues. Professional assessment provides several advantages:

Expertise: Qualified technicians understand the difference between acceptable surface corrosion and potentially serious structural rust. Their trained eye can spot developing problems that untrained individuals might miss.

Comprehensive Inspection: Professional inspections cover all critical areas systematically, ensuring nothing is overlooked. This includes hard-to-reach areas that casual inspection might miss.

Preventive Solutions: If issues are identified, professionals can recommend appropriate treatments to address existing rust and prevent future corrosion, potentially saving significant repair costs down the line.

Long-Term Vehicle Protection Strategy

The most cost-effective approach to rust management combines prevention, early detection, and professional treatment. Rather than waiting for rust to become an MOT issue, proactive protection maintains your vehicle's structural integrity and value throughout its lifetime.

Annual Inspections: Regular professional assessment, ideally before your MOT test, identifies developing issues while they remain manageable and cost-effective to address.

Quality Treatment Products: Premium rustproofing systems like Dinitrol offer superior protection compared to basic underseal products. These professional-grade treatments provide comprehensive protection for structural areas most critical to MOT compliance.

Ongoing Maintenance: Rustproofing isn't a one-time treatment. Regular reapplication and touch-up work ensures continuing protection, particularly for vehicles operating in challenging conditions with high salt exposure.

Secure Your MOT Success with Professional Pre-Test Inspection

Don't leave your MOT result to chance. While surface rust won't cause a failure, hidden structural corrosion could lead to expensive problems and inconvenient test failures. Our comprehensive pre-MOT rust inspection service identifies potential issues before they become costly problems.

At Rustec, our qualified technicians provide thorough undercarriage assessment using the same criteria applied during official MOT testing. We'll identify any areas of concern, explain the difference between cosmetic and structural issues, and recommend appropriate treatments where necessary.

Book your FREE pre-MOT rust inspection today and gain complete confidence in your vehicle's condition before the official test. Our expert assessment covers all critical structural areas, providing you with detailed documentation of your vehicle's rust status and professional recommendations for any necessary action.

Contact Rustec now to schedule your complimentary inspection and ensure your vehicle passes its MOT first time, every time. Your peace of mind is our guarantee.

Comments