Can MOT testers fail you for covering rust?

- Lloyd Saunders

- 6 days ago

- 4 min read

Vehicle owners across the UK frequently express concern about whether applying protective coatings to their vehicle's underside could result in MOT failure. This comprehensive guide addresses these concerns and provides definitive answers based on official MOT guidelines and professional expertise.

The Fundamental MOT Principle: Assessment Based on Visibility

MOT testers cannot fail your vehicle simply for covering rust with protective coatings. This fundamental principle governs all MOT inspections and provides reassurance for vehicle owners who have invested in professional rustproofing treatments.

The key understanding is that MOT testers can only assess what they can adequately see and examine during the inspection process. When areas are completely covered with underseal, wax, or other protective treatments that prevent proper inspection, examiners typically issue advisories rather than outright failures.

This means that a comprehensive rustproofing treatment using premium products like Dinitrol or Lanoguard will not automatically result in MOT failure. Professional rustproofing services understand MOT requirements and apply treatments accordingly to ensure compliance while maximising protection.

When Protective Coatings Can Create MOT Complications

While MOT testers cannot fail vehicles solely for having covered rust, several scenarios can lead to complications during the inspection process:

Deteriorated Protective Coverings

When protective coatings begin to peel, crack, or deteriorate, they may expose underlying rust that becomes visible to the MOT tester. In these circumstances, the examiner must assess any exposed corrosion according to standard failure criteria. This highlights the importance of maintaining protective treatments and ensuring they remain in optimal condition.

Quality rustproofing products like Life Long Dinitrol® are specifically formulated to provide lasting protection without deterioration, reducing the risk of exposure during MOT inspections. Professional application ensures even coverage and longevity that withstands the demanding UK climate.

Partial Coverage Issues

Rust that remains partially visible during inspection will be evaluated based on standard MOT assessment criteria and may result in failure if it meets the prescribed failure conditions. This scenario often occurs when vehicle owners attempt DIY treatments without comprehensive coverage or professional expertise.

Professional rustproofing services conduct comprehensive inspections before treatment application, ensuring complete coverage of vulnerable areas and eliminating partial protection issues that could lead to MOT complications.

Inspection Obstruction Concerns

If protective coatings prevent proper inspection of safety-critical areas, MOT examiners may issue advisories highlighting potential concerns for future testing. While these advisories do not constitute failures, they serve as important notifications for vehicle owners.

Meticulously applied professional treatments are designed to provide maximum protection while maintaining accessibility for essential MOT inspection points. Expert technicians understand which areas require careful treatment to avoid obstruction issues.

Understanding Actual MOT Failure Criteria for Corrosion

MOT failures related to corrosion are determined by location, extent, and structural impact rather than whether rust is covered. Understanding these criteria helps vehicle owners appreciate how professional rustproofing contributes to MOT success.

Location-Based Assessment

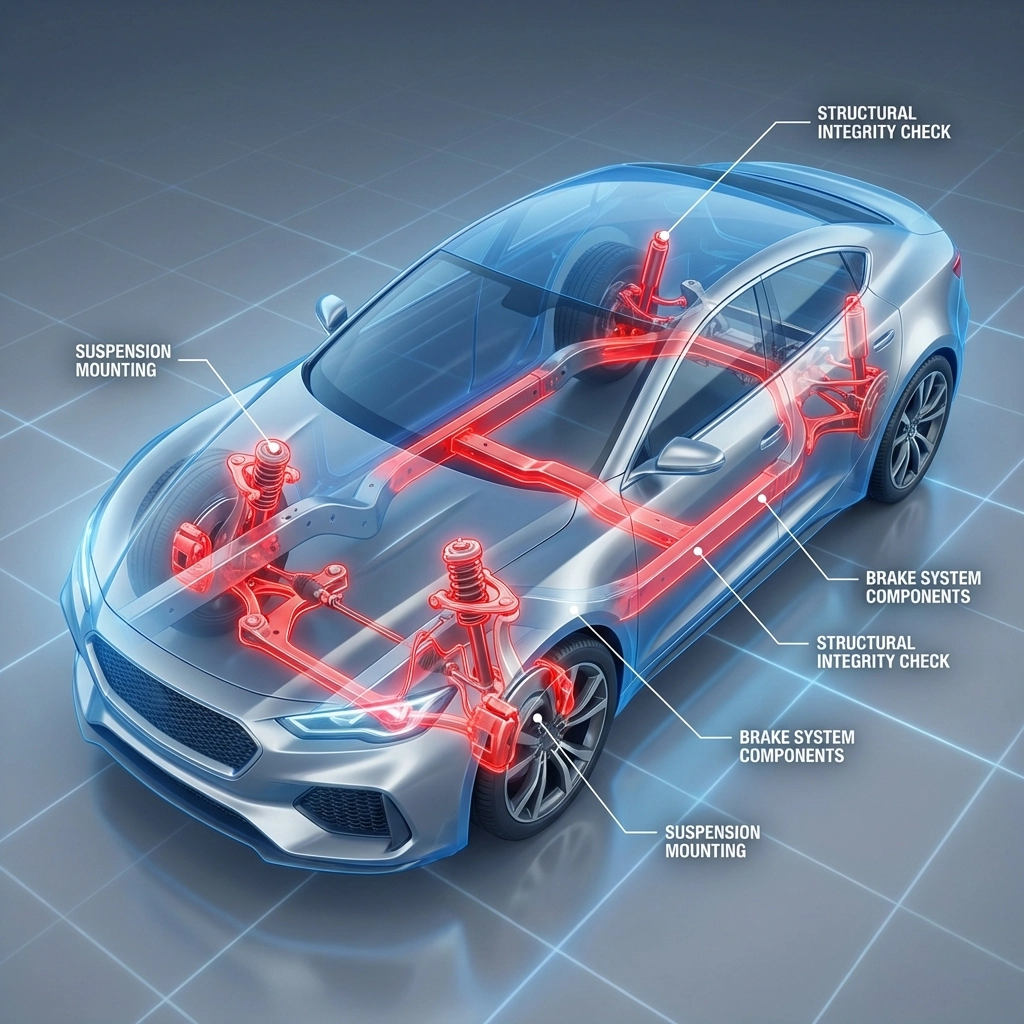

MOT testers focus specifically on prescribed structural areas that are critical for vehicle safety. These include:

Suspension mounting points where corrosion could compromise vehicle stability

Brake system mounting areas essential for stopping performance

Structural chassis members that maintain vehicle integrity

Safety-critical bodywork including seatbelt mounting points

Professional rustproofing treatments prioritise these areas, ensuring comprehensive protection of MOT-critical zones while maintaining inspection accessibility.

Extent and Impact Evaluation

The severity of any visible corrosion determines whether it constitutes a failure. MOT criteria specify that failures occur when rust:

Affects prescribed structural areas beyond acceptable limits

Creates holes or significant structural loss that compromises safety

Generates sharp edges or safety hazards that could cause injury

Compromises the attachment of safety-critical components

Premium rustproofing treatments prevent corrosion from reaching these critical thresholds, providing long-term protection that supports consistent MOT success.

Strategic Timing: Scheduling Rustproofing Around MOT Tests

Professional advice consistently recommends scheduling rustproofing treatments after successful MOT completion rather than before. This strategic approach offers multiple advantages:

Clean Assessment Benefits

Arranging rustproofing immediately following MOT success ensures your vehicle receives a completely clean assessment without any protective coating complications. This approach eliminates potential confusion during inspection and provides baseline documentation of your vehicle's condition.

Optimal Protection Timing

Post-MOT rustproofing provides twelve months of premium protection leading up to the next inspection. This timing maximises the protective benefits while ensuring the treatment remains in optimal condition for subsequent MOT assessments.

Documentation Advantages

Professional treatment documentation obtained after MOT completion provides valuable evidence of proactive maintenance for future inspections. This demonstrates responsible ownership and helps establish the condition timeline for your vehicle.

Professional Rustproofing: The MOT-Compliant Solution

Highest-quality professional rustproofing services understand MOT requirements intimately and design treatments to provide maximum protection while maintaining full compliance. Expert application ensures optimal coverage without creating inspection complications.

Comprehensive Treatment Protocols

Professional services employ systematic treatment protocols that address every vulnerable area while preserving access to MOT inspection points. This meticulous approach eliminates the risk of obstruction-related advisories.

Thorough undercarriage preparation ensures optimal treatment adhesion and longevity, preventing the deterioration issues that could expose underlying corrosion during future MOT inspections.

Quality Assurance and Guarantees

Professional rustproofing guarantees provide additional reassurance for MOT compliance. These warranties demonstrate confidence in treatment quality and longevity, supporting consistent MOT success throughout the protection period.

Photo documentation of treatment application provides valuable evidence of comprehensive coverage and professional standards, supporting any potential MOT queries about protective coating quality.

Maintaining MOT Compliance Through Professional Care

Regular maintenance of protective treatments ensures continued MOT compliance and optimal vehicle protection. Professional services often include complimentary inspection services to monitor treatment condition and address any concerns before they impact MOT outcomes.

Preventive Monitoring

Annual treatment inspections identify any areas requiring attention before MOT testing. This proactive approach prevents surprise failures and maintains the protective integrity that supports consistent MOT success.

Treatment Refreshing

Professional top-up services address any minor treatment deterioration, ensuring protective coatings remain in optimal condition for MOT compliance. This ongoing care maximises the return on your rustproofing investment.

Expert Recommendations for MOT Success

Vehicle owners concerned about MOT compliance should prioritise professional rustproofing services that understand testing requirements and apply treatments accordingly. This expert approach eliminates compliance concerns while providing lifetime rust protection.

Comprehensive pre-treatment inspections identify and address any existing corrosion before protective application, ensuring MOT compliance from the outset. Professional services provide complete transparency about vehicle condition and treatment requirements.

The investment in premium rustproofing treatment provides exceptional value through consistent MOT success, extended vehicle life, and enhanced resale value. This comprehensive protection approach represents the optimal strategy for responsible vehicle ownership.

For vehicle owners seeking MOT-compliant rustproofing solutions that provide lifetime protection and peace of mind, professional consultation ensures the optimal treatment approach for your specific requirements and circumstances.

Comments