Can MOT testers fail you for covering rust?

- Lloyd Saunders

- Nov 4, 2025

- 5 min read

This is one of the most common concerns among vehicle owners who've invested in professional rustproofing or underseal treatments. The straightforward answer is no – MOT testers cannot fail your vehicle simply for having rust covered with protective coatings. However, the reality is more nuanced than this simple answer suggests.

Understanding the relationship between rust covering and MOT testing is crucial for every vehicle owner, whether you're considering rustproofing or have already had treatment applied. Let's examine the official guidelines, assessment procedures, and what vehicle owners need to know about MOT testing when protective coatings are present.

The Official Position on Covered Rust

According to MOT testing guidelines, examiners assess vehicles based on what they can observe and verify during inspection. When areas are completely covered with underseal, wax, or other protective treatments that prevent proper examination, testers typically issue advisories rather than outright failures.

The key principle is simple: MOT testers can only assess what they can see and properly examine. If a protective coating completely obscures an area, preventing adequate inspection, the examiner cannot make a definitive assessment about the underlying condition.

However, complications arise when protective coverings deteriorate, peel away, or allow rust to become visible during the inspection process. Once corrosion is exposed and observable, testers must assess it according to standard failure criteria, regardless of any protective coating that may have been previously applied.

What Actually Triggers MOT Rust Failures

MOT failures related to corrosion are based on location, extent, and structural impact – not the presence or absence of covering materials. Understanding these failure criteria helps clarify why covering rust isn't automatically problematic:

Prescribed Structural Areas

The most serious failures occur when significant corrosion affects load-bearing members, supporting structures, or structural paneling. These areas are critical to vehicle safety and integrity, making any substantial rust in these locations a mandatory failure regardless of covering.

Suspension and Brake Mounting Points

Corrosion within 30cm of suspension or braking component mounting points on inner wheel arches triggers automatic failure. This reflects the critical importance of these areas for vehicle safety and control.

Structural Integrity Issues

When rust creates holes, splits, or causes loss of structural rigidity in safety-critical components, failure is inevitable. The concern here is actual structural compromise, not cosmetic appearance.

Sharp Edges and Safety Hazards

Outer wheel arch corrosion that creates sharp or jagged edges capable of causing injury represents another failure category, focusing on immediate safety risks to users and pedestrians.

MOT Assessment Methods and Limitations

MOT testers follow strict guidelines when assessing potentially corroded areas, using prescribed tools and techniques that limit how aggressively they can examine covered surfaces.

The Corrosion Assessment Tool

Examiners use a specialized corrosion assessment tool for evaluating questionable areas, but regulations strictly restrict its application. The tool cannot be used for heavy scraping or aggressive probing of affected areas – only to ascertain whether established failure criteria are met.

Physical Assessment Techniques

Testers may apply finger or thumb pressure to check whether an area maintains structural rigidity or crumbles due to corrosion. This gentle approach ensures thorough assessment without causing unnecessary damage to protective coatings or vehicle surfaces.

Visual Inspection Priorities

The emphasis remains on visual inspection wherever possible, with physical testing reserved for areas where visual assessment proves insufficient to determine compliance with safety standards.

When Covering Becomes Problematic

While covering rust doesn't automatically cause MOT failures, certain scenarios can create complications during testing:

Deteriorated Protective Coatings

When underseal or other protective treatments begin peeling, cracking, or deteriorating, they may expose underlying rust that becomes subject to standard assessment criteria. This situation often results in advisories or failures based on the newly visible corrosion.

Inadequate Coverage

Partial covering that leaves rust partially visible creates assessment challenges. Testers must evaluate what they can observe, potentially leading to failures if visible corrosion meets failure criteria.

Interference with Safety Inspections

If protective coatings prevent proper inspection of safety-critical areas, examiners may issue advisories noting their inability to complete thorough assessment. While not failures, these advisories highlight potential concerns for future testing.

Best Practices for Vehicle Owners

Understanding MOT guidelines helps vehicle owners make informed decisions about rust protection and maintenance strategies:

Professional Application Standards

High-quality professional rustproofing, when properly applied, typically doesn't interfere with MOT testing. Reputable treatments like Dinitrol systems are designed to provide long-lasting protection while maintaining compatibility with inspection requirements.

Timing Considerations

Scheduling rustproofing treatments after MOT testing can help avoid any potential complications during inspection. This approach ensures clean assessment of vehicle condition before applying protective treatments.

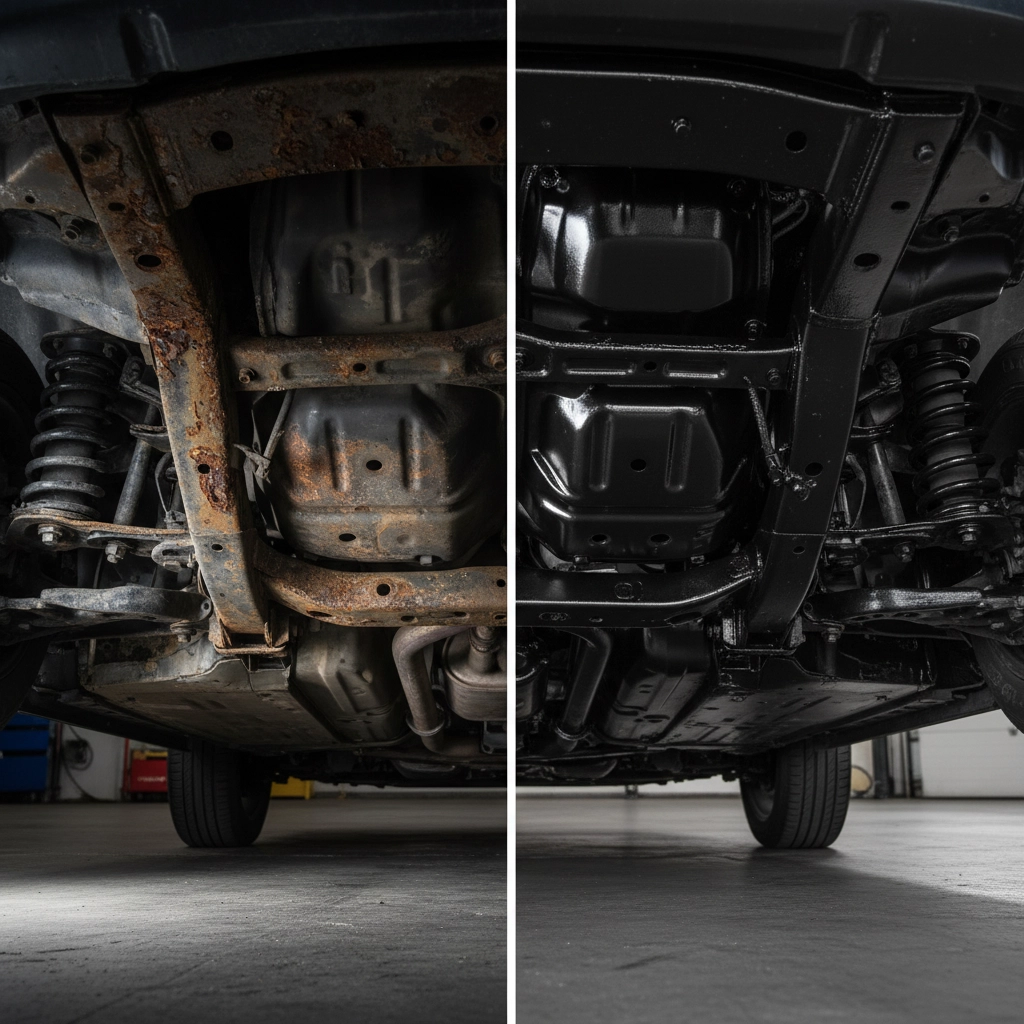

Documentation and Transparency

Maintaining records of rustproofing treatments, including before-and-after photographs, can help demonstrate proactive maintenance approaches to MOT testers and support discussions about vehicle condition.

Regular Monitoring

Even with protective coatings applied, regular inspection of treated areas helps identify any deterioration or emerging issues before they become MOT concerns.

The Rustec Approach to MOT Compatibility

At Rustec, we understand the importance of providing rust protection that enhances rather than complicates vehicle maintenance and testing. Our comprehensive approach ensures treatments meet the highest standards while maintaining full compatibility with MOT requirements.

Pre-Treatment Assessment

Our detailed inspection process identifies and addresses existing corrosion issues before applying protective treatments. This thorough approach ensures underlying problems don't create future MOT complications.

Premium Product Selection

We exclusively use proven systems like Dinitrol ML cavity wax and Lanoguard treatments that provide long-lasting protection without interfering with legitimate safety inspections.

Professional Application Standards

Our meticulous application process ensures complete coverage where needed while avoiding interference with critical inspection points and safety components.

Transparent Documentation

Every Rustec treatment includes comprehensive photo documentation showing before-and-after conditions, providing clear evidence of work completed and vehicle condition at time of treatment.

Making Informed Decisions

The relationship between rust covering and MOT testing needn't be a source of concern for vehicle owners who approach rustproofing thoughtfully. Professional treatments applied by experienced specialists provide excellent protection while maintaining full compatibility with testing requirements.

The key lies in choosing reputable products, professional application, and understanding that quality rust protection enhances rather than compromises vehicle safety and compliance.

For vehicle owners considering rustproofing or concerned about existing treatments, consulting with experienced professionals ensures optimal outcomes that protect both your investment and your peace of mind.

Expert Guidance When You Need It

Understanding MOT guidelines and rust assessment procedures can feel complex, but you don't need to navigate these decisions alone. At Rustec, our expertise in both rust protection and MOT requirements ensures you receive advice that serves your vehicle's long-term interests.

Whether you're planning preventive treatment for a new vehicle or addressing emerging corrosion concerns, our team provides the transparency and professional guidance needed to make confident decisions about your vehicle's protection and compliance.

Contact Rustec today for expert consultation on rust protection strategies that enhance your vehicle's longevity while maintaining full MOT compatibility. Our comprehensive approach ensures your investment in rust protection delivers lasting value and peace of mind.

Comments