Can I pressure wash over Dinitrol?

- Lloyd Saunders

- Nov 12, 2025

- 4 min read

Vehicle maintenance after professional rustproofing treatment raises important questions about care and preservation. One of the most frequently asked questions our Rustec specialists encounter concerns pressure washing over Dinitrol treatments. Understanding the correct approach ensures your investment in premium rust protection remains effective for years to come.

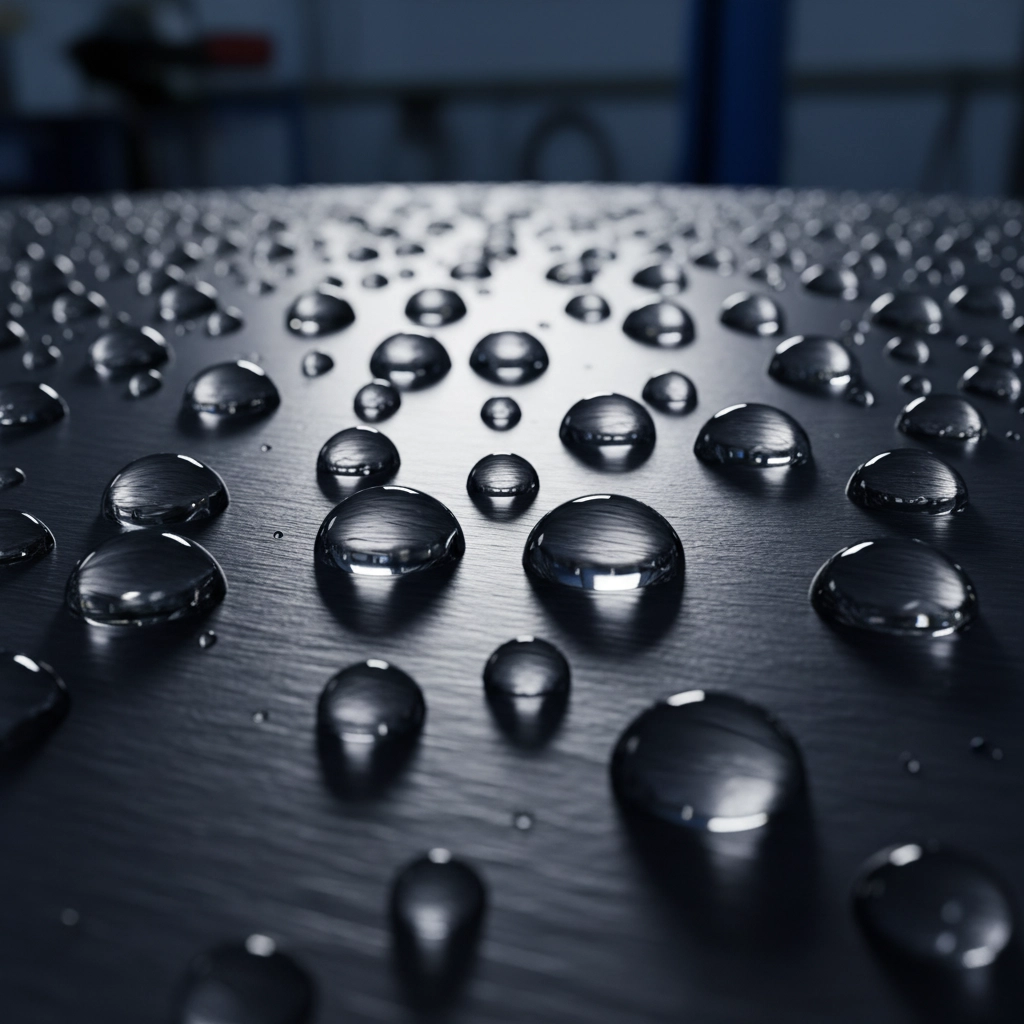

Understanding Dinitrol's Water Resistance Properties

Dinitrol represents the pinnacle of modern rust prevention technology, engineered specifically to withstand the harsh conditions encountered by vehicles in the UK. This premium rustproofing solution demonstrates exceptional water resistance properties, making it fundamentally different from basic underseals or temporary protective coatings.

The molecular structure of Dinitrol creates a resilient barrier that maintains its protective qualities when exposed to moisture. This water resistance is precisely why professional rustproofing specialists choose Dinitrol for comprehensive vehicle protection. However, understanding the limitations of this resistance proves crucial for maintaining optimal protection levels.

The Safe Approach to Pressure Washing

Yes, you can pressure wash over Dinitrol, but the technique and pressure levels require careful consideration. Regular pressure washing at standard household pressure levels will not compromise or blast away properly applied Dinitrol treatments. A standard garden hose with a decent pressure fitting provides sufficient cleaning power for routine maintenance without risking damage to your protective coating.

The key lies in understanding what constitutes "standard" versus "excessive" pressure. Professional-grade pressure washers operating at moderate settings remain safe for Dinitrol-treated surfaces. However, commercial or industrial-strength equipment operating at maximum pressure levels can potentially compromise the protective barrier.

Critical Limitations: Steam Cleaning and High Pressure

Steam cleaning must be avoided entirely after Dinitrol application. The combination of heat and moisture inherent in steam cleaning can soften Dinitrol, reducing its effectiveness and potentially causing the protective layer to become compromised. This represents the most significant limitation when considering cleaning methods for Dinitrol-treated vehicles.

High-pressure settings that exceed manufacturer recommendations pose similar risks. While Dinitrol demonstrates impressive resilience, subjecting it to "uber pressure" levels can result in partial removal or damage to the protective coating. This defeats the purpose of professional rustproofing treatment and potentially exposes vulnerable metal surfaces to corrosion.

Professional Best Practices for Post-Treatment Cleaning

Our Rustec specialists recommend adopting a methodical approach when cleaning Dinitrol-treated vehicles. Begin with the lowest effective pressure setting and gradually increase only if necessary. Focus on removing dirt and debris rather than attempting to strip away every trace of road grime through aggressive pressure application.

Recommended cleaning sequence:

Start with low-pressure rinse to remove loose debris

Apply appropriate cleaning solution if required

Use moderate pressure for stubborn contamination

Finish with thorough low-pressure rinse

Allow complete air drying before inspection

The use of specialized undercarriage cleaning lances, when operated carefully, can effectively maintain cleanliness while preserving Dinitrol protection. These tools distribute pressure more evenly and reduce the risk of concentrated high-pressure impact on treated surfaces.

Understanding Pressure Limitations and Equipment Selection

Standard household pressure washers typically operate between 1,400-2,000 PSI, falling well within safe parameters for Dinitrol-treated surfaces. Professional detailing equipment may exceed these levels, requiring operator awareness and appropriate pressure adjustment.

Equipment considerations:

Household pressure washers: Generally safe when used appropriately

Professional equipment: Requires pressure moderation

Steam cleaners: Strictly prohibited

Soft brush attachments: Excellent for gentle cleaning

Wide-angle nozzles: Distribute pressure more safely than concentrated jets

The angle of application also influences safety. Direct perpendicular pressure application creates maximum impact, while angled approach reduces concentrated force on the protective coating.

Alternative Cleaning Methods

When doubt exists regarding appropriate pressure levels, alternative cleaning methods provide effective maintenance without risk to Dinitrol protection. Soft-bristled brushes combined with low-pressure water flow offer excellent cleaning results while maintaining complete safety margins.

Manual washing using appropriate automotive detergents removes contamination effectively without mechanical stress on protective coatings. This approach proves particularly beneficial for vehicles operating in challenging environments where frequent cleaning becomes necessary.

Alternative techniques:

Soft brush and low-pressure water combination

Manual washing with automotive-specific detergents

Steam-free degreasing agents for stubborn contamination

Regular garden hose with adjustable nozzle settings

Signs of Compromised Protection

Understanding indicators of potential Dinitrol damage enables early detection and corrective action. Visual inspection following cleaning reveals whether protective coating remains intact and effective.

Warning signs to monitor:

Visible removal or thinning of protective coating

Exposed metal surfaces in previously treated areas

Changes in coating texture or consistency

Unusual wear patterns following cleaning

Early detection enables prompt professional assessment and potential reapplication before corrosion damage occurs.

The Importance of Professional Application Quality

The resilience of Dinitrol against pressure washing depends significantly on professional application quality. Our Rustec technicians ensure complete surface preparation, optimal product temperature, and appropriate application thickness for maximum durability.

Professional application advantages:

Comprehensive surface preparation and cleaning

Optimal product viscosity through temperature control

Consistent application thickness across all surfaces

Methodical coverage of vulnerable areas

Quality assurance through systematic inspection

Properly applied Dinitrol demonstrates superior resistance to mechanical cleaning compared to DIY applications or substandard professional work.

Maintaining Long-Term Protection Effectiveness

Regular maintenance cleaning using appropriate techniques preserves both appearance and protective qualities of Dinitrol treatments. Establishing consistent cleaning routines prevents accumulation of corrosive substances while maintaining coating integrity.

Maintenance schedule recommendations:

Monthly undercarriage inspection and cleaning

Immediate cleaning following exposure to road salt

Seasonal comprehensive cleaning and assessment

Professional inspection annually or every 12,000 miles

This systematic approach maximizes the lifespan of your rustproofing investment while maintaining optimal protection levels.

When Professional Assessment Becomes Necessary

Certain situations warrant professional evaluation of Dinitrol condition and effectiveness. Our Rustec specialists provide comprehensive inspections to assess coating integrity and recommend appropriate maintenance or reapplication.

Professional consultation indicators:

Uncertainty regarding cleaning method safety

Visible changes in coating appearance or texture

Exposure to extreme cleaning conditions

Regular heavy-duty use requiring frequent cleaning

Annual maintenance inspection requirements

Professional assessment provides peace of mind and ensures continued optimal protection for your vehicle investment.

Conclusion: Balancing Cleaning and Protection

Pressure washing over Dinitrol remains entirely feasible when approached with appropriate technique and equipment selection. The key lies in understanding pressure limitations, avoiding steam cleaning, and adopting graduated cleaning approaches that prioritize protection preservation.

Our Rustec team stands ready to provide expert guidance on maintaining your Dinitrol treatment effectively. Whether you require specific cleaning technique advice or comprehensive protection assessment, our specialists ensure your rustproofing investment delivers maximum long-term value.

Ready to ensure optimal care for your Dinitrol treatment? Contact our Rustec specialists for professional maintenance advice and inspection services. Our comprehensive approach to rustproofing care ensures your vehicle receives the expert attention it deserves, maintaining premium protection standards throughout its operational life.

Trust Rustec for professional rustproofing solutions and ongoing maintenance support. Your vehicle's long-term protection depends on expert application and informed maintenance practices.

Comments