Why new cars still need rustproofing in the UK

- Lloyd Saunders

- Oct 25, 2025

- 5 min read

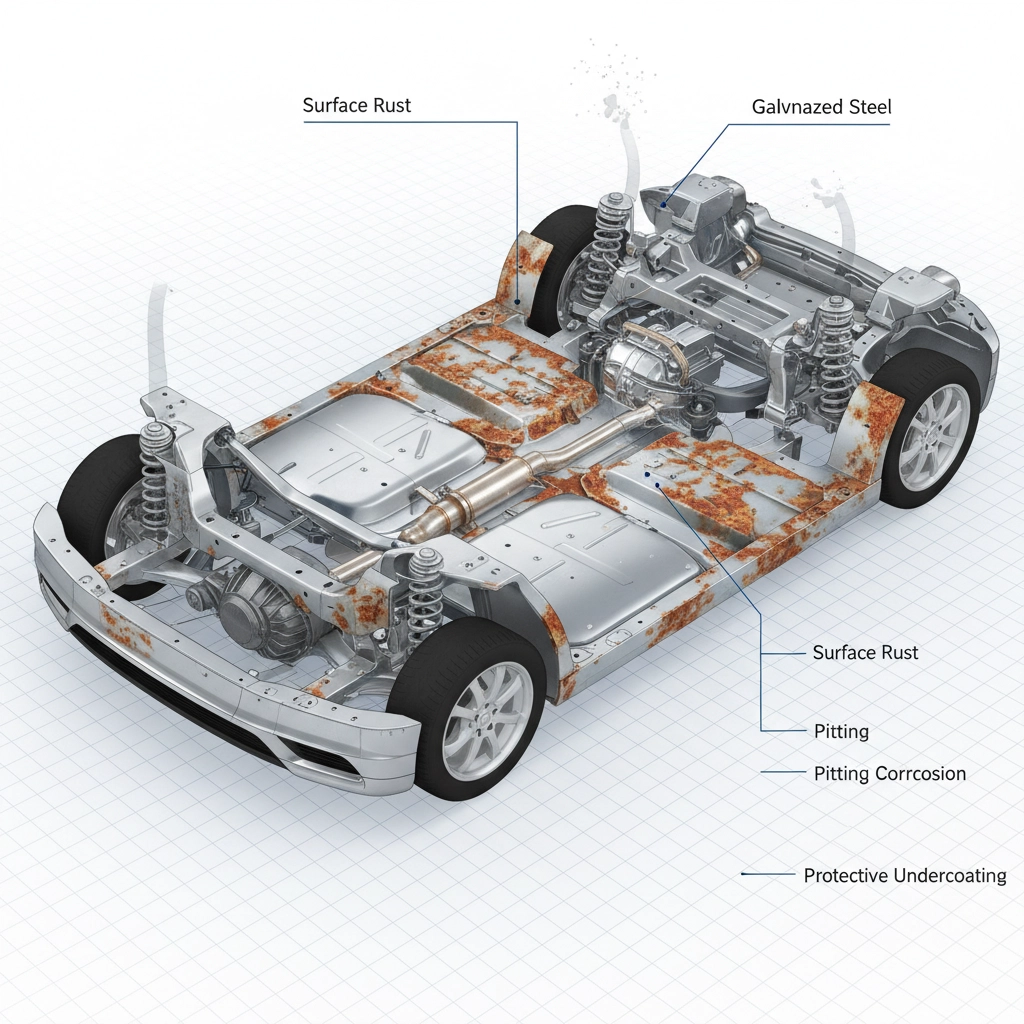

Many new car owners assume their vehicle comes with comprehensive rust protection straight from the factory. While modern manufacturing has significantly improved corrosion resistance compared to vehicles from previous decades, the harsh realities of UK driving conditions mean that additional rustproofing remains essential for optimal long-term protection.

The misconception that new cars don't require rustproofing stems from advances in galvanisation technology and improved paint systems. However, these factory protections are designed for average global conditions, not the specific challenges faced by vehicles operating in the UK's demanding environment.

The UK's Uniquely Corrosive Environment

The United Kingdom presents particularly challenging conditions for vehicle preservation. During winter months, local authorities apply approximately 2 million tonnes of road salt across the UK's road network to maintain safe driving conditions. This road salt creates a highly corrosive environment that accelerates rust formation on all metal components.

Salt doesn't simply wash away after winter passes. It accumulates in hidden areas, wheel arches, and chassis components where moisture becomes trapped. Even during dry periods, residual salt crystals continue their corrosive work, drawing moisture from the atmosphere and maintaining constant metal degradation.

Coastal areas face additional challenges from salt-laden sea air, which carries corrosive particles inland for significant distances. This natural salt exposure combines with road salt to create an exceptionally aggressive environment for vehicle metalwork.

The UK's frequent rainfall compounds these problems by providing the moisture necessary for rust formation. Water penetrates behind plastic trim pieces, bumpers, and protective covers, reaching metal surfaces where it remains trapped for extended periods.

Factory Protection Has Limitations

Modern vehicle manufacturers employ galvanisation processes that provide zinc coating to steel components. This zinc layer acts as a sacrificial barrier, corroding before the underlying steel begins to rust. However, galvanisation has inherent limitations that make additional protection necessary.

Factory rust protection systems are designed to meet minimum warranty requirements, typically covering visible rust perforation for 6-12 years. This protection focuses primarily on body panels and structural components that are easily accessible during manufacturing. Hidden areas, complex joints, and enclosed spaces often receive minimal or no factory treatment.

Manufacturing processes can also compromise factory protection. Welding operations burn away protective coatings at joint areas, creating vulnerable points where rust can begin. Assembly procedures may scratch or damage protective layers, leaving exposed metal surfaces susceptible to corrosion.

Cost considerations during manufacturing mean that protective treatments are applied only where absolutely necessary to meet warranty obligations. Comprehensive protection of every surface would significantly increase production costs, making vehicles uncompetitive in the marketplace.

Imported Vehicles Require Special Attention

A significant proportion of new cars sold in the UK are manufactured overseas, particularly in Japan, South Korea, and other Asian markets. These vehicles are designed and protected for their home market conditions, which often differ dramatically from UK requirements.

Japanese Domestic Market (JDM) vehicles exemplify this challenge. Japan's mild winters rarely require road salt application, and the climate is generally less corrosive than UK conditions. Consequently, Japanese manufacturers apply minimal rustproofing to vehicles intended for domestic use, as extensive protection would represent unnecessary cost and weight.

When these vehicles are imported to the UK, they arrive with protection systems inadequate for local conditions. The first UK winter exposes these vehicles to salt concentrations they were never designed to handle, leading to accelerated corrosion in vulnerable areas.

European-manufactured vehicles fare better, as they are typically designed with northern European winter conditions in mind. However, even these vehicles benefit from additional protection, particularly in hidden areas and complex structural joints.

Vulnerable Areas Require Targeted Protection

Despite factory improvements, certain areas of every vehicle remain particularly susceptible to rust formation. These vulnerable zones require specific attention from professional rustproofing treatments.

Chassis rails and structural components bear the brunt of road salt exposure while providing limited access for factory protection application. These areas accumulate salt, dirt, and moisture throughout winter months, creating ideal conditions for corrosion initiation.

Wheel arches face constant bombardment from road debris, salt spray, and standing water. The complex shapes and hidden surfaces in these areas make thorough factory protection difficult to achieve and maintain.

Sill sections and door frames contain enclosed spaces where moisture can accumulate without adequate drainage. Factory protection often cannot reach these internal cavities, leaving them vulnerable to hidden rust formation.

Suspension mounting points and subframe connections experience stress and movement that can crack protective coatings over time. These critical safety components require comprehensive protection to maintain structural integrity throughout the vehicle's service life.

Professional Rustproofing Delivers Comprehensive Coverage

Professional rustproofing treatments address the limitations of factory protection by providing comprehensive coverage of all vulnerable areas. Advanced products like Dinitrol® cavity wax penetrate into enclosed spaces that factory treatments cannot reach, creating barriers against moisture and salt intrusion.

Modern rustproofing materials are specifically formulated for UK conditions, offering superior resistance to salt corrosion compared to generic factory treatments. These premium products maintain their protective properties for extended periods, providing long-term defense against the UK's aggressive environment.

Professional application ensures thorough coverage of all vulnerable areas through systematic inspection and treatment protocols. Experienced technicians identify potential problem areas and apply appropriate treatments to prevent rust formation before it begins.

Treatment documentation provides vehicle owners with detailed records of protection applied, supporting warranty claims and enhancing resale values. This professional approach delivers peace of mind that cannot be achieved through factory protection alone.

Cost-Effectiveness of Prevention

Investing in professional rustproofing for new vehicles delivers exceptional value compared to repair costs incurred when rust eventually develops. Minor rust repairs can cost hundreds of pounds, while major structural work may require thousands of pounds investment or render vehicles economically unviable.

Comprehensive rustproofing treatment typically costs a fraction of potential repair expenses while providing protection throughout the vehicle's service life. This preventive approach maintains vehicle reliability, safety, and resale value far more effectively than reactive repairs after damage occurs.

MOT test failures due to rust-related issues can be completely avoided through proactive protection. The inconvenience, expense, and safety concerns associated with structural rust make prevention the most sensible approach for any vehicle owner.

Insurance valuations and resale prices reflect the condition of vehicle undercarriages and hidden areas. Professional rustproofing documentation demonstrates proactive maintenance that supports higher valuations when selling or trading vehicles.

Protecting Your Investment

New vehicle purchases represent significant financial investments that deserve comprehensive protection from day one. Waiting until rust appears means accepting unnecessary depreciation and potential safety compromises that professional rustproofing can prevent entirely.

Rustec's comprehensive rustproofing treatments provide the protection your new vehicle needs to withstand UK conditions throughout its service life. Our meticulous application processes ensure every vulnerable area receives appropriate treatment using premium Dinitrol® products specifically formulated for British conditions.

Don't let the UK's harsh environment compromise your vehicle's integrity and value. Contact our specialists today to discuss comprehensive rustproofing solutions tailored to your specific vehicle and requirements. Protect your investment with professional treatment that delivers lifelong peace of mind.

Comments