Should I use a compressor or hand sprayer for rustproofing?

- Lloyd Saunders

- 3 days ago

- 5 min read

When it comes to protecting your vehicle from the UK's harsh conditions, choosing the right application method for rustproofing can make all the difference between a professional-quality finish and a substandard treatment. Whether you're considering a DIY approach or simply want to understand what your service provider should be using, the choice between a compressor-driven system and a hand sprayer is crucial for achieving optimal coverage and long-lasting protection.

Understanding Your Rustproofing Application Options

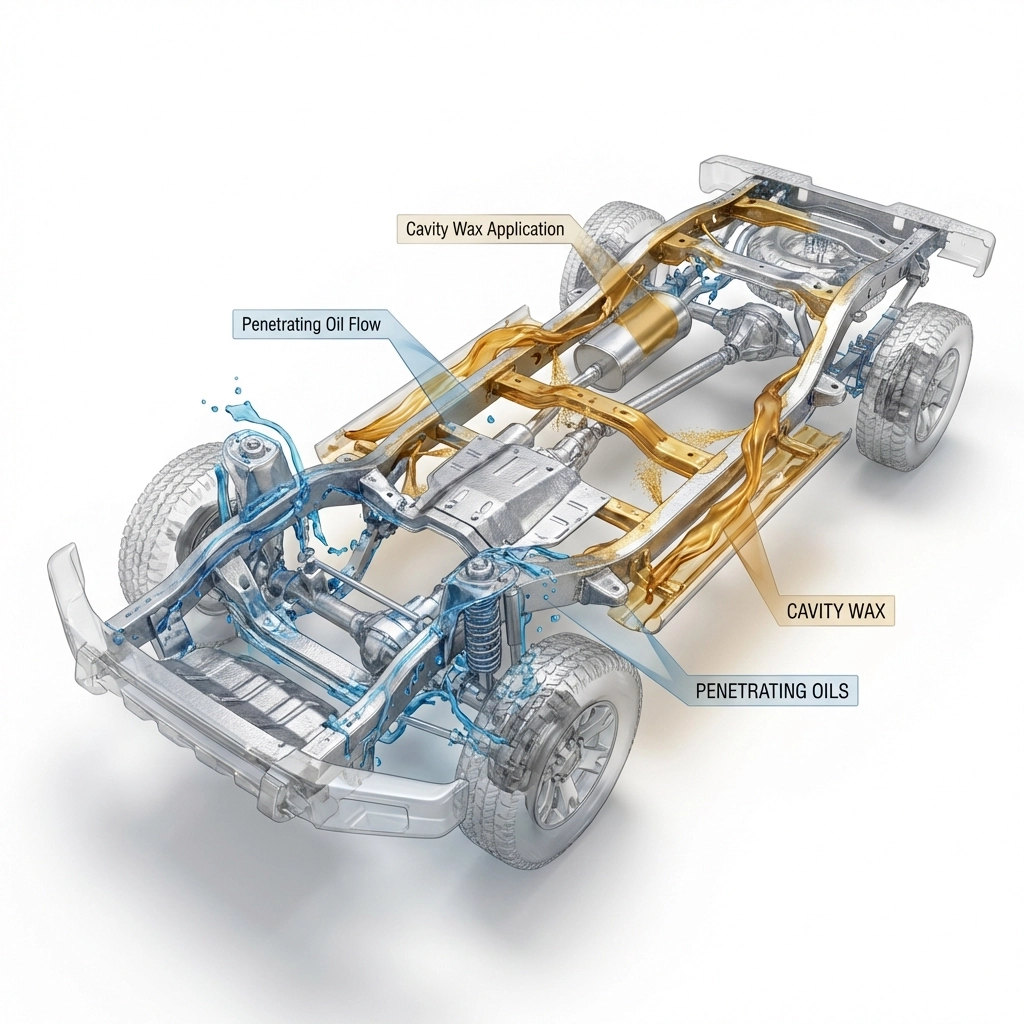

The application method you choose will directly impact the quality, coverage, and longevity of your rustproofing treatment. Modern rustproofing products like Dinitrol, Lanoguard, and traditional Waxoyl formulations require precise application to achieve maximum effectiveness, particularly when treating cavity areas, wheel wells, and the undercarriage where rust typically begins its destructive process.

Professional rustproofing specialists consistently achieve superior results through carefully selected equipment that ensures comprehensive coverage while minimising waste. Understanding these methods helps you make an informed decision about your vehicle's protection strategy.

Compressor-Based Spray Systems: The Professional Standard

Compressor-driven spray systems represent the gold standard for rustproofing applications, offering unmatched versatility and control when applying protective coatings. These systems utilise compressed air to atomise rustproofing materials, creating a fine, consistent spray pattern that penetrates into even the most challenging areas of your vehicle's undercarriage.

Superior Coverage and Penetration

Compressor systems excel at handling various rustproofing material viscosities, from lightweight penetrating oils to thicker cavity waxes. The pressurised air ensures consistent atomisation, allowing products like Dinitrol ML cavity wax to reach deep into box sections, door frames, and structural cavities where rust formation typically begins unnoticed.

The controlled pressure delivery enables technicians to adjust spray patterns for different vehicle areas - from wide coverage for large undercarriage sections to precise targeting for specific vulnerable points around suspension components and chassis joints.

Equipment Specifications and Requirements

For effective rustproofing applications, a compressor with a minimum 3-gallon tank capacity provides adequate air storage and pressure consistency. Professional-grade systems typically feature:

Pressure regulation capabilities (20-100 PSI range)

Moisture filtration systems to prevent contamination

Variable spray pattern controls for different application areas

High-volume, low-pressure (HVLP) compatibility for reduced overspray

Professional Advantages

The versatility of compressor systems allows for seamless transition between different rustproofing products during a comprehensive treatment. Technicians can efficiently apply penetrating oils, followed by protective waxes, and finish with structural cavity treatments - all using the same base equipment with appropriate attachments.

Temperature control becomes manageable with compressor systems, as heated product delivery remains consistent even during extended application periods. This proves particularly valuable when treating larger commercial vehicles or conducting multiple treatments in challenging weather conditions.

Hand Sprayer Systems: Accessible DIY Solutions

Hand-operated spray systems, including garden sprayers and manual pump units, offer an accessible entry point for DIY enthusiasts seeking to protect their vehicles without significant equipment investment. These systems work through manual pressurisation, creating sufficient pressure to deliver rustproofing materials through specially designed nozzles.

Practical Applications and Limitations

Hand sprayers work effectively for localised treatments and maintenance applications, particularly when applying products like Lanoguard to specific areas showing early rust signs. The manual control allows careful application around sensitive components such as electrical connections, sensors, and rubber seals.

However, coverage consistency presents the primary challenge with hand sprayers. Pressure variations during manual pumping can result in uneven application, with some areas receiving excessive product while others remain inadequately protected. This inconsistency becomes particularly problematic when treating large surface areas or attempting comprehensive undercarriage coverage.

Cost-Effectiveness and Accessibility

The lower initial investment makes hand sprayers attractive for budget-conscious vehicle owners planning occasional maintenance treatments. Quality hand sprayers capable of handling rustproofing materials typically cost significantly less than compressor systems, making them suitable for single-vehicle applications or periodic touch-up treatments.

Portability represents another advantage, as hand sprayers require no external power source and can be easily transported to different locations or stored in compact spaces.

Critical Factors in Equipment Selection

Vehicle Type and Treatment Scope

Commercial vehicles, 4x4s, and daily drivers subject to harsh conditions benefit significantly from compressor-based systems due to their superior coverage capabilities. The comprehensive protection these vehicles require demands consistent application across extensive surface areas, making manual systems impractical for thorough treatment.

Classic car enthusiasts often prefer compressor systems for their precision control capabilities, allowing careful application around delicate components while ensuring complete protection of vulnerable structural areas.

Product Compatibility Requirements

Different rustproofing formulations require specific application pressures and spray patterns for optimal effectiveness:

Penetrating oils require fine atomisation for maximum surface penetration

Cavity waxes need controlled pressure to ensure proper flow into structural voids

Structural treatments demand consistent delivery for uniform coating thickness

Environmental Considerations

UK climate conditions significantly impact application success. Compressor systems maintain consistent performance across temperature ranges, while hand sprayers may struggle with material viscosity changes during cold weather applications.

Indoor application facilities benefit from compressor systems' reduced overspray characteristics when combined with HVLP technology, creating cleaner working environments and reducing material waste.

Professional Recommendations and Best Practices

Equipment Selection Criteria

Professional rustproofing specialists consistently choose compressor-based systems for their reliability, consistency, and superior results. The investment in quality equipment pays dividends through:

Reduced treatment time and labour costs

Consistent coverage quality across all vehicle types

Versatility for different rustproofing products and applications

Professional finish quality that enhances customer satisfaction

Maintenance and Longevity Considerations

Properly maintained compressor systems provide decades of reliable service, while hand sprayers typically require more frequent replacement due to seal deterioration and component wear. The total cost of ownership often favours compressor systems for regular use applications.

Making the Right Choice for Your Needs

DIY Enthusiasts

For occasional maintenance treatments or single-vehicle applications, quality hand sprayers can provide adequate results when used with appropriate technique and realistic expectations. Focus on localised problem areas and accept that comprehensive coverage may require professional intervention.

Professional Standards

Vehicle owners seeking maximum protection and longevity should prioritise services utilising professional compressor-based systems. The superior coverage, material penetration, and application consistency justify the investment through extended protection periods and enhanced rust prevention effectiveness.

Long-term Value Perspective

Consider rustproofing as a long-term investment in vehicle preservation. Professional application using appropriate equipment typically provides superior value through extended protection periods, reduced maintenance requirements, and preserved resale value.

The choice between compressor and hand sprayer systems ultimately depends on your specific requirements, budget constraints, and quality expectations. However, for comprehensive rustproofing that provides reliable, long-lasting protection against the UK's challenging environmental conditions, compressor-based application represents the most effective solution.

Professional rustproofing services utilising quality equipment and premium materials like Dinitrol deliver the comprehensive protection your vehicle deserves, ensuring years of reliable service and maintained value despite harsh road conditions and environmental challenges.

Comments