Is factory rust protection enough?

- Lloyd Saunders

- Nov 4, 2025

- 5 min read

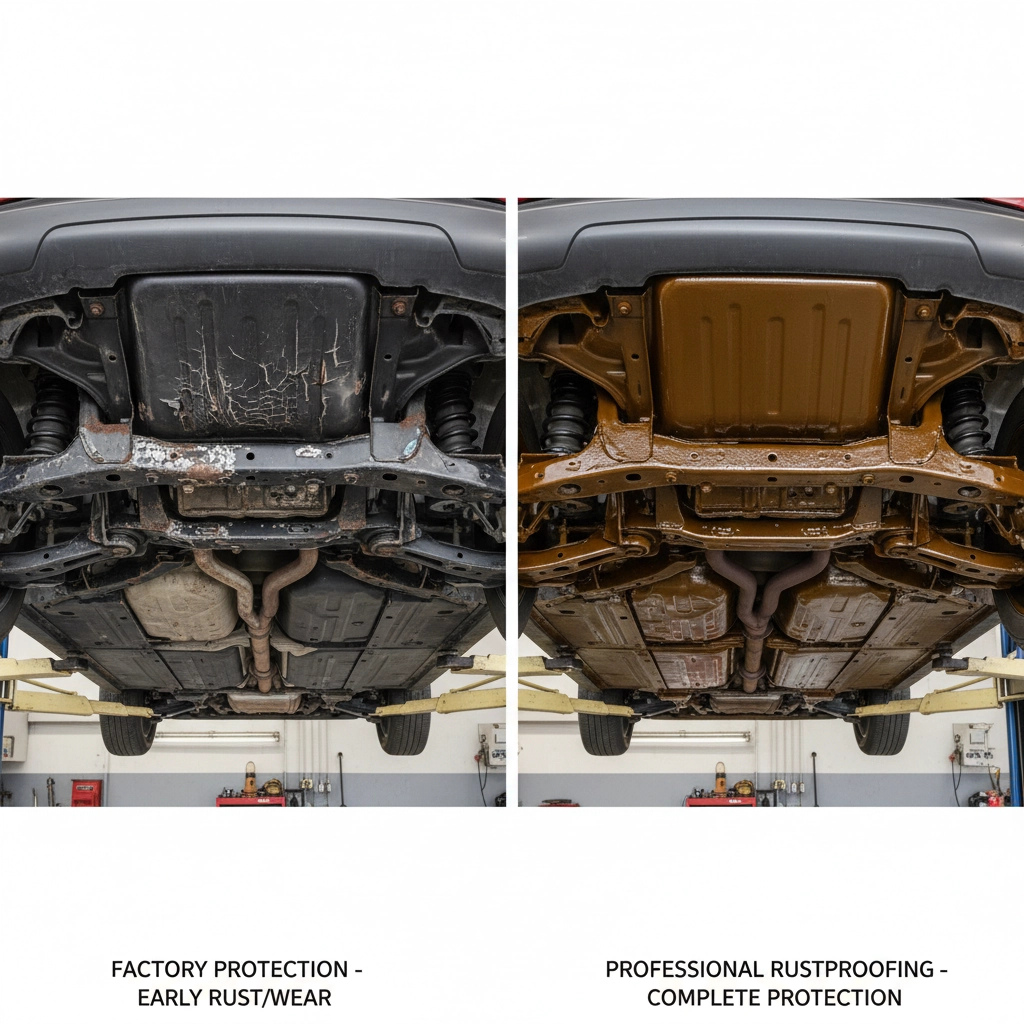

When you drive your brand-new vehicle off the forecourt, it's natural to assume you're fully protected against rust and corrosion. After all, manufacturers invest heavily in modern rust protection systems, and most new cars come with extensive corrosion warranties. However, the reality is more complex than many vehicle owners realise.

Factory rust protection provides a foundation, but it's designed as basic protection rather than comprehensive, long-term defence against the UK's challenging environmental conditions.

What Factory Rust Protection Actually Includes

Modern vehicle manufacturers employ several rust prevention techniques as standard. Galvanised steel forms the primary defence, with zinc coating applied to steel panels during production. This galvanisation process creates a barrier that sacrifices itself to protect the underlying metal, but this protection has finite limits.

Manufacturers also apply primer coatings, paint systems, and basic underseal treatments to critical areas. These factory-applied treatments meet minimum standards required for warranty coverage, typically ranging from 6 to 12 years depending on the manufacturer. However, these warranties often come with strict conditions and may not cover damage caused by environmental factors or normal wear.

The critical point many vehicle owners miss is that factory protection is engineered to meet warranty obligations rather than provide lifetime protection. Manufacturers calculate their corrosion warranties based on expected protection duration under normal conditions, not the harsh realities of UK roads and climate.

The Limitations of Factory Rust Protection

Factory rust protection faces several significant limitations that become apparent over time. The protective coatings applied at the factory are designed for efficiency and cost-effectiveness rather than maximum longevity.

Manufacturing processes require compromise. Factory underseal application happens on production lines with time constraints, meaning coverage may be inconsistent in hard-to-reach areas. Complex chassis designs, cavity spaces, and overlap joints often receive minimal protection due to accessibility challenges during mass production.

Furthermore, factory coatings are formulated to cure quickly and allow immediate handling, which can compromise their long-term adhesion and penetration properties. Professional-grade treatments like Dinitrol® and Lanoguard require longer curing times but provide superior protection as a result.

Why UK Conditions Overwhelm Factory Protection

The UK presents particularly challenging conditions for vehicle corrosion protection. Our combination of high humidity, frequent rainfall, and aggressive winter road treatments creates an environment that rapidly degrades factory protection systems.

Road salt remains the most destructive factor affecting UK vehicles. Local authorities apply approximately 2 million tonnes of rock salt to UK roads annually, creating a corrosive environment that persists well beyond winter months. This salt spray reaches every surface of your vehicle's underside, accelerating corrosion wherever protection is compromised.

Coastal areas present additional challenges through salt-laden air, while industrial regions contribute atmospheric pollutants that further accelerate corrosion processes. Even seemingly minor factors like poor drainage design can create moisture traps that compromise factory protection over time.

The UK's moderate temperatures create another challenge often overlooked by vehicle owners. Unlike extreme climates where salt and moisture freeze solid or evaporate completely, UK conditions maintain corrosive elements in their most active state for extended periods throughout the year.

When Factory Protection Fails

Factory rust protection begins failing from the moment your vehicle enters service. Physical damage represents the most immediate threat to protective coatings. Stone chips, car park scrapes, and minor impacts create breach points where corrosion can establish itself.

Off-road driving, construction site visits, or even poorly maintained car parks can damage underseal and protective films. Once breached, these areas become corrosion initiation points that spread rapidly if left untreated.

Age-related degradation affects all factory protection systems. Protective films become brittle, adhesion fails, and microscopic cracks allow moisture penetration. This process accelerates significantly after the first few years of service, often coinciding with warranty expiration periods.

Hidden areas present particular vulnerabilities. Door frames, sill sections, chassis rails, and cavity spaces receive minimal factory protection due to manufacturing constraints. These areas often show corrosion signs before more visible surfaces, creating structural integrity concerns that may not become apparent until MOT inspections.

The Professional Rustproofing Advantage

Professional rustproofing treatments provide comprehensive protection that addresses factory protection limitations. Life Long Dinitrol® treatments penetrate areas that factory applications cannot reach, providing complete coverage of vulnerable surfaces.

Professional application allows for thorough preparation including steam cleaning, degreasing, and surface preparation that ensures optimal adhesion. This preparation phase, impossible during vehicle manufacturing, significantly improves treatment longevity and effectiveness.

Advanced products like Dinitrol® ML cavity wax actively penetrate hidden areas through capillary action, providing protection in door frames, chassis sections, and body cavities that remain vulnerable with factory protection alone. These treatments continue working over time, migrating into microscopic cracks and providing self-healing properties.

Professional treatments also offer flexibility in product selection. Different areas of your vehicle benefit from specific treatment types - from thin-film cavity waxes for hidden areas to robust underseal coatings for high-impact zones. This targeted approach provides optimal protection for each surface type and exposure level.

Investment Protection and Long-Term Value

Professional rustproofing represents sound financial planning for vehicle owners. The cost of comprehensive rustproofing typically represents less than 2% of a vehicle's purchase price while potentially extending its serviceable life by many years.

Rust damage progresses exponentially once established. Early intervention through professional rustproofing prevents costly structural repairs, panel replacements, and safety-critical component failure. MOT failure rates due to corrosion increase significantly after year seven, making preventive treatment essential for long-term vehicle ownership.

Resale values benefit significantly from documented rust prevention. Vehicles with professional rustproofing treatments and service records command premium prices in the used car market, as buyers increasingly recognise the value of corrosion-free examples.

Quality Assurance and Professional Standards

Rustec's comprehensive rustproofing service exceeds factory protection standards through meticulous preparation and application procedures. Our thorough undercarriage steam cleaning removes all contamination before treatment application, ensuring optimal adhesion and coverage.

Every vehicle receives comprehensive photographic documentation before and after treatment, providing clear evidence of work completed and baseline condition recording. This documentation proves invaluable for warranty claims and resale purposes.

Our Rustec Guarantee provides confidence in treatment quality and longevity. Unlike factory warranties with multiple exclusions, our guarantee reflects confidence in our preparation standards and product quality.

Professional Inspection and Treatment Planning

Each vehicle requires individual assessment to determine optimal treatment approaches. Our comprehensive inspection identifies existing corrosion, assesses factory protection condition, and develops targeted treatment plans for maximum effectiveness.

This professional assessment often reveals protection gaps that vehicle owners haven't recognised. Early detection and treatment prevent minor issues developing into major structural problems requiring expensive repairs.

Treatment timing proves critical for optimal results. New vehicles benefit from immediate treatment before corrosion initiates, while older vehicles require careful preparation to ensure treatment success over existing protection systems.

Take Action Now - Protect Your Investment

Don't wait for rust to appear before taking action. Professional rustproofing provides maximum value when applied to vehicles with intact factory protection, creating layered defence systems that provide comprehensive long-term protection.

Contact Rustec today to arrange your comprehensive vehicle inspection and treatment consultation. Our expert technicians will assess your vehicle's current protection status and recommend appropriate treatments for your specific requirements and driving conditions.

Book your rustproofing appointment now through our website at rustec.co.uk or call our team directly for immediate consultation. Your vehicle's protection cannot wait - every month of delay allows corrosion processes to advance and compromise your investment.

Professional rustproofing represents the single most effective step you can take to protect your vehicle's long-term value and ensure years of reliable, safe motoring ahead.

Comments