How to prepare a car before rustproofing

- Lloyd Saunders

- Nov 19, 2025

- 5 min read

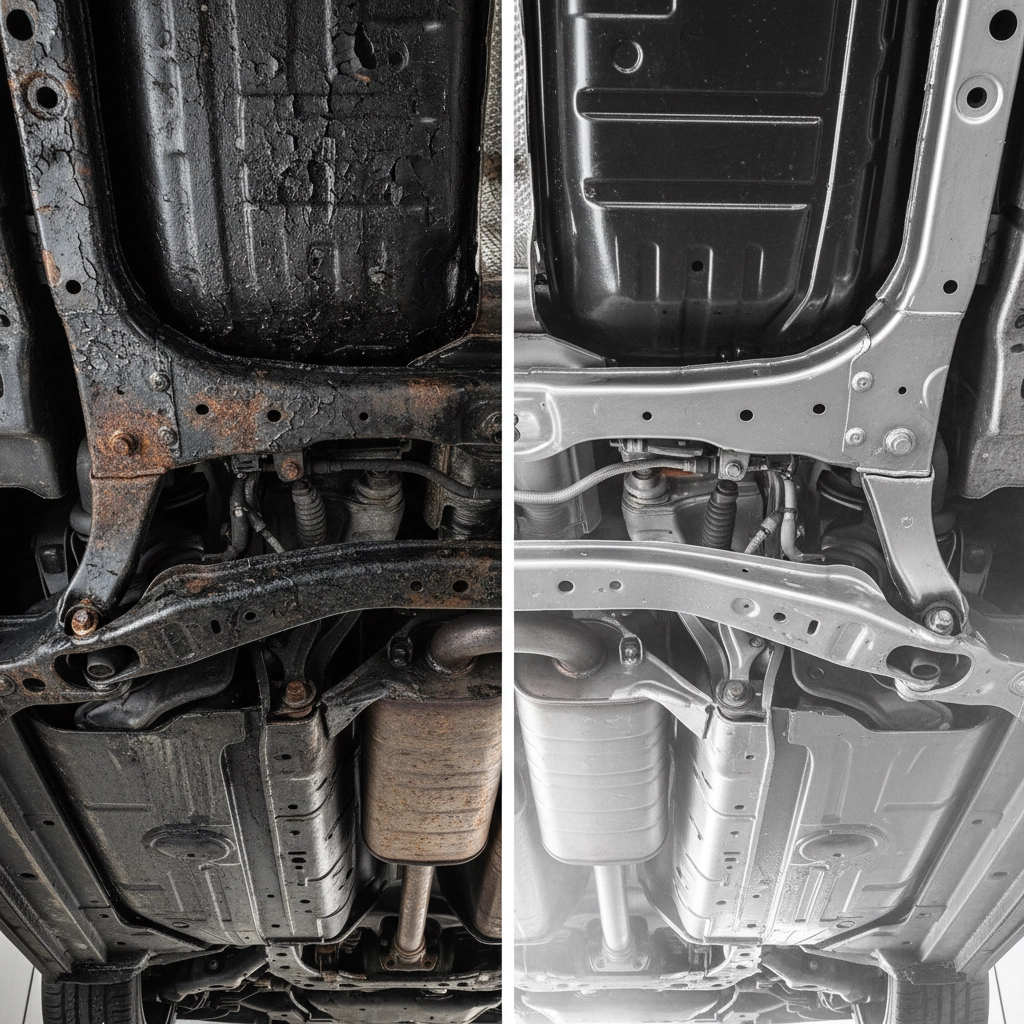

Proper preparation is the foundation of effective rustproofing. Without meticulous surface preparation, even the highest-quality rustproofing products will fail to deliver the long-lasting protection your vehicle deserves. At Rustec, we understand that comprehensive preparation is what separates a professional, lifetime-guaranteed rustproofing treatment from a temporary fix.

Planning Your Preparation Timeline

Before beginning any rustproofing preparation work, set aside adequate time for the project. A methodical approach is essential: plan for at least a long weekend if you're undertaking the work yourself. Professional preparation cannot be rushed, and this stage is typically more time-consuming than applying the rustproofing products themselves.

The preparation phase requires patience and attention to detail. Cutting corners during this crucial stage will compromise the effectiveness and longevity of your rustproofing treatment, regardless of which premium products you subsequently apply.

Essential Safety Equipment and Tools

Investment in proper protective equipment is non-negotiable before commencing preparation work:

Personal Protective Equipment:

High-quality overalls and chemical-resistant gloves

Breathing mask rated for particulates and chemical vapours

Safety goggles or full-face mask protection

Steel-toed boots with slip-resistant soles

Preparation Tools Required:

Wire brushes in various sizes for manual rust removal

Blunt screwdrivers and metal scrapers for coating removal

Variable-speed electric drill with wire wheel attachments

Angle grinder with cup wire wheels for extensive rust treatment

Pressure washer or access to professional steam cleaning equipment

Degreasing agents and panel wipe solutions

Professional-grade tools significantly reduce preparation time and ensure superior surface cleaning compared to basic hand tools alone.

Strategic Component Removal for Complete Access

Thorough rustproofing requires access to all vulnerable areas of your vehicle's undercarriage and body cavities. Determine which components need removal to access critical protection zones:

Wheelarch and Suspension Areas: Remove wheelarch liners and mudflaps to thoroughly access inside wheelarches where rust typically initiates. This requires removing road wheels and supporting the vehicle safely on professional-grade axle stands.

Door and Panel Access: Remove door panels to access the interior cavity spaces where moisture accumulates. Modern vehicles have extensive cavity networks that require proper preparation for effective wax penetration.

Undercarriage Components: Remove plastic undertrays and splash guards to improve access to chassis rails, suspension mounting points, and other structural elements prone to corrosion.

This systematic disassembly ensures no vulnerable area remains inadequately prepared or protected.

Comprehensive Undercarriage Cleaning Process

Begin with a thorough undercarriage cleaning using heated water pressure washing. Professional facilities utilise steam cleaning equipment operating at optimal temperatures to effectively remove accumulated road grime, salt deposits, and previous coating residues.

Initial Cleaning Protocol:

Apply multi-purpose degreasing agents to cut through built-up contamination

Pressure wash all accessible undercarriage surfaces systematically

Clear all drainage holes to prevent moisture entrapment

Allow complete drying for several days before proceeding

Avoid thick or waxy cleaning products during this stage, as these create air pockets on surfaces that become future rust initiation sites. The objective is achieving a completely clean, contamination-free surface ready for rust treatment and product application.

Mechanical Rust Removal and Surface Preparation

All existing rust and deteriorated coatings must be mechanically removed before rustproofing application. This critical stage determines the long-term effectiveness of your rust protection system.

Rust Removal Methodology:

Use angle grinders with cup wire wheels for extensive rust removal

Deploy drill-mounted wire wheels for detailed work in confined spaces

Hand-clean residual rust using progressive wire brush grades

Remove all flaking paint and compromised surface coatings

Old Underseal Removal: Particular attention must be paid to removing brittle, deteriorated underseal. Over time, factory underseal hardens and develops cracks that trap moisture against metal surfaces, accelerating corrosion. Complete removal of compromised underseal is labour-intensive but essential for preventing future rust problems.

Surface Quality Assessment: After mechanical cleaning, surfaces should exhibit clean, sound metal ready for treatment. Any remaining rust spots require treatment with appropriate rust converter chemicals before proceeding with rustproofing application.

Professional Degreasing and Final Surface Preparation

Following mechanical preparation, comprehensive degreasing ensures optimal rustproofing adhesion and penetration:

Degreasing Protocol:

Apply professional-grade degreasers or white spirit to all prepared surfaces

Allow appropriate dwell time for contamination dissolution

Remove all degreasing residues with clean, lint-free cloths

Final surface preparation using panel wipe solutions

This meticulous cleaning process removes invisible contamination that would otherwise prevent proper rustproofing adhesion and compromise treatment effectiveness.

Precision Masking and Area Protection

Professional masking protects surrounding components and ensures clean application boundaries:

Masking Requirements:

Mask exhaust systems, brake components, and electrical connections

Protect CV joints, drive shafts, and suspension bushings

Cover areas where rustproofing application is not required

Use appropriate masking tape grades that won't leave residues

Proper masking demonstrates professional attention to detail and prevents contamination of sensitive vehicle systems during rustproofing application.

Final Pre-Application Inspection

Before rustproofing commencement, conduct a comprehensive inspection of all prepared surfaces:

Quality Control Checklist:

Verify complete rust removal from all accessible areas

Confirm thorough degreasing of all surfaces

Check adequate masking of protected components

Ensure complete surface drying following cleaning processes

Document preparation completion with photographic evidence

This systematic verification ensures your vehicle is optimally prepared for rustproofing treatment application.

Professional Preparation vs DIY Limitations

While dedicated DIY enthusiasts can achieve satisfactory preparation results, professional preparation offers significant advantages:

Professional Advantages:

Access to steam cleaning equipment operating at optimal temperatures

Professional-grade tools for efficient rust removal and surface preparation

Experience identifying hidden rust and vulnerable areas requiring attention

Systematic approach ensuring no critical areas are overlooked

Quality control processes guaranteeing preparation standards

DIY Limitations:

Limited access to professional cleaning equipment

Time constraints affecting thoroughness of preparation work

Potential safety risks without proper equipment and experience

Difficulty accessing all vulnerable areas without professional lifting equipment

The Rustec Professional Preparation Advantage

At Rustec, our comprehensive preparation process forms the foundation of our lifetime guarantee. Our technicians utilise professional steam cleaning equipment, premium preparation tools, and systematic quality control processes to ensure every vehicle receives meticulous surface preparation.

Our preparation service includes complete photographic documentation, allowing you to see exactly what preparation work has been completed on your vehicle. This transparency demonstrates our commitment to professional standards and provides confidence in the quality of work performed.

Professional Preparation Includes:

Complete undercarriage steam cleaning at optimal temperatures

Systematic rust removal using professional equipment

Thorough degreasing with premium cleaning agents

Precision masking of sensitive components

Quality control inspection with photographic documentation

Preparation completion certificate for your records

Don't compromise the effectiveness of your rustproofing investment with inadequate preparation. Contact Rustec today to discuss our professional preparation service and ensure your vehicle receives the meticulous preparation it deserves for lifetime rust protection.

Ready to ensure your vehicle receives professional preparation? Contact Rustec for a comprehensive consultation and quote for our expert preparation and rustproofing services. Your vehicle's long-term protection depends on preparation quality: trust the professionals who guarantee their work for life.

Comments