How do I maintain rustproofing?

- Lloyd Saunders

- Dec 16, 2025

- 5 min read

Maintaining your vehicle's rustproofing investment is essential for ensuring long-term protection against corrosion. A comprehensive maintenance routine will extend the effectiveness of your treatment, preserve your vehicle's structural integrity, and maintain its resale value. Understanding the proper maintenance procedures will help you maximise the performance of your rustproofing system throughout your vehicle's lifetime.

Regular Cleaning and Washing Protocol

Frequent Undercarriage Cleaning

Establishing a rigorous cleaning schedule forms the foundation of effective rustproofing maintenance. Wash your vehicle frequently, paying particular attention to the undercarriage and wheel wells where contaminants accumulate most readily. Road salt, grime, and chemical residues can compromise protective coatings if left to build up over extended periods.

Use a high-pressure hose to thoroughly clear away dirt, salt buildup, and debris from the underbody. This is particularly crucial during winter months when road salt exposure reaches its peak. The salt used for de-icing UK roads is highly corrosive and will accelerate the breakdown of protective treatments if not regularly removed.

Proper Washing Technique

When washing your vehicle, ensure you reach all edges, crevices, and hidden areas where moisture and contaminants tend to collect. These areas are often overlooked during routine cleaning but represent the most vulnerable points for rust initiation. Steam cleaning provides the most effective method for removing stubborn deposits that standard washing cannot eliminate.

Drying and Ventilation

After washing, allow your vehicle to dry thoroughly, especially in enclosed areas where moisture can become trapped. Proper ventilation prevents the accumulation of humidity that can undermine rustproofing treatments. Keep your vehicle in a dry, well-ventilated environment whenever possible.

Comprehensive Inspection and Early Detection

Monthly Visual Inspections

Conduct systematic monthly inspections of your vehicle to identify potential issues before they develop into serious problems. Look for signs of rust damage including bubbling paint, discoloured spots, or areas where protective coatings appear to have worn away. These early warning signs indicate where your rustproofing system may require attention.

Key Inspection Areas

Focus your inspection efforts on high-risk areas including wheel arches, door frames, sill panels, and chassis rails. These locations experience the greatest exposure to road spray and are most susceptible to coating breakdown. Pay particular attention to areas where the protective film may have been damaged by stone chips or impact damage.

Documentation and Monitoring

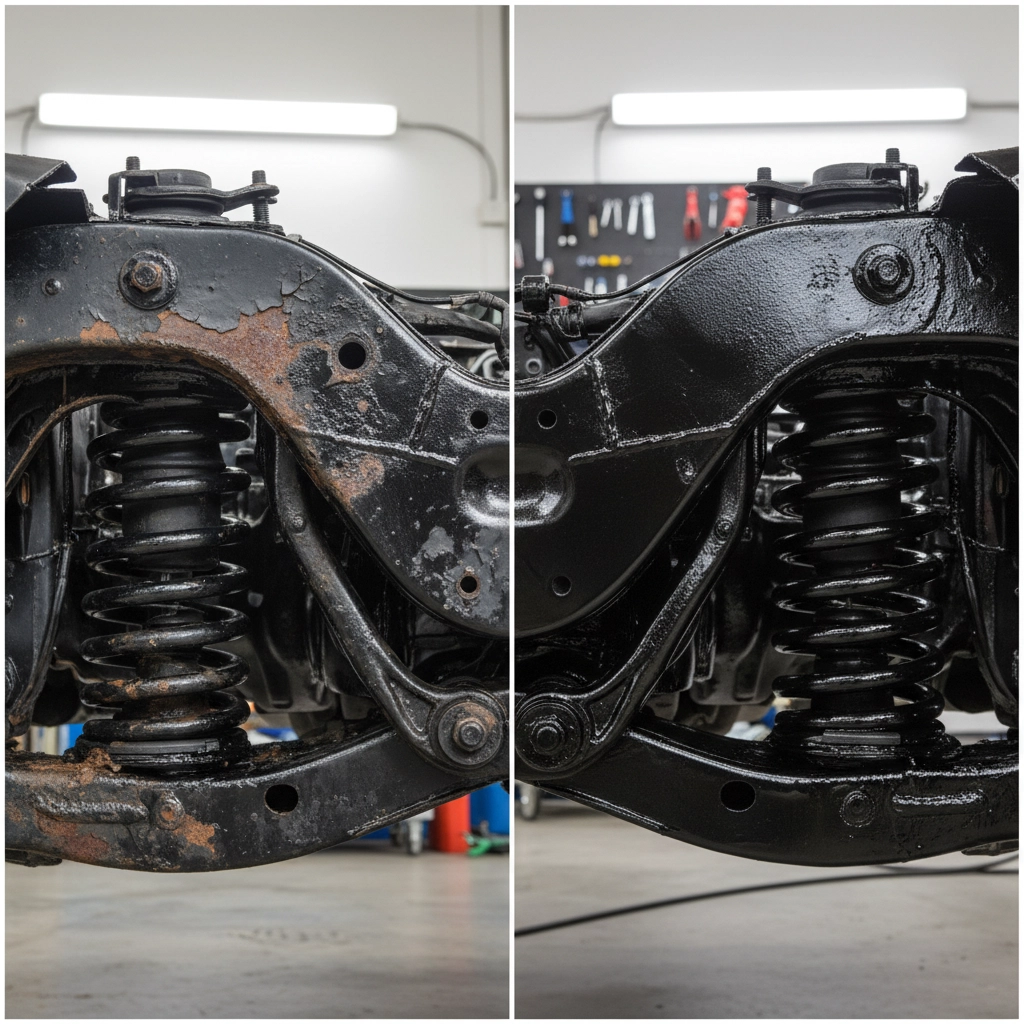

Maintain a photographic record of your vehicle's condition to track any changes over time. This documentation proves invaluable for identifying gradual deterioration that might otherwise go unnoticed. Professional rustproofing services often provide detailed photo documentation as part of their comprehensive inspection process.

Professional Assessment

Consider having your rustproofing system professionally assessed annually. Expert technicians can identify potential issues that may not be apparent to the untrained eye and provide recommendations for maintaining optimal protection levels.

Understanding Reapplication Schedules

Treatment-Specific Requirements

Different rustproofing treatments require varying reapplication schedules based on their formulation and protective mechanisms. Oil-based systems like Dinitrol do not harden and require periodic reapplication to maintain their penetrating and displacing properties. These treatments need to continuously seep into crevices and prevent moisture from settling in vulnerable areas.

Annual Maintenance Recommendations

Most professional rustproofing treatments benefit from annual inspection and potential reapplication. The harsh UK climate, with its combination of salt exposure, high humidity, and temperature fluctuations, can accelerate the breakdown of protective coatings. Annual maintenance ensures your investment continues providing maximum protection.

Seasonal Considerations

The optimal time for rustproofing maintenance typically falls in late autumn, before the onset of winter conditions. This timing allows fresh protection to be applied before the most challenging period for corrosion protection. However, maintenance can be performed year-round when necessary.

Addressing Damage and Wear Promptly

Immediate Response Protocol

Address any scratches, chips, or damage to the protective layer immediately upon discovery. Prompt attention prevents rust from developing beneath compromised coatings. Small areas of damage can quickly escalate into major corrosion issues if left untreated.

Touch-Up Applications

Keep appropriate touch-up materials available for addressing minor damage between scheduled maintenance sessions. These quick repairs can prevent extensive deterioration and maintain the integrity of your rustproofing system. Proper preparation of damaged areas ensures effective adhesion of repair materials.

Professional Repair Services

For significant damage or extensive wear, professional repair services provide the expertise and materials necessary for effective restoration. Professional technicians can assess the extent of damage and recommend appropriate remedial treatments to restore full protection.

Additional Preventive Measures

Mudguard Installation

Install high-quality mudguards to minimise road spray impact on your vehicle's underbody. Mudguards significantly reduce the amount of salt, grit, and moisture that contacts protected surfaces, extending the life of your rustproofing treatment.

Regular Lubrication

Maintain regular lubrication of hinges, latches, and moving parts to prevent rust formation and ensure smooth operation. These components often receive less rustproofing coverage and benefit from additional protection through proper maintenance.

Garage Storage Benefits

Store your vehicle in a dry, ventilated garage whenever possible. Controlled storage conditions reduce exposure to moisture and temperature fluctuations that can accelerate coating breakdown. Proper storage significantly extends the effectiveness of rustproofing treatments.

Drainage Maintenance

Ensure all drainage points and weep holes remain clear and functional. Blocked drainage can lead to water accumulation in protected areas, potentially overwhelming rustproofing treatments. Regular cleaning of drainage systems prevents moisture buildup.

Professional Maintenance Services

Comprehensive Inspection Services

Professional rustproofing specialists offer comprehensive inspection services that go beyond visual assessment. These services include detailed underbody examination, coating thickness measurement, and assessment of treatment effectiveness. Professional inspections provide peace of mind and expert recommendations for maintaining optimal protection.

Specialised Equipment and Materials

Professional maintenance services utilise specialised equipment and premium materials not readily available to DIY enthusiasts. This professional-grade approach ensures thorough application and superior protection levels that extend treatment longevity.

Warranty Protection

Many professional rustproofing services include maintenance requirements as part of their warranty terms. Following recommended maintenance schedules ensures your warranty remains valid and provides recourse if issues develop.

Expert Knowledge and Experience

Professional technicians bring extensive knowledge and experience to rustproofing maintenance. Their expertise in identifying potential issues and recommending appropriate solutions can prevent costly repairs and extend your vehicle's service life.

Long-Term Protection Strategy

Effective rustproofing maintenance requires a systematic approach combining regular cleaning, thorough inspection, timely reapplication, and prompt attention to any damage. This comprehensive strategy ensures your investment in corrosion protection continues delivering maximum value throughout your vehicle's lifetime.

The UK's challenging environment demands vigilant maintenance to preserve rustproofing effectiveness. By following proper maintenance procedures and working with experienced professionals when necessary, you can ensure your vehicle remains rust-free and maintains its structural integrity for years to come.

For expert rustproofing maintenance services and comprehensive protection solutions, contact our professional team at Rustec. Our specialists provide the knowledge, experience, and premium materials necessary to keep your vehicle's rustproofing system performing at its peak effectiveness.

Comments