Do modern cars rust?

- Lloyd Saunders

- Nov 1, 2025

- 5 min read

If you've just bought a shiny new vehicle, you might assume it's completely protected against rust for years to come. After all, modern cars look so much more sophisticated than their predecessors from the 1970s and 80s, which were notorious for developing rust holes within a few short years.

The straightforward answer is yes, modern cars do still rust – but the process has been significantly slowed compared to older vehicles. While manufacturers have made remarkable improvements in rust protection, no car is completely immune to corrosion, and understanding why is crucial for protecting your investment.

Why Modern Cars Are More Rust-Resistant

Today's vehicles benefit from decades of engineering advances specifically designed to combat corrosion. These improvements work together to create multiple layers of protection that previous generations of cars simply didn't have.

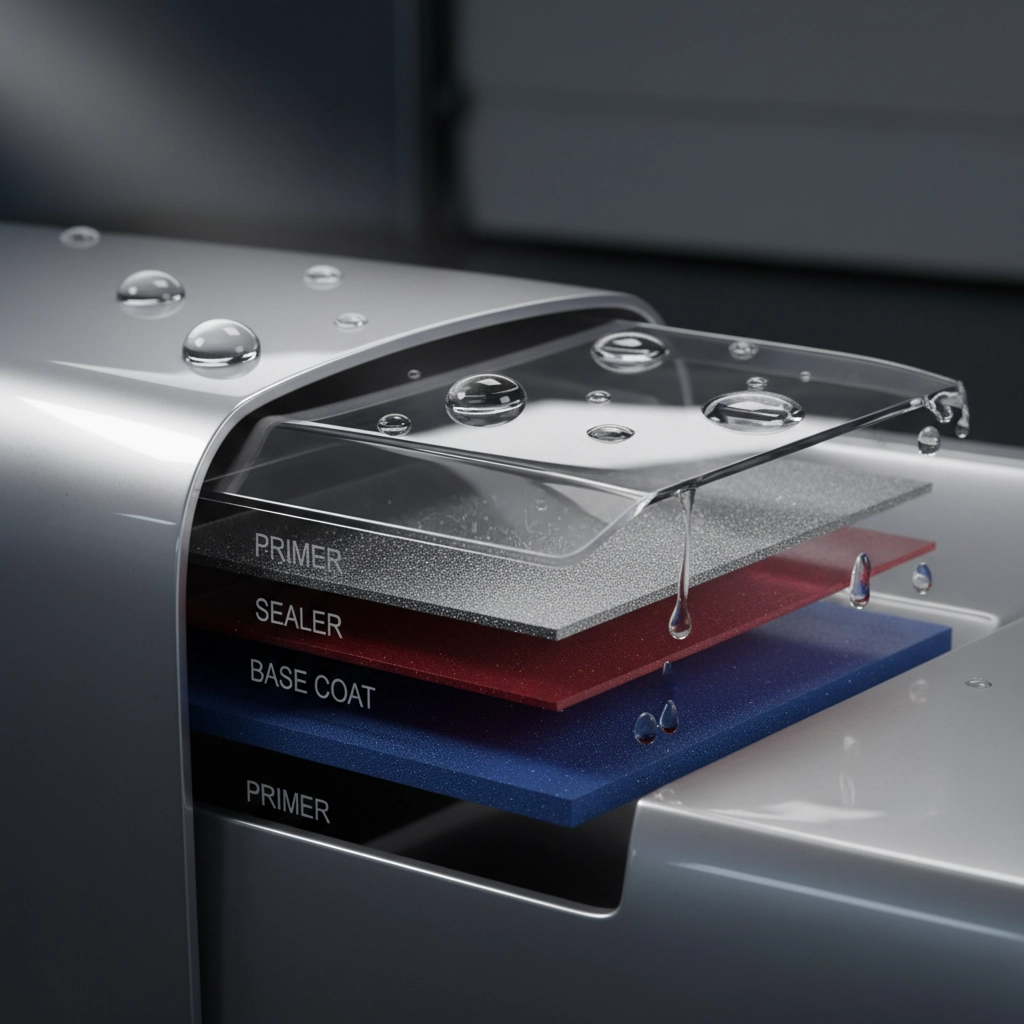

Advanced Paint Technology

Modern automotive paint systems are far superior to those used even two decades ago. Rather than a simple colour coat applied directly to metal, today's vehicles receive a comprehensive multi-layer treatment. This starts with chemical primers that bond directly to the metal surface, followed by sealers that create an additional barrier against moisture penetration.

The final paint layer itself contains sophisticated chemical additives that actively repel water and create an invisible protective shield. This system significantly reduces the direct contact between oxygen, moisture, and the underlying metal – the three elements required for rust formation.

Improved Construction Methods

Vehicle construction has evolved dramatically to eliminate common rust-prone areas. Modern cars are designed with superior water management in mind, featuring better drainage systems and fewer unnecessary seams where moisture can accumulate.

Many manufacturers now use bolts instead of rivets to join body sections, creating tighter seals that prevent water intrusion. Additionally, designers have eliminated traditional rust traps – those pockets and crevices where mud, salt, and moisture would typically gather and remain in contact with metal surfaces.

Hot-Dip Galvanization

One of the most significant advances in rust protection is the widespread adoption of hot-dip galvanization. This process applies a thin zinc coating to steel components, where the zinc acts as a sacrificial anode. In simple terms, if corrosion does occur, the zinc coating corrodes first, protecting the underlying steel structure.

This galvanized protection is particularly effective on chassis components and structural elements that are most vulnerable to road salt and moisture exposure.

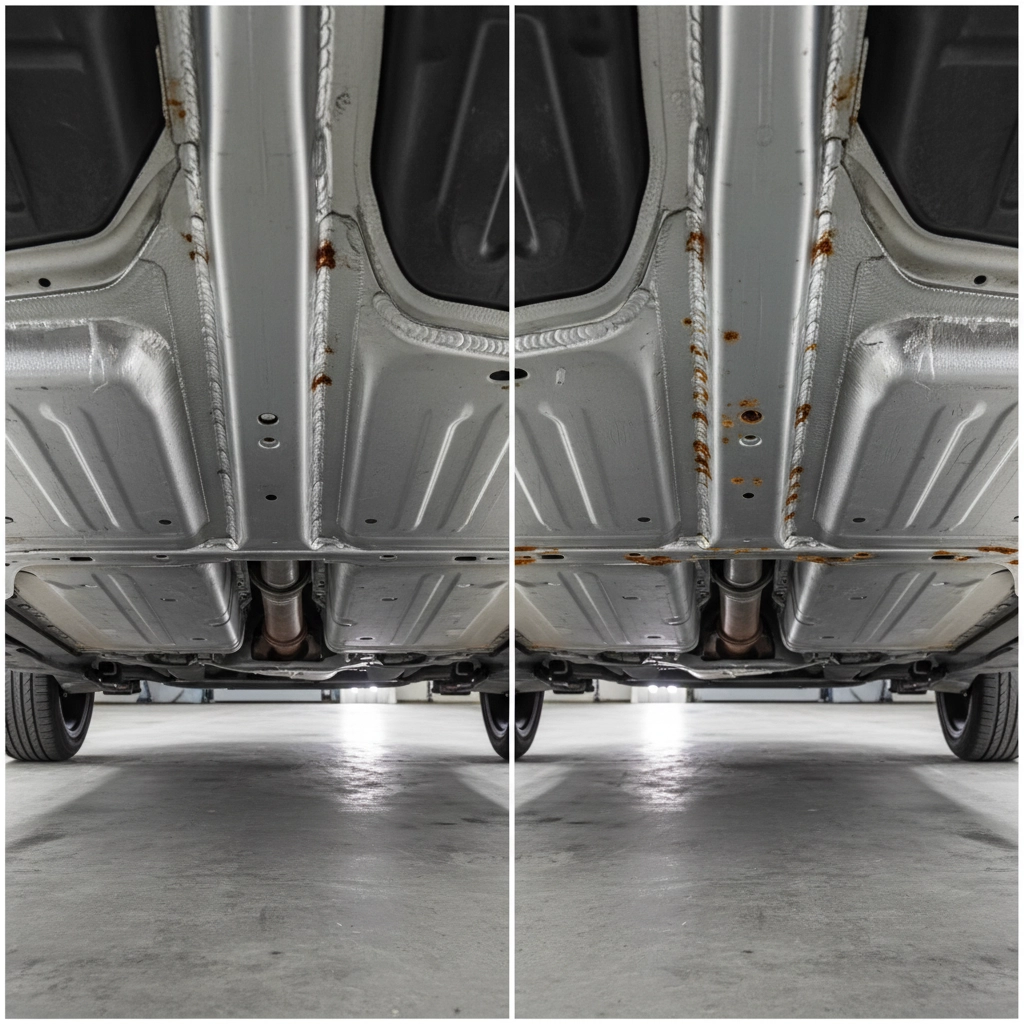

The Reality: Modern Cars Still Corrode

Despite these impressive advances, rust remains a genuine concern for modern vehicle owners. The improvements simply mean corrosion happens more slowly and takes longer to become visually apparent or structurally significant.

Compromised Protection Systems

Even the most advanced rust protection can be compromised. Stone chips, minor accident damage, or simple wear and tear can breach the protective paint layers, exposing bare metal to the elements. Once this happens, rust formation begins at the same rate as it would on any unprotected metal surface.

Galvanized coatings, while highly effective, can also be damaged by road debris or become compromised through manufacturing imperfections. When galvanization fails, the underlying steel becomes vulnerable to accelerated corrosion.

Aluminum Corrosion Issues

Many modern vehicles incorporate aluminum components to reduce weight and improve fuel efficiency. While aluminum doesn't rust in the traditional sense, it can suffer from its own form of corrosion, particularly when in contact with dissimilar metals. This galvanic corrosion can cause just as much structural damage as traditional rust.

Thinner Materials, Faster Deterioration

Ironically, while modern cars take longer to develop rust, they may actually deteriorate more rapidly once corrosion begins. Contemporary vehicles often use thinner gauge metals to reduce weight and manufacturing costs. This means that when rust does penetrate the protective systems, it can eat through the metal more quickly than it would on older, thicker steel components.

UK Conditions: A Perfect Storm for Corrosion

The United Kingdom's climate and road conditions create particularly challenging circumstances for vehicle corrosion protection. Understanding these factors helps explain why even the most advanced factory rust protection may not provide adequate long-term protection.

Road Salt and Chemical De-Icers

British roads are heavily treated with salt and chemical de-icing agents throughout winter months. These substances are specifically designed to break down ice and snow, but they're equally effective at accelerating metal corrosion. Salt creates an electrochemical reaction that dramatically speeds up rust formation, even on protected surfaces.

High Humidity and Frequent Rain

The UK's naturally high humidity levels and frequent rainfall create ideal conditions for rust formation. Unlike drier climates where occasional moisture can evaporate quickly, British vehicles often remain damp for extended periods, giving corrosion processes more time to establish and progress.

Coastal Exposure

Vehicle owners in coastal areas face additional challenges from salt air exposure. Sea salt in the atmosphere can penetrate into the smallest gaps and crevices, creating corrosion even in areas that never directly contact road salt or standing water.

Factory Protection: The Starting Point, Not the Finish Line

Most new vehicles come with some level of factory rust protection, typically including basic undersealing and galvanized components. However, this protection represents a starting point rather than a comprehensive, lifetime solution.

Factory treatments are applied using mass production methods that prioritize efficiency and cost control over thoroughness. Many vulnerable areas receive minimal attention, and the treatments used are often designed to provide adequate protection for warranty periods rather than the vehicle's entire operational life.

Warranty Limitations

Manufacturer corrosion warranties typically cover only perforation – actual rust holes that penetrate completely through the metal. Surface rust, bubbling paint, and early-stage corrosion often fall outside warranty coverage, leaving owners responsible for repair costs.

Additionally, these warranties frequently include exclusions for damage caused by stone chips, minor accidents, or inadequate maintenance, which can void coverage even when significant rust problems develop.

The Economic Reality of Rust Damage

Understanding the financial implications of rust damage helps put the importance of prevention into perspective. Once established, rust problems typically require expensive repairs that far exceed the cost of preventative treatments.

Structural rust can lead to MOT failures, requiring immediate and often extensive welding work. In severe cases, rust damage can render vehicles uneconomical to repair, effectively writing off what might otherwise be a serviceable vehicle.

Beyond repair costs, rust significantly impacts resale value. Even minor visible corrosion can reduce a vehicle's market value by hundreds or thousands of pounds, while documented rust problems can make vehicles virtually unsaleable.

Professional Rustproofing: Comprehensive Protection

While modern cars are more rust-resistant than their predecessors, they still benefit significantly from professional rustproofing treatments that address the limitations of factory protection.

Professional treatments use advanced products like Dinitrol cavity wax systems that can penetrate into areas factory treatments cannot reach. These applications provide comprehensive coverage of vulnerable points including door frames, chassis rails, and suspension mounting areas.

Unlike DIY approaches, professional rustproofing includes thorough preparation work, ensuring optimal adhesion and coverage. This typically involves steam cleaning, degreasing, and careful masking to protect sensitive components while ensuring complete treatment coverage.

Long-Term Value Protection

Professional rustproofing represents an investment in long-term vehicle protection that pays dividends through reduced repair costs, maintained resale value, and extended operational life. Quality treatments can provide protection for many years, far exceeding the cost of the initial application.

Take Action: Protect Your Investment Today

Modern cars may be more rust-resistant than ever before, but they're not rust-proof. The combination of UK road conditions, climate factors, and the limitations of factory protection means that even brand-new vehicles benefit from additional rustproofing treatment.

Don't wait until you spot the first signs of corrosion – by then, the damage process has already begun. Professional rustproofing is most effective when applied to clean, undamaged surfaces, providing maximum protection against future problems.

Ready to protect your vehicle with professional rustproofing? Contact Rustec today for a comprehensive consultation. Our experienced technicians use only the highest-quality products and proven application methods to ensure your vehicle receives lifetime protection against rust and corrosion.

Book your rustproofing treatment now and safeguard your investment against the inevitable challenges of UK road conditions. Your vehicle deserves the premium protection that only professional rustproofing can provide.

Comments