Do galvanised chassis still need rustproofing?

- Lloyd Saunders

- Nov 13, 2025

- 5 min read

The automotive industry has made remarkable strides in rust prevention technology over the past few decades. Galvanised chassis have become the gold standard for modern vehicle construction, offering significantly enhanced protection against corrosion compared to traditional steel components. However, this advancement has left many vehicle owners questioning whether their galvanised chassis still requires additional rustproofing treatment.

The answer isn't as straightforward as you might expect. While galvanisation provides exceptional baseline protection through sophisticated electrochemical processes, the question of whether supplementary rustproofing is necessary depends on several critical factors that every vehicle owner should understand.

Understanding Galvanisation Technology

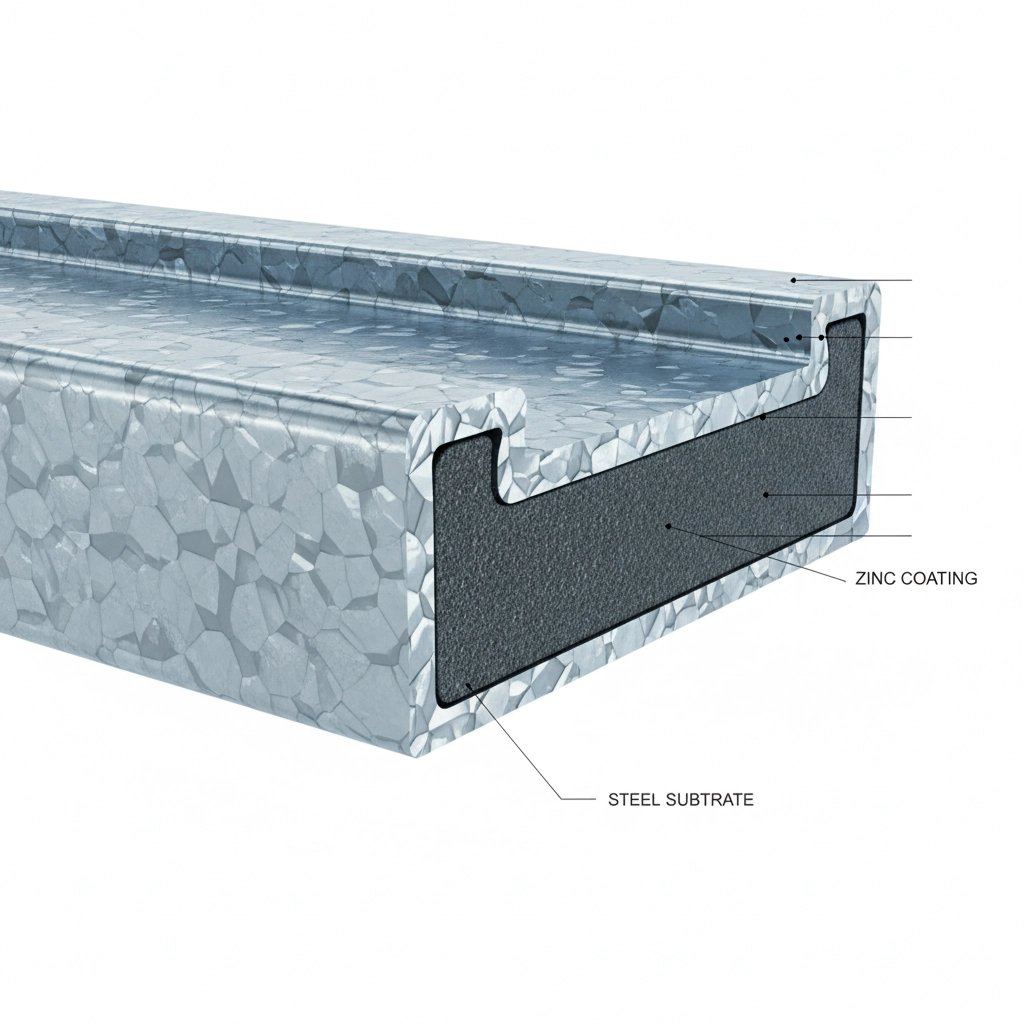

Galvanisation involves coating steel components with a protective layer of zinc through either hot-dip galvanising or electro-galvanising processes. This zinc coating serves as a sacrificial barrier that protects the underlying steel through cathodic protection: a sophisticated electrochemical mechanism that continues working even when the coating surface is compromised.

Unlike paint or other surface treatments, galvanised coatings maintain their protective properties even when scratched, drilled, or cut. The surrounding zinc continues to protect exposed steel areas through electrochemical sacrifice, meaning minor damage doesn't compromise the overall protective system. This fundamental difference makes galvanised chassis significantly more resilient than their non-galvanised predecessors.

Modern automotive manufacturers have embraced galvanisation as standard practice, with premium manufacturers like Land Rover, Mercedes-Benz, and BMW implementing comprehensive galvanising processes across their chassis and body components. This widespread adoption has dramatically reduced automotive rust-related failures compared to vehicles manufactured before the 1990s.

The Inherent Protection of Galvanised Systems

Galvanised chassis provide decades of reliable protection under normal operating conditions without requiring immediate additional treatment. The zinc coating creates an impermeable barrier that prevents moisture and oxygen from reaching the steel substrate, while simultaneously offering cathodic protection through controlled electrochemical sacrifice.

This protection mechanism means that touch-up treatments at damage points are generally unnecessary: a significant advantage over painted steel components that require immediate repair when compromised. The galvanised coating's self-healing properties through cathodic protection ensure continuous defence against corrosion initiation.

Research consistently demonstrates that properly galvanised automotive components can withstand normal environmental exposure for 20-30 years without significant degradation. This longevity explains why many vehicle manufacturers offer extended corrosion warranties on galvanised chassis components, reflecting confidence in the technology's long-term effectiveness.

Limitations and Vulnerabilities

Despite galvanisation's impressive protective capabilities, certain limitations and vulnerabilities warrant consideration when evaluating additional rustproofing requirements. Understanding these factors is crucial for making informed decisions about supplementary protection.

Internal corrosion represents the primary vulnerability of galvanised chassis construction. While external surfaces receive comprehensive galvanised protection, internal cavities and overlapping steel sections often lack adequate zinc coverage. These areas experience moisture accumulation through temperature cycling: warm days followed by cool nights create condensation that can lead to internal oxidation.

Standard galvanising processes struggle to provide uniform coverage within complex chassis geometries, particularly in box sections, door frames, and structural reinforcements. Water ingress through drainage holes, seams, and joints can create ideal conditions for corrosion initiation in areas where galvanised protection is insufficient.

Additionally, the sacrificial nature of zinc coating means prolonged exposure to harsh environmental conditions will eventually deplete the protective layer. Coastal environments with salt spray, regions with aggressive road salt application, and industrial areas with chemical exposure can accelerate zinc consumption, reducing long-term protection effectiveness.

Environmental Factors Affecting Protection Requirements

The decision regarding additional rustproofing for galvanised chassis largely depends on environmental exposure conditions throughout the vehicle's operational life. Different environments present varying levels of corrosive challenge that can influence the longevity of galvanised protection.

Coastal and marine environments present the most aggressive conditions for galvanised components. Salt-laden air and direct seawater exposure accelerate zinc consumption through increased electrochemical activity. Vehicles regularly operated within five miles of coastlines experience significantly higher corrosion rates, making supplementary protection highly beneficial.

Winter road salt application creates similarly challenging conditions for galvanised chassis. While zinc coatings resist salt-induced corrosion better than bare steel, prolonged exposure to road salt solutions can accelerate zinc depletion. Regions with extended winter seasons and heavy salt usage may warrant additional protective measures.

Industrial and urban environments with elevated levels of chemical pollutants, particularly sulfur dioxide and nitrogen oxides, can also impact galvanised coating longevity. These atmospheric contaminants create acidic conditions that increase zinc consumption rates, potentially reducing protection effectiveness over time.

The Case for Supplementary Protection

Professional rust prevention specialists increasingly recommend strategic supplementary protection for galvanised chassis, particularly focusing on internal corrosion prevention and enhanced longevity in challenging environments. This approach recognises galvanisation's excellent baseline protection while addressing its inherent limitations.

Cavity wax treatments using advanced products like Dinitrol ML provide exceptional internal corrosion prevention by penetrating inaccessible areas and creating moisture barriers where galvanised protection may be incomplete. These treatments complement rather than compete with galvanisation, offering comprehensive protection throughout complex chassis geometries.

Modern rust prevention products demonstrate excellent compatibility with galvanised surfaces, enhancing rather than compromising the existing protection. Professional-grade treatments create synergistic protective systems that combine galvanisation's electrochemical benefits with advanced barrier protection against moisture ingress.

For vehicles intended for long-term ownership: particularly commercial vehicles, classic cars, and premium personal vehicles: supplementary protection represents excellent value proposition. The modest investment in professional rustproofing treatments can extend chassis life significantly, maintaining structural integrity and preserving resale value.

Professional Assessment and Treatment

Given the complexity of modern galvanised chassis protection requirements, professional assessment provides invaluable guidance for determining optimal treatment strategies. Experienced rust prevention specialists can evaluate specific vehicle requirements, environmental exposure conditions, and intended usage patterns to recommend appropriate protection measures.

Professional treatments offer significant advantages over DIY approaches, including access to premium-grade materials, specialised application equipment, and comprehensive coverage techniques. Properly trained technicians understand galvanised surface preparation requirements and can ensure optimal adhesion and coverage of supplementary treatments.

Quality assurance through professional application includes thorough cleaning, appropriate surface preparation, and systematic application techniques that ensure complete coverage of vulnerable areas. Professional treatments typically include comprehensive documentation and warranty coverage, providing additional peace of mind.

The investment in professional assessment and treatment represents comprehensive insurance against long-term corrosion challenges. While galvanised chassis provide excellent baseline protection, strategic enhancement through professional rustproofing ensures maximum longevity and structural integrity throughout the vehicle's operational life.

Making the Right Decision for Your Vehicle

The decision regarding additional rustproofing for your galvanised chassis should consider multiple interconnected factors including environmental exposure, intended ownership duration, vehicle usage patterns, and personal risk tolerance. While galvanisation provides remarkable baseline protection, supplementary treatments offer enhanced security and extended longevity.

Long-term vehicle ownership scenarios particularly benefit from supplementary protection, as the modest treatment investment compounds into significant value preservation over extended periods. Commercial vehicle operators, enthusiasts planning extended ownership, and owners in challenging environments should strongly consider professional enhancement treatments.

Warranty considerations also merit attention, as some manufacturers specify approved treatment products and application methods. Professional rust prevention specialists understand these requirements and can recommend treatments that enhance protection without compromising manufacturer warranties.

At Rustec, our experienced specialists provide comprehensive assessment services to determine optimal protection strategies for your specific requirements. We understand the sophisticated interaction between galvanised protection systems and supplementary treatments, ensuring recommendations that maximise long-term chassis integrity and vehicle value.

Contact Rustec today for professional assessment of your galvanised chassis protection requirements. Our expert team will evaluate your vehicle's specific needs and recommend the most effective treatment strategy to ensure decades of reliable, rust-free performance. Protect your investment with proven expertise and premium-quality treatments backed by our comprehensive guarantee.

Comments