Can underbody rust be repaired without welding?

- Lloyd Saunders

- Nov 6, 2025

- 5 min read

When you discover rust creeping across your vehicle's underside, the immediate question isn't whether it can be fixed, it's whether expensive welding work is inevitable. The good news is that many underbody rust issues can indeed be addressed without welding, but understanding the limitations of non-welded repairs versus structural welding is crucial for making informed decisions about your vehicle's longevity.

Understanding the Scope of Non-Welded Rust Repairs

The short answer is yes: underbody rust can often be repaired without welding, depending on the extent and location of the corrosion. Non-welded repairs excel at addressing surface rust, minor through-rust, and cosmetic damage on non-structural components. However, these methods have clear boundaries that every vehicle owner should understand before proceeding.

Non-welded repairs work exceptionally well for areas like splash shields, minor chassis surface rust, bolt-on brackets, and aesthetic underbody panels. They're also highly effective for addressing rust that hasn't compromised the structural integrity of load-bearing components.

Proven Methods for Welding-Free Rust Repair

Body Filler and Mesh Reinforcement

The most established approach involves completely removing rusted material through grinding or cutting, then rebuilding the area with reinforced body filler. This method requires meticulous preparation: every trace of rust must be eliminated to expose clean, sound metal before applying the filler system.

Modern reinforced fillers can handle surprising structural loads when properly applied. The process involves applying a base layer, embedding fibreglass mesh for strength, then building up additional layers to match the original contour. When executed correctly, this repair can last decades under normal driving conditions.

Two-Part Epoxy Panel Adhesives

Professional-grade epoxy panel adhesives represent a significant advancement in non-welded repairs. These systems create molecular bonds that are often stronger than the original metal, making them suitable for attaching patch panels or reinforcing weakened areas without heat application.

The flexibility of quality epoxy systems allows them to accommodate the natural expansion and contraction that occurs in underbody components, preventing the cracking that can plague rigid repair materials. This makes them particularly valuable for areas subject to vibration or thermal cycling.

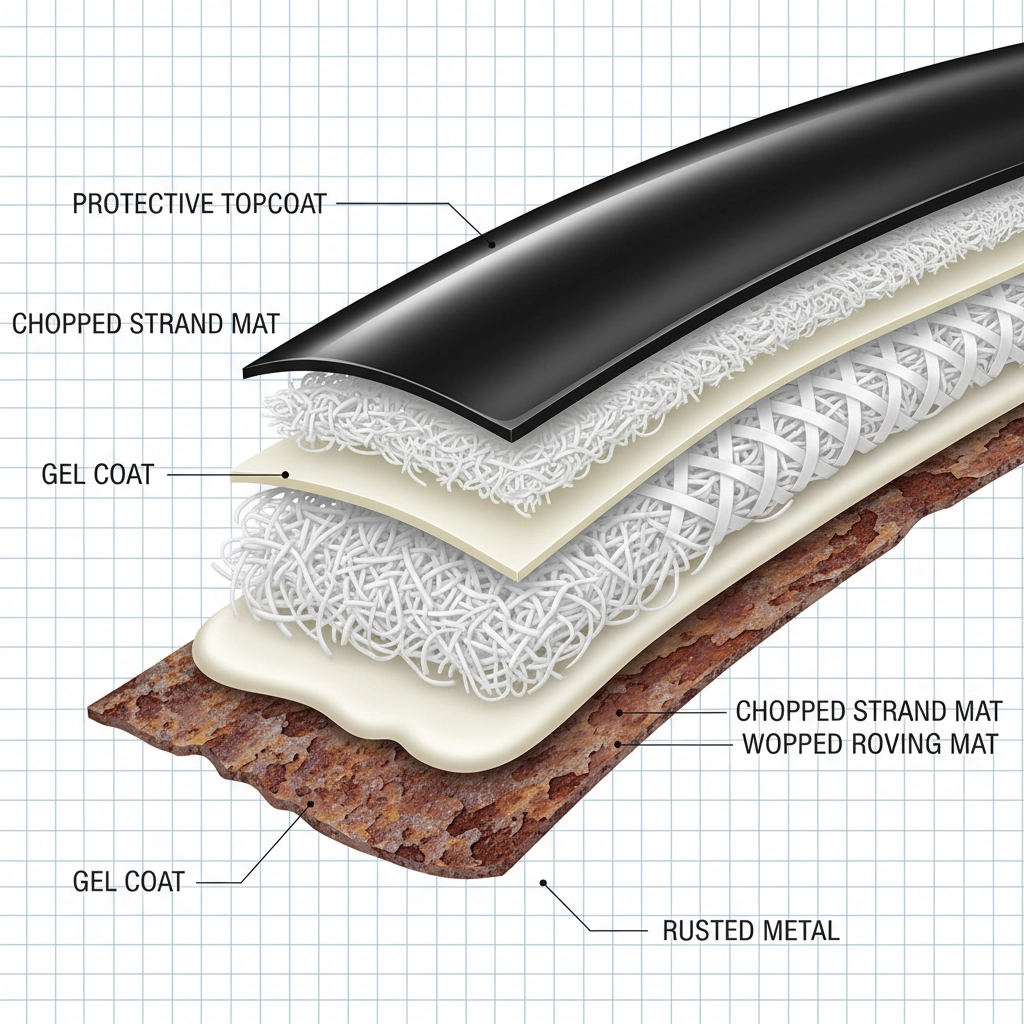

Fibreglass Laminate Repairs

For through-rust situations, fibreglass matting combined with polyester laminating resin offers a cost-effective solution that provides genuine structural strength. This approach is particularly effective for larger holes or areas where traditional body filler would be inadequate.

The process involves thorough surface preparation, application of gel coat, followed by multiple layers of fibreglass matting saturated with resin. When properly executed, fibreglass repairs can actually be stronger than the original steel, though they require different expansion characteristics to be considered.

Advanced Rust Conversion and Prevention Systems

Modern rust conversion chemistry has evolved significantly beyond simple "rust converters." Professional-grade systems like POR15 and Corroless actually chemically transform existing rust into a protective barrier, then provide a foundation for additional protective coatings.

These systems excel in situations where complete rust removal is impractical: such as inside closed sections or areas with extensive surface rust that hasn't penetrated completely through the material.

Critical Limitations: When Welding Becomes Essential

Structural Integrity Compromises

Any rust affecting load-bearing chassis rails, suspension mounting points, or safety-critical areas typically requires welding for proper repair. Non-welded repairs simply cannot restore the precise metallurgical properties required for these applications.

Structural rust repairs demand new steel to be precisely fitted and welded in place, often requiring significant disassembly to access affected areas properly. Attempting to address structural rust with non-welded methods can create dangerous safety hazards.

MOT and Safety Considerations

UK MOT regulations are specific about structural repairs: examiners are trained to identify non-appropriate repairs on safety-critical components. While non-welded repairs on non-structural areas are perfectly acceptable, attempting to mask structural issues with surface treatments can result in dangerous failures and MOT failures.

Professional MOT testers understand the difference between legitimate surface repairs and inappropriate attempts to conceal structural damage. Transparency about repair methods used is always the best approach.

Extensive Corrosion Patterns

When rust has spread extensively across multiple structural areas, the interconnected nature of chassis design means that piecemeal non-welded repairs become inadequate. Comprehensive structural repairs ensure that stress patterns are properly distributed across the chassis.

Professional Assessment: The Foundation of Effective Repairs

Comprehensive Inspection Requirements

Determining whether non-welded repairs are appropriate requires thorough inspection by experienced professionals. What appears as surface rust may actually indicate deeper structural issues that aren't immediately visible.

Professional inspection involves removing underbody coverings, cleaning affected areas, and using specialised tools to assess the true extent of corrosion. This process often reveals that apparently severe damage is actually repairable without welding: or conversely, that seemingly minor issues require structural attention.

Material Compatibility Considerations

Modern vehicles incorporate various steel grades, aluminium components, and advanced coatings that require specific repair approaches. Professional assessment ensures that repair materials are compatible with original construction methods and won't create galvanic corrosion issues.

Long-Term Cost Analysis

While non-welded repairs often cost significantly less initially, professional assessment helps determine whether they represent genuine long-term value. In some cases, proper welded repairs, though more expensive, provide better lifetime value than repeated non-welded interventions.

DIY Versus Professional Execution

Skill and Equipment Requirements

Successful non-welded rust repairs require significant skill in surface preparation, material selection, and application techniques. Professional workshops have access to specialised equipment for proper surface cleaning, controlled environments for curing, and experience with material compatibility.

DIY attempts often fail due to inadequate surface preparation or inappropriate material selection rather than inherent limitations of the repair methods themselves.

Quality Control and Warranties

Professional repairs typically include warranties and quality guarantees that DIY work cannot match. Established workshops like Rustec stake their reputation on repair longevity and can provide documentation that adds value during vehicle sales.

Safety and Environmental Considerations

Many effective rust repair materials involve hazardous chemicals that require proper handling, ventilation, and disposal procedures. Professional workshops have the facilities and training to manage these safely.

Making Informed Repair Decisions

The key to successful underbody rust management lies in accurate assessment, appropriate method selection, and quality execution. Non-welded repairs offer excellent solutions for many rust issues, but recognising their limitations prevents costly mistakes and potential safety hazards.

Quality non-welded repairs, properly executed, can extend vehicle life significantly while maintaining safety and MOT compliance. However, attempting to use these methods inappropriately: particularly on structural components: can create dangerous situations and ultimately cost more than proper welded repairs.

Expert Assessment and Honest Advice

At Rustec, we understand that every rust situation is unique, and the right repair approach depends on multiple factors including the vehicle's intended use, budget considerations, and long-term goals. Our comprehensive inspection process identifies exactly what can be effectively repaired without welding and where structural intervention is essential.

Don't gamble with your vehicle's safety or your investment. Contact Rustec today for professional assessment of your underbody rust concerns. Our experienced technicians provide honest, transparent advice about the most appropriate repair methods for your specific situation, ensuring you get the best possible outcome whether that involves advanced non-welded techniques or proper structural repairs.

Our commitment to quality means we'll never recommend unnecessary work, but we'll also never compromise on safety by suggesting inappropriate repair methods. Get the expert opinion you need to make informed decisions about your vehicle's future.

Comments