Can I paint over rust before undersealing?

- Lloyd Saunders

- Nov 22, 2025

- 4 min read

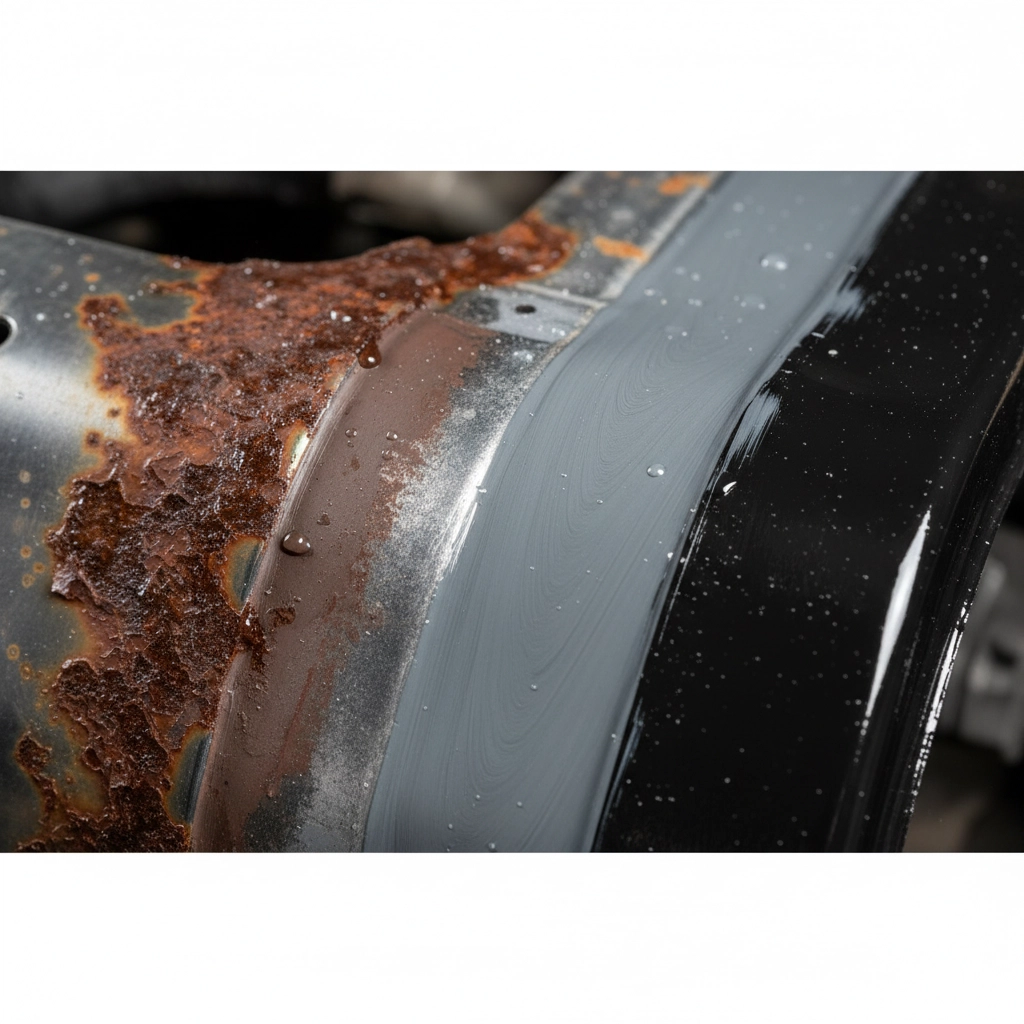

Yes, you can paint over rust before undersealing, but the sequence and products you choose are absolutely critical to preventing future corrosion problems. Many vehicle owners make the mistake of rushing this process or using incompatible products, which can actually accelerate rust formation rather than prevent it.

The short answer is that proper rust treatment and painting should be completed before applying any underbody protection. However, understanding the correct methodology and product compatibility is essential for long-term success.

The Correct Sequence for Rust Treatment and Undersealing

Professional rust prevention follows a precise sequence that cannot be shortcuts without compromising effectiveness:

Step 1: Comprehensive Rust Assessment and Removal Begin with thorough cleaning using wire brushes, steel wool, or mechanical means to remove loose rust, flaking paint, and debris. This step is crucial – any remaining loose material will continue to deteriorate beneath subsequent treatments.

Step 2: Surface Preparation Sand all treated areas with appropriate-grade sandpaper, paying particular attention to the boundaries where rust meets sound metal. This creates the mechanical bond necessary for primer adhesion and ensures smooth transitions between treated and untreated areas.

Step 3: Chemical Rust Treatment Apply a high-quality rust converter or neutralising primer specifically designed for automotive applications. These products chemically transform existing rust into a stable compound that prevents further oxidation.

Step 4: Protective Primer Application Once the rust converter has fully cured, apply a corrosion-resistant primer designed for metal surfaces. This creates the foundation for subsequent paint adhesion and provides additional barrier protection.

Step 5: Protective Paint Coating Apply exterior-grade metal paint in multiple thin coats rather than single thick applications. This ensures proper curing, maximum durability, and optimal protection against moisture penetration.

Step 6: Underbody Protection Application Only after complete paint curing should underbody protection be applied, and product selection here is critical for success.

Why Product Compatibility Matters

The relationship between paint and underseal products is complex and poorly understood by many DIY enthusiasts. Traditional bitumen-based underseals and some wax-type coatings can create moisture traps when applied over painted surfaces, leading to accelerated corrosion rather than protection.

Problematic Combinations:

Heavy bitumen underseals over paint

Cheap wax-based products without proper adhesion properties

Rubberised coatings that lack breathability

Compatible Systems: Modern underbody protection systems such as Dinitrol's range of products are specifically formulated to work effectively over properly prepared painted surfaces. These advanced formulations provide superior corrosion resistance without creating the moisture-trapping issues associated with older technologies.

Professional vs DIY Considerations

While the theoretical process appears straightforward, achieving professional-grade results requires significant expertise, proper equipment, and access to premium-quality products.

DIY Limitations:

Difficulty accessing all rust-prone areas without proper lifting equipment

Incomplete rust removal due to limited visibility and tools

Product application inconsistencies leading to coverage gaps

Inadequate surface preparation affecting long-term durability

Limited access to professional-grade materials

Professional Advantages:

Comprehensive inspection capabilities to identify all affected areas

Access to professional-grade rust treatment and protection products

Proper application equipment ensuring consistent coverage

Experience with product compatibility and optimal application techniques

Lifetime guarantees on workmanship and materials

The Rustec Professional Approach

At Rustec, our comprehensive rustproofing process addresses every aspect of rust prevention, from initial assessment through to long-term maintenance planning.

Our Methodology:

Detailed pre-treatment inspection identifying all current and potential rust sites

Thorough undercarriage cleaning removing salt, debris, and loose materials

Professional rust treatment using premium Dinitrol products

Systematic application ensuring complete coverage of all vulnerable areas

Quality control verification with photographic documentation

Post-treatment inspection confirming treatment effectiveness

Our technicians understand the critical importance of proper surface preparation and product sequencing. When rust treatment and painting are required, we ensure complete compatibility between all applied systems, eliminating the risk of moisture entrapment or chemical incompatibility.

Understanding Different Underseal Types

Not all underbody protection products are created equal, and understanding these differences is crucial when planning treatment over painted surfaces.

Dinitrol Systems:

ML (Cavity Wax): Penetrating protection for enclosed spaces

4941: Thixotropic underbody compound suitable for painted surfaces

RC900: High-build protective coating for extreme conditions

Each Dinitrol product is formulated for specific applications and substrate compatibility, ensuring optimal performance when applied according to manufacturer specifications.

Traditional Products: Older underseal technologies including heavy bitumen compounds and basic wax systems often lack the sophisticated chemistry required for compatibility with painted surfaces, leading to long-term adhesion and moisture-related problems.

Critical Success Factors

Several factors determine the success of painting over rust before undersealing:

Surface Preparation Quality: Inadequate rust removal or surface preparation inevitably leads to treatment failure, regardless of product quality.

Product Selection: Choosing compatible rust treatment, primer, paint, and underseal systems prevents chemical incompatibility issues.

Application Timing: Allowing adequate curing time between each treatment stage ensures optimal adhesion and performance.

Environmental Conditions: Temperature, humidity, and contamination during application significantly affect treatment success.

Coverage Completeness: Even small gaps in treatment coverage can become initiation points for future corrosion.

When Professional Treatment Is Essential

Certain situations demand professional intervention regardless of DIY capabilities:

Structural rust affecting chassis integrity

Extensive corrosion requiring welding or fabrication work

Classic or high-value vehicles where mistakes could be costly

Commercial vehicles requiring documented treatment for compliance

Situations where lifetime protection guarantees are needed

Common Mistakes to Avoid

Rushing the Process: Each treatment stage requires adequate curing time for optimal effectiveness.

Product Mixing: Combining incompatible products can create chemical reactions that compromise protection.

Inadequate Preparation: Shortcuts in rust removal or surface preparation guarantee premature failure.

Coverage Gaps: Incomplete treatment coverage creates corrosion initiation points.

Environmental Neglect: Applying treatments in unsuitable weather conditions affects curing and performance.

Long-Term Maintenance Considerations

Even professional-grade rust treatment and undersealing requires ongoing maintenance for optimal longevity. Regular inspection, particularly after winter months when road salt exposure is highest, allows early identification of any treatment degradation.

Professional maintenance services ensure continued effectiveness through systematic inspection, touch-up treatments where necessary, and proactive protection of newly vulnerable areas.

Making the Right Choice

While painting over rust before undersealing is technically possible and often necessary, the complexity of achieving long-lasting results makes professional treatment the preferred option for most vehicle owners.

Rustec's comprehensive approach eliminates the risks associated with DIY treatment while providing lifetime protection guarantees and ongoing maintenance support. Our experienced technicians understand the intricacies of rust treatment sequencing and product compatibility, ensuring optimal results that protect your investment for years to come.

For vehicles requiring rust treatment before protective undersealing, professional assessment and treatment provide the confidence that comes with expert application and comprehensive warranties. Contact our team to discuss your specific requirements and discover how our proven methodology can provide the long-term protection your vehicle deserves.

Comments