Best rustproofing methods in the UK

- Lloyd Saunders

- Nov 1, 2025

- 4 min read

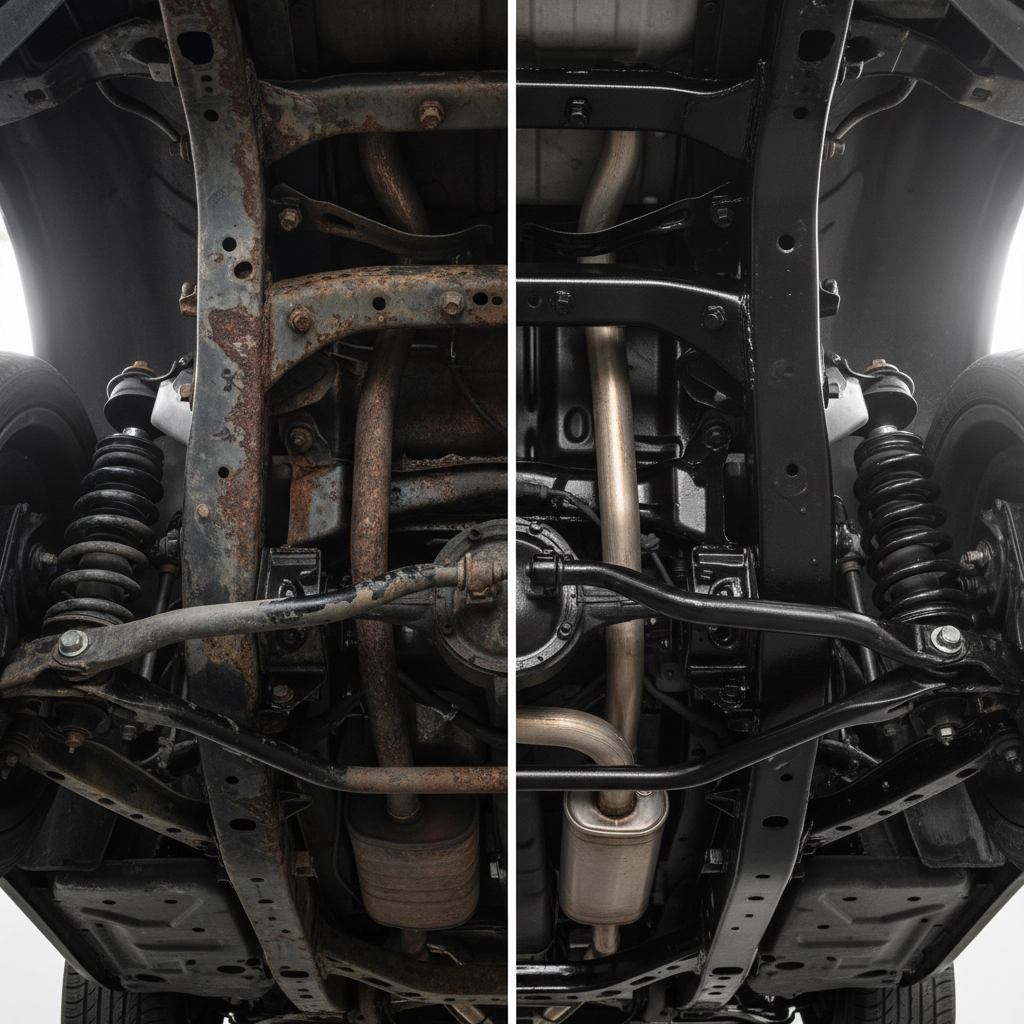

Selecting the most effective rustproofing method for your vehicle requires understanding the comprehensive range of professional treatments available. In the UK's challenging climate conditions, combining multiple rustproofing approaches delivers superior long-term protection against corrosion damage.

Professional Spray-On Rustproofing Systems

Dinitrol spray-on treatments represent the premium standard in professional rustproofing. The Dinitrol 4941 system provides exceptional penetration into metal surfaces, creating a durable protective barrier that prevents moisture ingress. This German-engineered solution offers superior adhesion properties and maintains flexibility across temperature variations common in UK conditions.

Professional application ensures complete coverage of vulnerable areas including chassis rails, suspension components, and structural elements. The treatment penetrates existing surface oxidation while forming a long-lasting protective seal. Life Long Dinitrol® treatments provide comprehensive protection when applied by certified technicians using proper surface preparation and application techniques.

Lanoguard lanolin-based systems offer an environmentally sustainable alternative with excellent self-healing properties. The natural lanolin formula provides ongoing protection by flowing into scratches and minor damage areas. Professional application involves thorough surface cleaning followed by controlled spray application to achieve optimal film thickness.

Cavity Wax Injection Systems

Dinitrol ML cavity wax injection represents the most thorough approach to internal structural protection. This technique involves accessing hollow sections within doors, sills, chassis members, and structural pillars through existing drainage holes or purpose-made access points.

The injection process ensures complete internal coverage of areas where conventional external treatments cannot reach. Cavity wax treatments displace existing moisture while providing long-term corrosion inhibition. Professional technicians use specialised injection equipment to achieve proper distribution throughout internal cavities.

Key injection points include:

Door frames and internal structures

A-pillar and B-pillar cavities

Sill sections and structural channels

Chassis box sections and cross members

Tailgate and bonnet internal areas

Advanced Underbody Protection Methods

Comprehensive underbody treatments combine mechanical preparation with premium protective coatings. The process begins with thorough undercarriage steam cleaning to remove road salt, debris, and existing degraded coatings. Meticulous surface preparation ensures optimal adhesion of subsequent treatments.

Following cleaning, existing rust receives treatment with high-performance rust converters that chemically stabilise oxidation. Professional-grade products like Jenolite Rust Converter or Bilt Hamber Hydrate-80 transform rust into a stable protective layer suitable for overcoating.

Epoxy primer application follows rust conversion, providing waterproof adhesion and superior corrosion resistance. Two-coat application ensures complete coverage and optimal protection performance. Final sealing involves polyurethane-based sealants applied to welded joints, seam areas, and potential moisture entry points.

Rubberised Underbody Coatings

Professional rubberised underseal provides impact protection combined with moisture barrier properties. Modern formulations offer flexibility and durability while maintaining effective coverage over irregular surfaces. Black rubberised coatings deliver visual uniformity and professional appearance.

Application requires controlled temperature conditions and proper surface preparation for optimal adhesion. Professional spray equipment ensures consistent film thickness and complete coverage of underbody surfaces. Clear protective coatings offer corrosion protection while maintaining visibility of underlying components for inspection purposes.

Wax-Based Protection Systems

Traditional wax-based treatments like Waxoyl continue providing effective protection when professionally applied. Modern application techniques involve heating for improved penetration and coverage. Professional wax application ensures proper surface preparation and controlled application conditions.

Wax treatments offer self-healing properties and excellent water displacement characteristics. Regular maintenance and reapplication schedules maintain long-term effectiveness. Combination treatments utilising both wax-based cavity protection and spray-on external coatings deliver comprehensive protection strategies.

Multi-Stage Professional Treatment Approach

Premium rustproofing packages combine multiple treatment methods for maximum protection effectiveness. The comprehensive approach includes:

Stage 1: Inspection and Preparation

Comprehensive undercarriage assessment

Photo documentation of existing condition

Thorough steam cleaning and degreasing

Rust treatment and surface preparation

Stage 2: Internal Protection

Cavity wax injection to all accessible hollow sections

Dinitrol ML application to critical structural areas

Drainage hole clearing and protection

Stage 3: External Treatment

Professional spray application of premium protective coatings

Underbody sealing of joints and vulnerable areas

Final protective coating application

Method Selection Guidelines

Vehicle age and condition determine optimal treatment selection. New vehicles benefit from preventive cavity wax treatments combined with external protection. Older vehicles require comprehensive rust treatment followed by multi-layer protection systems.

Usage patterns influence method selection. Daily drivers require durable treatments resistant to frequent washing and weather exposure. Classic vehicles benefit from traditional wax-based systems with regular maintenance schedules. Commercial vehicles need heavy-duty protection against intensive usage conditions.

Environmental factors affect treatment choice. Coastal locations require enhanced protection against salt spray exposure. Urban environments need protection against road salt and pollution. Rural usage benefits from treatments resistant to agricultural chemicals and debris damage.

Professional Application Advantages

Certified technician application ensures proper surface preparation, optimal product selection, and correct application techniques. Professional equipment delivers consistent coverage and appropriate film thickness for maximum protection effectiveness.

Quality control procedures include comprehensive inspection protocols and photo documentation throughout the treatment process. Professional warranties provide confidence in treatment durability and performance.

Specialist knowledge enables proper product selection for specific vehicle requirements and usage conditions. Technical expertise ensures compatibility between different treatment systems and existing vehicle components.

Treatment Longevity and Maintenance

Premium professional treatments typically provide 5-10 years of effective protection depending on usage conditions and maintenance. Regular inspection schedules ensure ongoing protection effectiveness and identify areas requiring attention.

Maintenance procedures include periodic cleaning, drainage hole clearing, and top-up treatments for high-wear areas. Professional maintenance services ensure continued protection throughout vehicle ownership.

Performance monitoring through regular comprehensive inspections identifies potential issues before significant damage occurs. Proactive maintenance extends treatment life and maintains protection effectiveness.

Investment Value and Protection Benefits

Professional rustproofing investment significantly reduces long-term maintenance costs and preserves vehicle value. Comprehensive protection prevents expensive structural repairs and MOT failures related to corrosion damage.

Resale value protection through maintained structural integrity and visual condition provides excellent return on investment. Insurance considerations may recognise professional rustproofing as risk reduction for comprehensive coverage.

Peace of mind from knowing your vehicle receives premium protection against UK climate challenges ensures confident vehicle ownership and usage.

Choose Rustec for Professional Excellence

Rustec delivers premium rustproofing solutions using the highest-quality products including Life Long Dinitrol® treatments. Our comprehensive inspection and meticulous application processes ensure your vehicle receives optimal protection against corrosion damage.

Professional certification and specialist expertise guarantee proper treatment selection and application for your specific requirements. Complete transparency through photo documentation and detailed service records provides confidence in treatment quality.

Book your comprehensive rustproofing consultation today and discover why vehicle owners across the UK trust Rustec's premium protection services. Enquire by filling out the quick quote box below or contact our specialist team for expert advice on the optimal rustproofing solution for your vehicle.

Protect your investment with professional rustproofing excellence – your vehicle deserves the comprehensive protection that only certified professional treatment can provide.

Comments